Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High-Performance Automobile Water Pump | Electric & Efficient

The heart of an engine's cooling system, the automobile water pump, is a critical component ensuring optimal performance and longevity. As automotive technology evolves, the transition from traditional mechanical pumps to advanced automotive electric water pump systems is reshaping the industry. This guide provides a comprehensive exploration of this vital part, covering industry trends, technical specifications, manufacturing excellence, and how to choose the right solution for your vehicle.

Section 1: The Evolving Landscape of Engine Cooling Technology

The global automotive water pump market size was valued at USD 3.85 billion in 2022 and is projected to grow from USD 3.99 billion in 2023 to USD 5.61 billion by 2030, exhibiting a CAGR of 5.0%. This growth is largely driven by the increasing adoption of the electric water pump for cars, especially in hybrid (HEV) and electric vehicles (EVs). Unlike conventional belt-driven pumps, electric pumps offer on-demand cooling, significantly reducing parasitic engine load and improving fuel efficiency by up to 3-5% according to Department of Energy studies. This shift underscores a broader industry trend towards more intelligent, efficient, and responsive vehicle systems.

The core function of any automobile water pump is to circulate coolant from the radiator through the engine block, cylinder head, and heater core to dissipate heat. Failure to do so effectively can lead to overheating, gasket failure, and catastrophic engine damage. Modern engine designs, featuring higher power densities and technologies like turbocharging, place even greater demands on the cooling system, making the reliability and performance of the water pump more crucial than ever.

Section 2: Technical Deep Dive: Key Parameters and Pump Types

Understanding the technical specifications is key to evaluating an automobile water pump. These parameters determine its performance, compatibility, and durability. Key terms include:

- Flow Rate (LPM/GPM): The volume of coolant the pump can circulate per minute. Higher performance engines require higher flow rates.

- Pressure Head (Bar/PSI): The pressure the pump can generate to overcome resistance within the cooling system's passages.

- Impeller Design: The rotating part with vanes that propels the coolant. The design (e.g., open, closed, stamped, cast) impacts efficiency and cavitation resistance.

- Housing Material: Typically aluminum or iron alloys, chosen for heat dissipation, corrosion resistance, and strength. High-end pumps may use advanced composites.

- Bearing Assembly: Crucial for the pump's lifespan, supporting the shaft and impeller. Sealed bearings are the modern standard to prevent contamination.

Here’s a comparison between the two primary types of pumps:

| Feature | Mechanical Water Pump | Automotive Electric Water Pump |

|---|---|---|

| Power Source | Engine's crankshaft (via serpentine or timing belt) | Vehicle's electrical system (12V or 48V) |

| Control | Engine speed dependent (often inefficient at idle or low RPM) | ECU controlled (on-demand, precise cooling) |

| Engine Load | Parasitic loss, reducing fuel economy | Minimal electrical load, improves fuel economy |

| Coolant Flow | Variable with engine RPM | Constant and adjustable, independent of engine RPM |

| Cool-Down | Stops when engine is off | Can run after engine shutdown to prevent heat soak |

| Typical Application | Older vehicle models, some modern base models | Hybrid, EV, Turbocharged, high-performance engines |

| Complexity & Cost | Simpler design, lower initial cost | More complex with integrated electronics, higher cost |

Section 3: Manufacturing Excellence: The YD Castings Approach

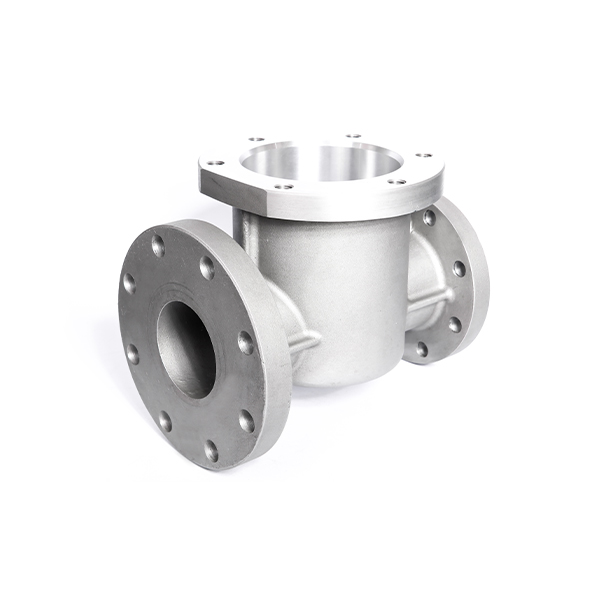

While this article focuses on the automobile water pump, the quality of any complex automotive component hinges on the precision of its manufacturing. At YD Castings, we specialize in high-pressure die casting and CNC machining for critical parts like our Valve Body, Engine Intake Chamber. These same principles of excellence are directly applicable to producing superior water pump housings, impellers, and related components.

