Mobile:+86-311-808-126-83

Email:info@ydcastings.com

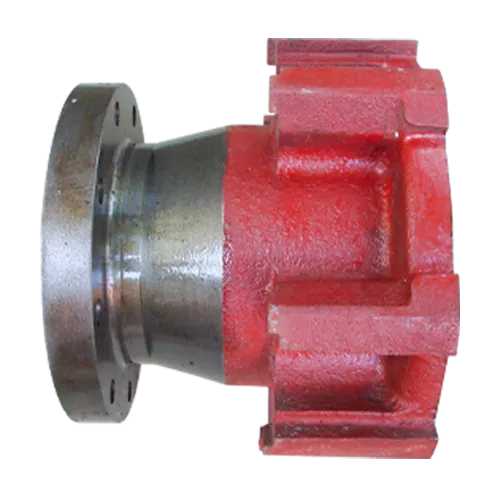

cap ends

Navigating the intricacies of products like cap ends requires an understanding rooted in experience and authority. Such understanding not only enhances user experience but also offers credibility and trustworthiness in the digital age.

Cap ends, essential in various industries, are distinct components used predominantly to secure or seal open ends of tubes, containers, or machinery parts. Their applications extend into fields like manufacturing, plumbing, and even automotive industries. While their purpose might seem simple, choosing the right cap end involves an intricate balance of several factors.

First-hand experience plays a pivotal role in understanding the nuances of cap ends. One must consider the material composition, durability, and environmental compatibility of these products. For instance, plastic cap ends are often favored for their cost-effectiveness and resistance to corrosion. However, high-strength applications might demand metal cap ends, known for their robustness and resistance to extreme temperatures or pressures.

From a professional’s perspective, selecting cap ends also involves expertise in understanding their specific requirements within industry applications. For industries requiring airtight seals, rubber or silicone cap ends might be the optimal choice. These materials ensure minimal air exchange, which is critical in preventing contamination or leakage. An expert, therefore, can effectively match the cap end material and design with the application need, creating an efficient and reliable solution.

cap ends

Authoritativeness in the realm of cap ends emerges from proven knowledge and reliability. This comes through meticulous testing and quality assurance processes. Manufacturers of cap ends often adhere to stringent industry standards, ensuring their products can withstand specific environmental conditions or operational stress. Such commitment to quality reassures users of their purchasing decisions, demonstrating an authoritative stance in the market.

Trustworthiness is another crucial factor when discussing cap ends. Vendors and manufacturers with a track record of consistency in quality and service are valued in the marketplace. Users need assurance that the cap ends they procure will meet or exceed expectations, maintain structural integrity over time, and offer a return on investment. Offering warranties, clear product specifications, and customer support further enhance trust in the product.

The decision-making process for cap ends should also take into account the sustainability factor. In today’s environmentally conscious world, opting for eco-friendly materials or manufacturers with sustainable practices can make a significant impact. This choice not only benefits the environment but can also enhance a brand's image and reputation among environmentally conscious consumers.

In conclusion, cap ends, while seemingly minor components, play a critical role in various industrial applications. Gaining expertise and authoritative insight into their selection and use can significantly benefit businesses in optimizing their operations and ensuring longevity in their infrastructure. Trust and experience, built on the pillars of quality, reliability, and sustainability, ultimately guide users towards making informed, effective decisions regarding cap ends.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025