Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Affordable Impeller Water Pump Pricing and Options for Every Budget

Understanding Impeller Water Pump Prices What Influences the Cost?

When searching for an impeller water pump, consumers often find themselves grappling with a myriad of options and prices. Impeller water pumps are essential mechanical devices used in a wide range of applications, from agricultural irrigation to industrial processes and household plumbing. The price of these pumps can vary significantly based on several key factors.

1. Type of Impeller Pump

There are various types of impeller pumps, such as centrifugal pumps, submersible pumps, and jet pumps, each designed for specific uses. Centrifugal pumps, for example, are commonly used for high flow applications, while submersible pumps are necessary for pumping water from deep wells. The complexity and design of the pump play a crucial role in determining its price. Generally, specialized types of pumps equipped with advanced features tend to be more expensive.

The materials used in manufacturing impeller water pumps greatly influence their durability and efficiency, thereby affecting the price. Pumps made from high-grade stainless steel or bronze are typically more expensive than those made from plastic or lower-grade materials. This is because higher-quality materials offer greater longevity and resistance to corrosion, which can save costs in the long run due to reduced maintenance and replacement needs.

3. Brand Reputation

The brand behind an impeller water pump can have a substantial impact on pricing. Established brands with a long history of reliability and performance often command higher prices due to their reputation. Customers frequently perceive these brands as providing better quality and longer-lasting products. On the other hand, less well-known brands may offer lower prices, but they may not deliver the same level of reliability or customer service.

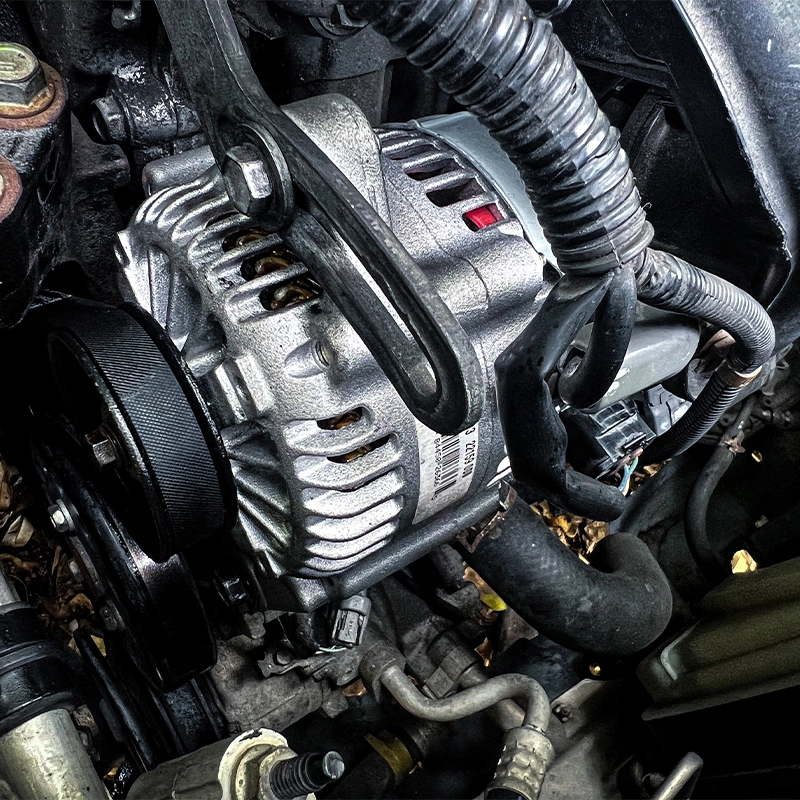

impeller water pump price

4. Pump Capacity and Performance Ratings

The capacity of an impeller water pump is another determinant of price. Pumps with higher flow rates and better pump heads, which indicate how high the pump can lift water, typically come at a premium. The performance ratings, including horsepower, efficiency ratings (like the Best Efficiency Point or BEP), and the design of the impeller itself, are critical specifications that impact cost. Pumps designed for heavy-duty or industrial applications will often be priced higher than those intended for light residential use.

5. Additional Features and Technology

Modern impeller pumps may come with a variety of features that enhance their functionality, such as variable speed drives, automatic shut-off mechanisms, or smart technology for remote monitoring. These additional features, while increasing convenience and efficiency, also contribute to higher costs. When considering price, customers should evaluate whether these features are necessary for their specific applications.

6. Market Conditions and Supply Chain Factors

Finally, market conditions play a significant role in the pricing of impeller water pumps. Fluctuations in material costs, transportation expenses, and even global supply chain disruptions can affect the final price paid by consumers. Seasonal demand can also impact prices; for instance, during dry seasons, the demand for irrigation pumps may drive prices up.

Conclusion

When looking to purchase an impeller water pump, understanding the factors that influence pricing is essential. Prices can vary widely based on the type of pump, material quality, brand reputation, capacity, additional features, and current market conditions. By carefully evaluating your specific needs and comparing different options, you can find a reliable impeller water pump that fits both your budget and requirements. Whether for home use or industrial applications, investing in the right pump is crucial for efficiency and performance.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025