Mobile:+86-311-808-126-83

Email:info@ydcastings.com

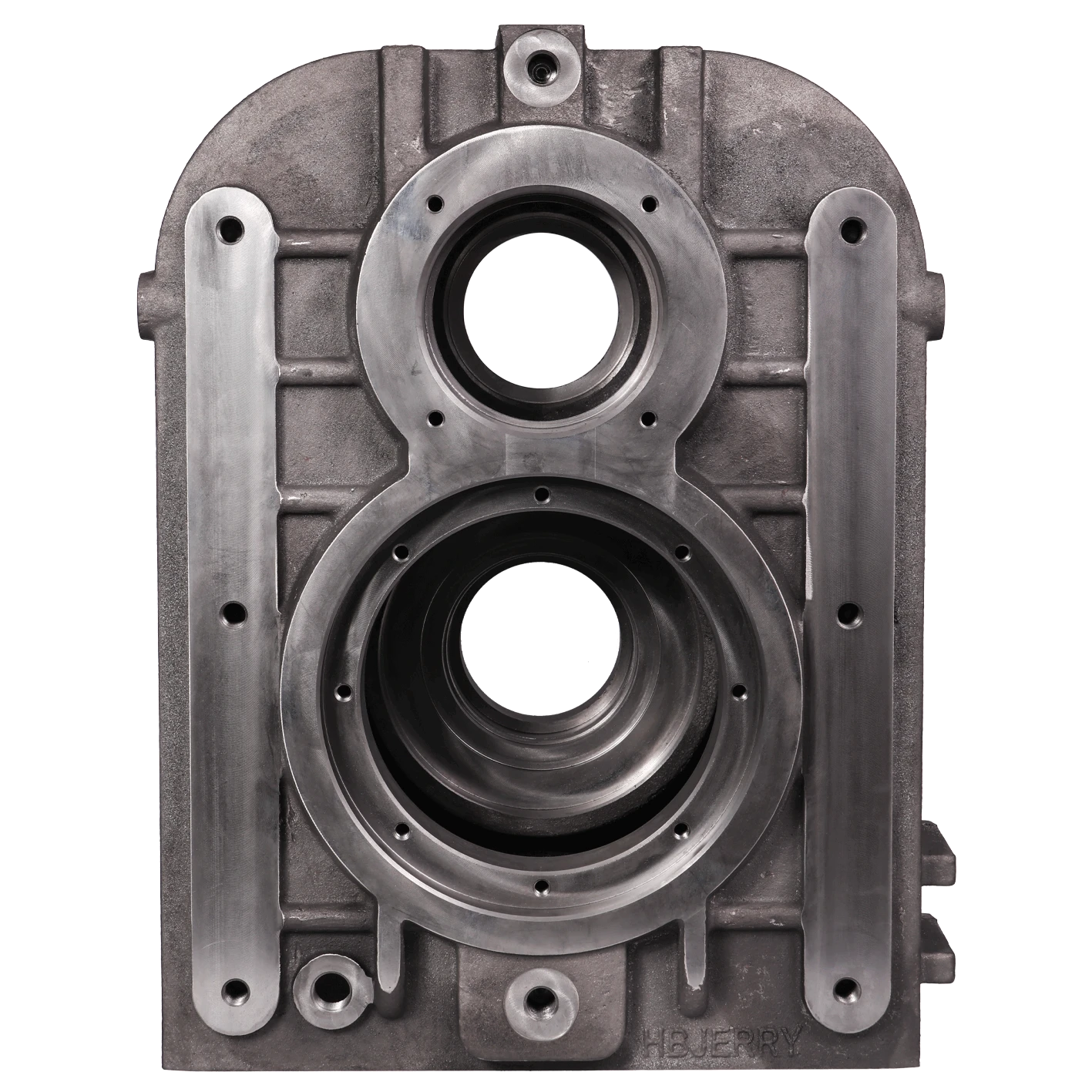

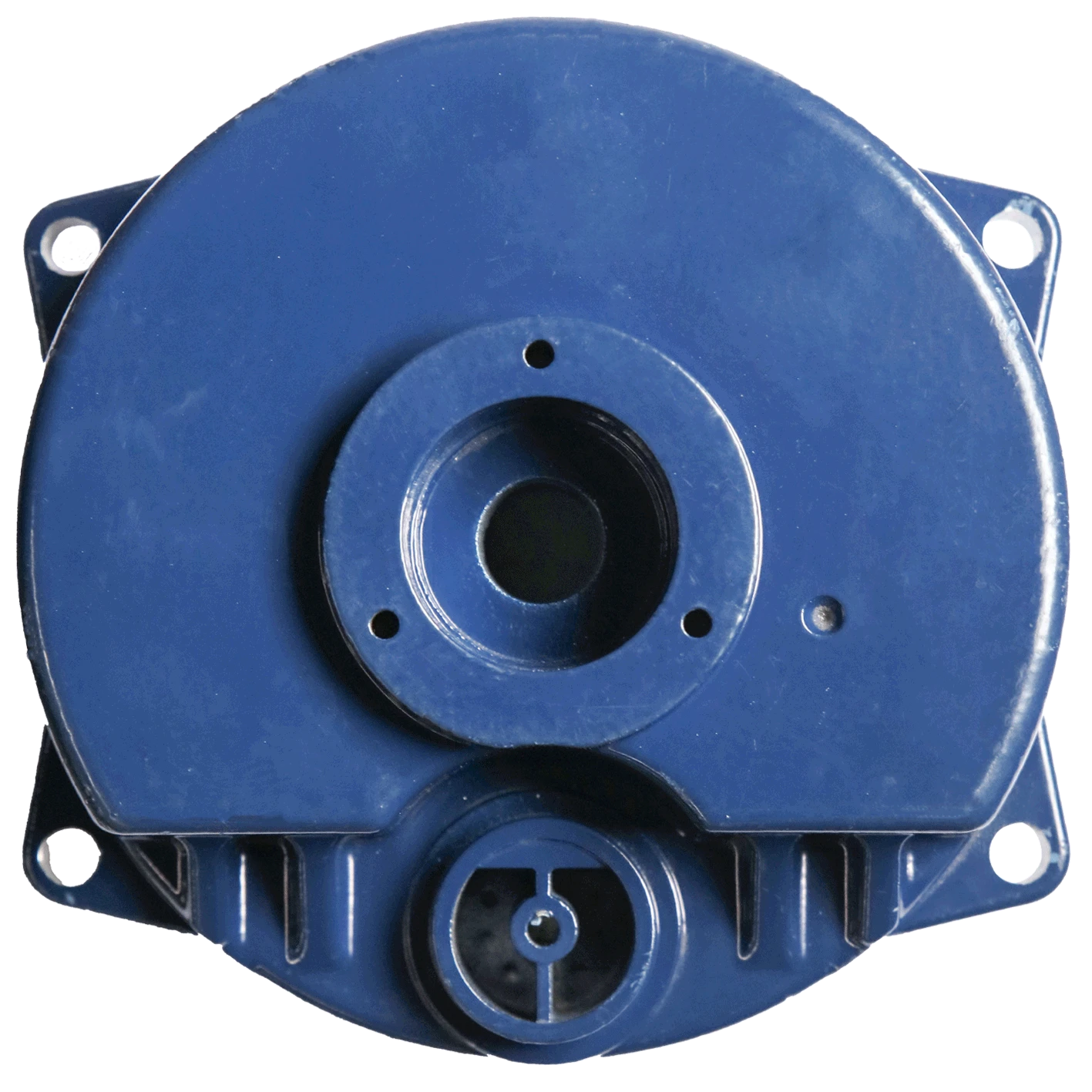

1 2 inch end cap

Understanding the 1% 202% Inch End Cap A Comprehensive Overview

In the world of manufacturing and engineering, seemingly small components can play crucial roles in ensuring the efficiency and functionality of larger systems. One such component is the end cap. In particular, this article focuses on the 1% 202% inch end cap, a defining feature in numerous applications across various industries. While the numbers may seem technical, understanding their significance can be invaluable for engineers, manufacturers, and DIY enthusiasts alike.

What is an End Cap?

An end cap is a fitting used to seal the open ends of a pipe or a tube. It serves both functional and aesthetic purposes, preventing contaminants from entering the pipe while also providing a clean finish. End caps come in various sizes and materials, ensuring compatibility with different types of piping systems. The dimensions and specifications dictate how effectively an end cap performs its role, making the details crucial for both design and application.

The 1% and 202% Measurements Explained

The designation of “1% 202% inch” can initially be perplexing, but it is essential for engineers to decode it for practical use. The “1%” likely refers to a standard measurement that may indicate a specific variable in terms of sizing or tolerance. In engineering contexts, percentages often represent material properties or the precision required for fitting components together. For instance, a 1% variation in diameter can lead to significant issues in pressure systems or fluid dynamics.

On the other hand, “202% inch” could denote a particular dimension of the end cap. It is crucial to realize that the dimensions affect not only the fit but also the functionality depending on the system it is part of. Understanding these measurements allows for enhanced compatibility, ensuring that components work seamlessly together in a larger assembly.

Material Considerations

1 2 inch end cap

