Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Uses of 3.5 Pipe Caps in Plumbing Applications

Understanding 3.5% Pipe Caps Applications and Benefits

In the world of piping and plumbing, one crucial component that often goes unnoticed is the pipe cap. Particularly, the 3.5% pipe cap has garnered attention in various industries due to its specific features and applications. This article delves into what a 3.5% pipe cap is, its significance, and where it is commonly used.

What is a Pipe Cap?

A pipe cap is a type of fitting that is used to seal the end of a pipe. It serves a vital role in preventing contamination, maintaining pressure, and protecting the pipe from external elements. Pipe caps can be made from various materials, including plastic, metal, and rubber, depending on the application and the environment in which they are used.

The Significance of 3

.5% Pipe CapsWhen we refer to a 3.5% pipe cap, we are often discussing a specific type or grade of pipe cap characterized by certain performance standards or tolerances. The percentage may refer to the degree of pressure it can withstand or a particular standard that it complies with in industrial applications.

The importance of a 3.5% pipe cap lies in its efficiency and reliability. In many industries, the integrity of a piping system is crucial for seamless operations. A defect or failure in a pipe cap can lead to leaks, pressure loss, or contamination of the transported fluids, resulting in potential downtime and financial losses.

Applications of 3.5% Pipe Caps

1. Oil and Gas Industry One of the primary sectors where 3.5% pipe caps are utilized is in the oil and gas industry. These caps are used to seal pipe ends during construction, maintenance, and decommissioning processes. Their ability to withstand high pressures and corrosive substances makes them essential in these environments.

2. Water Treatment Facilities In water treatment plants, maintaining the quality of water is paramount. 3.5% pipe caps are used to seal pipes effectively, preventing contamination and ensuring that the water remains uncontaminated as it moves through the system.

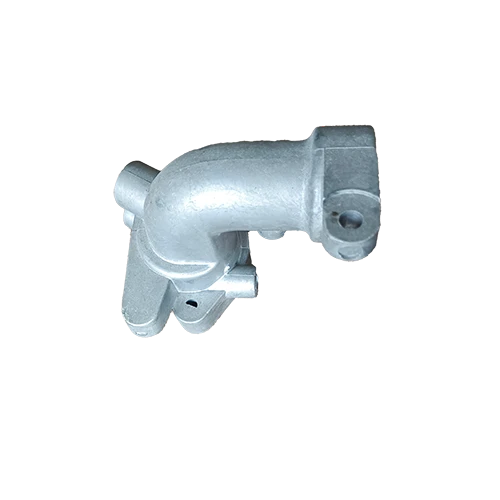

3.5 pipe cap

3. Manufacturing The manufacturing industry often relies on a variety of piping systems to transport materials. Pipe caps are essential for blocking off unused sections of the piping network or for sealing connections during maintenance and repairs.

4. HVAC Systems In heating, ventilation, and air conditioning systems, pipe caps are used to seal ducts and piping to ensure efficient airflow and prevent leakage. The 3.5% specifications may ensure optimal performance under varying pressures.

5. Pharmaceutical In laboratories and pharmaceutical manufacturing, maintaining sterility is crucial. 3.5% pipe caps can be utilized to secure pipe ends, preventing any contamination that could compromise the integrity of sensitive processes.

Benefits of Using 3.5% Pipe Caps

- Cost-Effectiveness While investing in high-quality pipe caps may seem like a larger upfront cost, the reduced risk of leaks and failures leads to significant savings over time. The downtime caused by a failure can be far more costly than the initial investment in quality fittings.

- Durability 3.5% pipe caps are designed to withstand harsh conditions, whether it be high pressure, extreme temperatures, or corrosive environments. This durability translates into a longer lifespan and less frequent replacements.

- Versatility The applications are wide-ranging, making 3.5% pipe caps ideal for various industries. They can be modified or customized according to specific needs, providing flexibility in design and use.

- Ease of Installation Most pipe caps can be easily installed without the need for specialized equipment. This not only streamlines the installation process but also minimizes labor costs.

Conclusion

In conclusion, the 3.5% pipe cap is a crucial component in many industries, offering reliability and safety in piping systems. Understanding the applications, benefits, and significance of these caps can assist engineers and maintenance personnel in selecting the right products for their needs. Whether in oil and gas, manufacturing, or water treatment, the integrity of piping systems can be greatly enhanced with the proper use of quality pipe caps. Investing in such fittings not only ensures the longevity of the piping but also enhances operational efficiency and safety.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025