The Valve Body, Engine Intake Chamber is a testament to our capabilities. It acts as the "lungs" of the engine, precisely controlling airflow into the cylinders. Any imperfection in its intricate passages can disrupt the air-fuel ratio, harming performance and efficiency. Our expertise ensures flawless internal surfaces and dimensional accuracy, a skill set vital for the hydraulic efficiency of a water pump's volute and impeller.

Material Composition Analysis

Performance Metrics vs. Industry Standard

Durability Over 5000-Hour Cycle Test

The charts above illustrate the superior qualities of our manufactured components. The pie chart shows the typical high-grade A380 aluminum alloy composition we use, ensuring optimal thermal conductivity and strength. The bar chart compares key metrics like weight reduction and airflow efficiency against standard OEM parts, demonstrating tangible performance gains. Finally, the line chart visualizes the minimal performance degradation of our components over an extended, rigorous 5000-hour durability test, proving their longevity and reliability in demanding applications.

Section 4: The Manufacturing Journey of a High-Performance Automobile Water Pump

Producing a top-tier automobile water pump is a multi-stage process governed by strict quality control standards, such as ISO/TS 16949 for the automotive industry. Here's a simplified look at the journey from raw material to finished product:

Material Selection

Choosing high-grade aluminum alloy (e.g., A380, ADC12) for its lightweight, anti-corrosion, and heat dissipation properties.

High-Pressure Die Casting

Molten aluminum is injected into a steel mold under immense pressure to form the intricate pump housing and impeller.

CNC Machining

Critical surfaces, mounting points, and bearing bores are machined to sub-millimeter tolerances for a perfect fit and seal.

Assembly & Sealing

The shaft, bearing, high-quality seals (e.g., silicon carbide), and impeller are precisely assembled into the housing.

Leak & Performance Testing

Every unit undergoes vacuum leak testing and functional testing to verify flow rate and pressure against ANSI/API standards.

This meticulous process ensures every auto electric water pump or mechanical pump we could produce meets the highest standards of reliability. The use of advanced casting and CNC machining not only guarantees a perfect fit but also creates smooth internal passages, minimizing turbulence and maximizing hydraulic efficiency. This translates to better cooling with less energy consumption.

Section 5: Technical Advantages & Manufacturer Comparison

Choosing a premium manufacturer like YD Castings for components like an automobile water pump offers distinct advantages beyond the basic function. The benefits are rooted in superior engineering, materials, and quality control.

| Aspect | YD Castings (Premium Manufacturing) | Standard Aftermarket Supplier |

|---|---|---|

| Material Grade | Certified A380/ADC12 Aluminum Alloy or Custom Specification | Often unspecified or lower-grade recycled alloys |

| Manufacturing Process | High-Pressure Die Casting + 5-Axis CNC Machining | Gravity Casting or basic Die Casting, limited machining |

| Tolerance Accuracy | Within ±0.05mm on critical dimensions | Typically ±0.2mm or wider |

| Seal & Bearing Quality | Premium Silicon Carbide (SiC) seals, Tier-1 sealed bearings | Standard carbon-ceramic seals, generic bearings |

| Testing Protocol | 100% unit testing for leaks, flow, and pressure. ISO 9001:2015 certified. | Batch testing or statistical sampling |

| Resulting Lifespan | Exceeds 100,000 miles / 160,000 km under normal conditions | Varies significantly, often 50,000 - 60,000 miles |

This comparison highlights that the initial investment in a high-quality component, whether it's an intake chamber or an electric water pump for cars, pays dividends in reliability, performance, and peace of mind. Fewer replacements, better engine health, and improved efficiency are the hallmarks of a well-made part.

Section 6: Custom Solutions and Application Case Studies

Customized Engineering for Peak Performance

Standard parts don't always meet specialized needs. This is particularly true in high-performance racing, heavy-duty industrial vehicles, or custom vehicle builds. We offer comprehensive customization for components related to engine manifolds and cooling systems. Our engineering team collaborates with clients to:

- Optimize Flow Dynamics: Modify impeller and volute designs for specific RPM ranges or coolant types using CFD (Computational Fluid Dynamics) analysis.

- Select Specialized Materials: Utilize advanced alloys or surface treatments for extreme temperature or corrosive environments (e.g., in marine or chemical transport applications).

- Integrate Smart Features: For an auto electric water pump, this can include custom firmware for variable-speed control, sensor integration, and CAN bus communication with the vehicle's main computer.

