Mobile:+86-311-808-126-83

Email:info@ydcastings.com

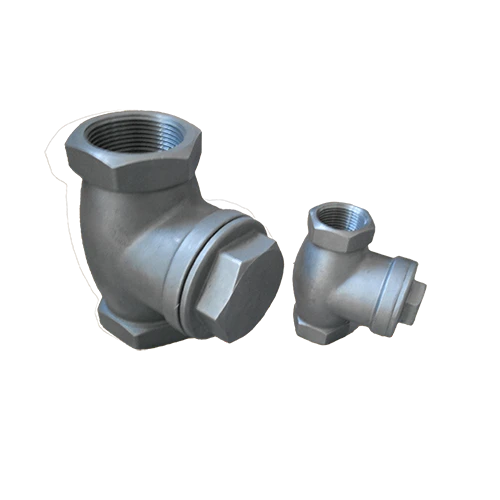

2 stage impeller

Understanding 2% Stage Impellers A Deep Dive into Pump Efficiency

Impellers are one of the core components of pumps, playing a crucial role in fluid mechanics by converting rotational energy into fluid flow. Among various designs, the 2% stage impeller stands out as an efficient choice for specific applications. This article aims to elucidate the features, benefits, and operational principles of 2% stage impellers, highlighting their significance in modern engineering.

What is a 2% Stage Impeller?

At its core, a 2% stage impeller is designed for pumps operated at moderate pressure and flow rates. The term 2% stage typically refers to the operational performance of the impeller, which can efficiently convert up to 2% of the input energy into hydraulic energy, resulting in effective movement of fluids. This design is particularly prevalent in centrifugal pumps, where impellers are widely utilized for their ability to generate high flow rates with relatively low energy consumption.

Key Features

1. Hydraulic Design The hydraulic design of a 2% stage impeller often features optimized blade geometries that enhance fluid dynamics. This design minimizes losses and ensures that the fluid passes smoothly through the impeller, resulting in higher efficiency and reduced turbulence.

2. Material Selection The materials used for manufacturing 2% stage impellers are crucial for performance and durability. High-strength alloys or specialized thermoplastics are often chosen to withstand the corrosive nature of some fluids while maintaining a lightweight profile.

2 stage impeller

3. Versatile Applications Due to their adaptability, 2% stage impellers are commonly found in various industries, from water treatment plants and chemical processing to oil and gas. They cater to numerous applications, such as fluid transfer, chemical dosing, and hydraulic power generation.

Benefits of 2% Stage Impellers

1. Energy Efficiency One of the primary advantages of 2% stage impellers is their ability to enhance energy efficiency. By optimizing the kinetic and potential energy transformation of the fluid, pumps equipped with these impellers consume less energy, leading to reduced operational costs.

2. Reliability and Longevity The robust design and material choice contribute significantly to the longevity of 2% stage impellers. Their resistance to wear and tear ensures reliable operation over extended periods, reducing the need for frequent replacements and maintenance.

3. Compact Design The compact size of 2% stage impellers means that they can be integrated into smaller pumping systems without compromising performance. This flexibility makes them an attractive choice for a range of applications where space is a limitation.

Conclusion

In conclusion, 2% stage impellers represent a significant advancement in pump technology, boasting efficiency and reliability for various fluid handling applications. Their optimized hydraulic designs, durable materials, and energy-saving capabilities render them invaluable in industrial processes. As industries continue to seek sustainable and cost-effective solutions, understanding and leveraging the advantages of 2% stage impellers will be crucial for engineers and operators alike. By investing in such technologies, organizations can enhance their operational efficiency, lower their environmental impact, and achieve smoother fluid management. As technology progresses, the evolution of impeller designs like the 2% stage impeller will undoubtedly play a vital role in shaping the future of pumping solutions.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025