Mobile:+86-311-808-126-83

Email:info@ydcastings.com

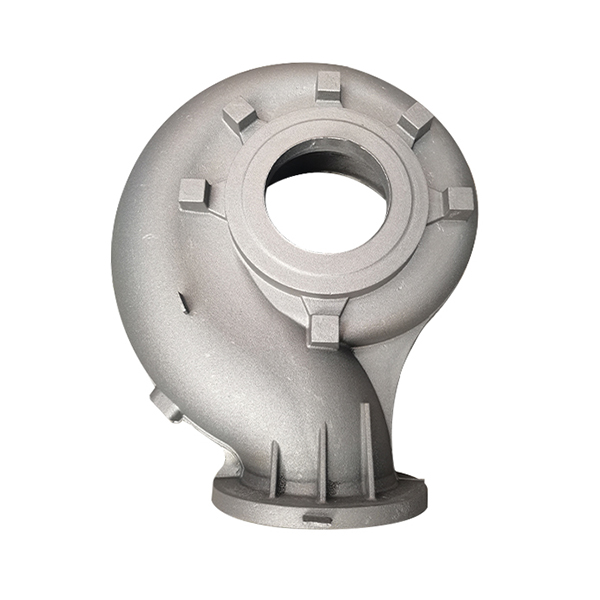

7.3 turbo compressor housing

Understanding the 7.3% Turbo Compressor Housing Features, Benefits, and Applications

In the realm of modern engineering, turbo compressors play a pivotal role across various industries, from automotive to aerospace. At the heart of these machines lies an essential component known as the turbo compressor housing. In this article, we will delve into the specifications, advantages, and applications of the 7.3% turbo compressor housing, underscoring its importance in enhancing performance and efficiency.

What is a Turbo Compressor Housing?

The turbo compressor housing is a critical structural component that encases the turbine and compressor elements of the turbocharger. Its primary function is to provide a controlled environment for air compression while ensuring durability and heat resistance. The design of the housing significantly influences the turbocharger’s efficiency, responsiveness, and overall performance.

The Significance of the 7.3% Variant

The term “7.3%” refers to a specific efficiency rating associated with this turbo compressor housing. This rating indicates that the turbocharger achieves an efficiency level of 7.3% in converting the energy produced by the engine into compressed air. In the context of turbochargers, even a small percentage increase in efficiency can lead to significant improvements in engine performance, fuel economy, and emissions.

Features of the 7.3% Turbo Compressor Housing

1. Optimized Airflow Design The 7.3% turbo compressor housing is engineered with advanced aerodynamic principles in mind. Its contours and internal geometry minimize turbulence and pressure drops, thereby enhancing the flow of air into the engine.

2. Durability and Heat Resistance Constructed from high-grade materials, the housing withstands extreme temperatures and pressures, making it reliable for high-performance applications. This durability ensures longevity and reduces the need for frequent replacements or maintenance.

3. Compact Design The housing is designed to be compact yet efficient, making it suitable for various engine sizes and configurations. This versatility allows manufacturers to integrate it into a broad range of applications without compromising on performance.

4. Noise Reduction Features Modern turbo compressor housings often incorporate design elements that reduce the noise generated during operation. This feature enhances the driving experience without sacrificing performance.

7.3 turbo compressor housing

Benefits of Utilizing the 7

.3% Turbo Compressor Housing1. Enhanced Efficiency With an efficiency rating of 7.3%, this turbo compressor housing significantly improves the overall performance of the engine. Enhanced air compression leads to better combustion, resulting in increased power output with less fuel consumption.

2. Improved Fuel Economy Vehicles equipped with the 7.3% variant benefit from better fuel efficiency. By maximizing the energy derived from combustion, drivers can experience longer distances per gallon, contributing to lower operating costs.

3. Reduced Emissions A more efficient combustion process translates to lower emissions of harmful pollutants. This feature is crucial in meeting stringent environmental regulations and promoting sustainable practices.

4. Increased Reliability The robust construction of the 7.3% turbo compressor housing ensures that it can endure the demanding conditions present in high-performance settings. This reliability translates to less downtime and higher productivity in various applications.

Applications of the 7.3% Turbo Compressor Housing

The versatility of the 7.3% turbo compressor housing allows it to be utilized in several key areas

- Automotive Industry Performance cars and trucks benefit greatly from this technology as manufacturers aim to meet customer desires for power and efficiency. - Aerospace Turbo compressors are vital for aircraft engines, providing necessary thrust and efficiency under varying atmospheric conditions. - Industrial Applications Manufacturing plants and facilities employing heavy machinery utilize turbo compressors for enhanced operational efficiency, especially in systems that require compressed air.

Conclusion

The 7.3% turbo compressor housing stands as an exemplary component in modern engineering, merging durability with remarkable performance enhancements. As industries continue to seek ways to improve efficiency and reduce their carbon footprint, innovations in turbo compressor housing design will remain at the forefront of technological development.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025