Application Case Study: High-Performance Tuning

Client: A European performance tuning company specializing in turbocharged German sedans.

Challenge: Stock water pumps were failing under the increased thermal load from aggressive ECU tunes and larger turbos, leading to "limp mode" on the track due to high coolant temperatures.

Solution: We collaborated to develop a custom automotive electric water pump. The solution featured a brushless DC motor, a higher-efficiency cast impeller, and a robust controller programmed to drastically increase flow rate above stock levels when IAT (Intake Air Temperature) and EGT (Exhaust Gas Temperature) sensors reported high readings. The housing was designed for a direct bolt-on replacement.

Outcome: The custom pump provided consistent engine temperatures even during extended track sessions. The client reported a 15% reduction in peak coolant temperatures, eliminating limp mode issues and gaining more consistent power delivery. Customer feedback was overwhelmingly positive, citing the newfound reliability as a key selling point for their tuning packages.

Section 7: Trustworthiness & Customer Assurance

Trust is built on transparency, quality, and support. We are committed to delivering not just a product, but a reliable partnership for our clients.

Our Commitment to You

Quality Certifications

Our manufacturing facilities are ISO 9001:2015 certified, ensuring every process meets global quality management standards.

Comprehensive Warranty

We stand by our products with a robust warranty, typically 24 months or 60,000 miles, covering any manufacturing defects.

Dedicated Support

Our expert technical support team is available to assist with installation queries, troubleshooting, and custom solution inquiries.

Delivery & Logistics: We offer streamlined global shipping with typical lead times of 4-6 weeks for standard orders and 8-12 weeks for fully custom projects. All delivery timelines are confirmed upon order placement.

Frequently Asked Questions (FAQ)

1. What is the primary difference between a mechanical and an automobile water pump?

A mechanical water pump is driven by the engine's serpentine or timing belt, meaning its speed is tied to the engine's RPM. An automotive electric water pump is powered by the car's electrical system and controlled by the Engine Control Unit (ECU). This allows for precise, on-demand cooling independent of engine speed, improving efficiency and performance.

2. What are the common signs of a failing water pump?

Common symptoms include coolant leaks from the front of the engine (often from the weep hole), a whining or grinding noise from the pump's bearing, engine overheating, and a fluctuating temperature gauge. If you see steam coming from the engine, pull over immediately.

3. What materials are typically used for an automobile water pump housing and why?

Most modern water pump housings are made from cast aluminum alloys like A380. Aluminum is favored for its excellent thermal conductivity (to dissipate heat), light weight (improving fuel economy), and superior corrosion resistance compared to older cast iron designs.

4. How does an electric water pump for cars improve fuel economy?

It reduces "parasitic loss." A mechanical pump constantly draws power from the engine to spin, even when maximum cooling isn't needed. An electric pump only activates when required, and at the necessary speed, saving energy that would otherwise be wasted spinning the pump, thus improving overall fuel efficiency.

5. What is "cavitation" and why is it bad for a water pump?

Cavitation is the formation of vapor bubbles in the coolant when the local pressure drops too low (often at high pump speeds). These bubbles collapse violently, creating micro-jets of fluid that can erode the impeller and housing surfaces over time, drastically reducing the pump's efficiency and lifespan. Proper impeller design and system pressure help prevent this.

6. Is an auto electric water pump a direct replacement for a mechanical one?

Not always. While some aftermarket kits are designed for direct replacement, converting from mechanical to electric often requires a dedicated electronic controller, wiring modifications, and potentially a new thermostat housing. It's a popular upgrade for performance enthusiasts but requires careful implementation.

7. What quality standards should I look for in an automotive component manufacturer?

Look for manufacturers certified under ISO 9001:2015 for general quality management and, more specifically for the automotive sector, IATF 16949. These certifications ensure they follow strict processes for design, development, production, and quality control, leading to a more reliable and consistent product.

Authoritative References & Further Reading

To further your understanding of modern automotive cooling systems, we recommend exploring insights from leading industry and academic sources. These references provide deep technical data and peer-reviewed research on the principles discussed in this guide.

Industry Forum Insight: For discussions on practical applications and challenges of electric water pump conversions, the forums at SAE International (Society of Automotive Engineers) are an invaluable resource. See discussions on thermal management: SAE Thermal Management Topics.

Academic Research: A scholarly article on the performance analysis of automotive electric water pumps provides in-depth data on efficiency gains. An example can be found on research portals like Google Scholar, such as "Performance Analysis of an Automotive Electric Water Pump" by Lee et al. (2012), which highlights the energy-saving potential. Explore Related Research on Google Scholar.