Mobile:+86-311-808-126-83

Email:info@ydcastings.com

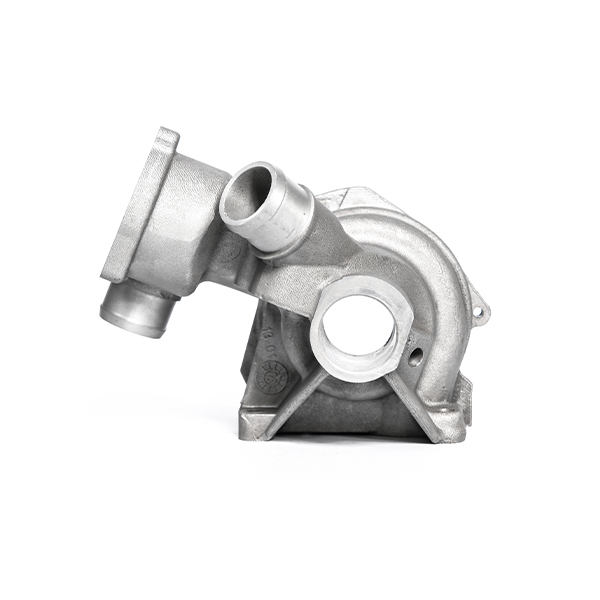

a356 investment casting

A356 Investment Casting The Cornerstone of Precision Engineering

Investment casting, also known as lost-wax casting, is a sophisticated process that allows for the creation of complex shapes with precise dimensions. One of the most sought-after alloys used in this casting method is A356 aluminum. This alloy has gained widespread popularity in various industries due to its excellent mechanical properties, corrosion resistance, and ability to be cast into intricate shapes with smooth finishes.

Understanding A356 Aluminum Alloy

A356 aluminum is primarily composed of aluminum, silicon, and magnesium, which contribute to its mechanical strength and lightweight characteristics. The addition of silicon improves the fluidity of the molten metal, making it easier to cast intricate designs. A356 has a high strength-to-weight ratio, making it ideal for applications in the aerospace, automotive, and marine industries, among others. Moreover, it exhibits excellent weldability and machinability, which further enhances its applicability in precision engineering.

The Investment Casting Process

The investment casting process involves several key steps

1. Pattern Creation The process begins with the creation of a wax pattern representing the final product. This pattern is typically made from a high-quality wax that can withstand the heat of the molten metal.

2. Molding The wax pattern is coated with a ceramic shell that is gradually built up through repeated dipping and dusting processes. Once the shell is sufficiently thick, it is heated to melt away the wax, leaving a hollow ceramic mold.

3. Pouring The next step is to pour the A356 molten aluminum into the ceramic mold. Due to its excellent fluidity, A356 can fill complex geometries that other alloys might struggle with, ensuring high fidelity to the original pattern.

4. Cooling and Shell Removal After the metal has cooled and solidified, the ceramic shell is removed, revealing the cast part. This process often results in a near-net-shape component, requiring minimal machining.

5. Finishing The final stage involves cleaning, grinding, or machining the cast part to achieve the desired specifications and finish.

Advantages of A356 Investment Casting

The use of A356 aluminum in investment casting offers several advantages

a356 investment casting

1. Complex Shapes One of the primary benefits of investment casting is its ability to produce highly complex geometries. A356 aluminum’s fluidity during casting allows designers to explore innovative shapes that would be difficult or impossible to achieve through other manufacturing methods.

2. Superior Surface Finish The investment casting process results in a smooth surface finish, reducing or even eliminating the need for extensive post-processing. This is especially beneficial in industries where aesthetics are important.

3. Cost-Effectiveness While the upfront costs of creating molds for investment casting can be high, the process is often economical for large production runs. The minimal waste produced during casting and reduced machining requirements can lead to lower overall manufacturing costs.

4. Lightweight yet Strong A356 aluminum’s inherent properties provide a lightweight solution without compromising strength. This quality makes it particularly valuable in sectors like aerospace, where weight reduction is critical.

5. Corrosion Resistance A356 aluminum is naturally resistant to corrosion, making it suitable for applications that require durability in harsh environments. This resistance extends the lifespan of manufactured components, reducing the frequency of replacements.

Applications of A356 Investment Casting

A356 investment casting is employed in a variety of applications, including

- Automotive Components Engine blocks, suspension arms, and transmission housings benefit from A356’s strength and lightweight properties, contributing to overall vehicle efficiency.

- Aerospace Parts The aerospace industry utilizes A356 for components like brackets and housings, where precision and weight savings are pivotal.

- Marine Applications Due to its corrosion resistance, A356 is an excellent choice for ship parts and other marine engineering applications.

- Industrial Equipment Various machinery components, such as pumps and valve bodies, rely on the durability and performance of A356 aluminum.

Conclusion

In conclusion, A356 investment casting presents a robust solution for industries requiring precision, complexity, and performance. Its unique properties and advantages make it a powerhouse in the realm of manufacturing, driving innovations and efficiency across multiple sectors. As technology continues to advance, the use of A356 aluminum in investment casting is likely to grow, leading to even more refined and high-performing products in the market.