When selecting an end cap, the choice of material is vital. End caps can be made from a variety of materials, including metals like stainless steel, brass, and aluminum; plastics such as PVC or polyethylene; and even composite materials for specialized applications. Each material offers different strengths, resistances to corrosion, and thermal properties, making them suited for various environments.

For example, stainless steel end caps are often used in piping systems that handle corrosive liquids or gases due to their high resistance to corrosion and mechanical strength. Conversely, plastic end caps are usually used in systems where weight and cost are more significant concerns, making them ideal for residential or less demanding industrial applications.

Applications of End Caps

End caps are used in a variety of applications, including but not limited to

1. HVAC Systems In heating, ventilation, and air conditioning systems, end caps help seal ducts and pipes, ensuring efficient airflow and preventing leaks. 2. Water Supply In plumbing systems, end caps are crucial for sealing pipes to prevent water loss and reduce contamination. 3. Industrial Manufacturing In various manufacturing settings, end caps may seal hydraulic lines and pneumatic cylinders, helping to maintain pressure and ensure smooth operation.

4. Furniture and Design In design applications, end caps can provide a polished look to the ends of metal or wooden frames, enhancing aesthetic appeal and ensuring safety.

Conclusion

The 1% 202% inch end cap may seem like a small component in the larger scheme of engineering and manufacturing, but its role is significant. Understanding the specifications, material choices, and applications of end caps can lead to greater efficiency and effectiveness in system designs. Whether you are an engineer working on complex systems or a DIY enthusiast looking to enhance your home projects, the end cap’s importance should not be overlooked. As industries evolve and new technologies emerge, the versatility and essential nature of the end cap will undoubtedly remain vital to the successful operation of many systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025