Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Automotive Metal Casting-Hebei Yuanda Trade Co., Ltd.|High-Pressure Casting & Lightweight Solutions

Automotive metal casting and processing technology plays a pivotal role in modern vehicle manufacturing, driving advancements in efficiency, sustainability, and performance. This article explores the latest developments in casting techniques, their applications, and the contributions of companies like Hebei Yuanda Trade Co., Ltd., a leader in automotive accessory solutions. Through a detailed analysis of casting technologies, material science, and industry trends, we uncover how these innovations shape the future of the automotive sector.

Understanding Automotive Metal Casting Technologies

Automotive metal casting is a foundational process in the production of vehicle components, accounting for approximately 15-20% of all automotive parts. This process is critical for manufacturing power system components and structural elements, ensuring durability and precision. According to the National Institute of Standards and Technology (NIST), casting technologies have evolved significantly, with developed nations like the United States and Europe leading in advanced methods that prioritize quality, efficiency, and environmental sustainability.

Casting Technology: Precision and Efficiency

Casting involves shaping molten metal into molds to create complex parts. In the automotive industry, this technique is used for critical components such as engine blocks, transmission cases, and structural frames. Modern casting processes, particularly in developed countries, leverage digital technologies to optimize design and reduce waste. For instance, the casting scrap rate in these regions is maintained at 2-5%, a testament to their advanced methodologies. In contrast, China's casting industry, while producing large volumes, often focuses on lower-value "black castings" with less technical sophistication, highlighting the need for global knowledge exchange.

Die Casting: High-Performance Manufacturing

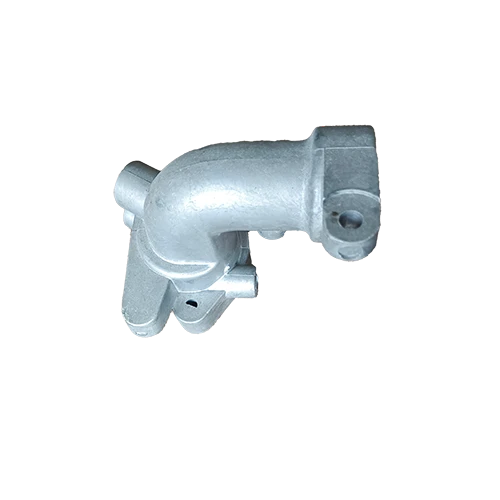

Die casting is a cornerstone of modern automotive manufacturing, utilizing high-pressure injection of molten metal into molds to produce parts with exceptional dimensional accuracy and surface quality. This method is particularly effective for creating lightweight, durable components from alloys like aluminum and zinc. The NIST emphasizes that die casting's precision reduces the need for post-processing, enhancing production efficiency and cost-effectiveness. For example, die-cast aluminum parts are widely used in engine components, improving vehicle safety and reliability.

Semi-Solid Processing: A New Frontier

Semi-solid processing represents a cutting-edge advancement in casting technology. This method involves partially solidifying metal alloys before shaping them, resulting in improved mechanical properties and reduced defects. It is especially beneficial for producing magnesium and aluminum alloy castings, which are critical for lightweight vehicle designs. According to industry reports, the global magnesium alloy die casting market is growing at a rate of 25% annually, driven by the material's low weight, high strength, and corrosion resistance. This technology addresses challenges in traditional die casting, such as porosity and thermal stress, making it ideal for high-performance automotive applications.

Integrated Design: Redefining Automotive Manufacturing

As the automotive industry prioritizes energy efficiency and cost reduction, integrated design has emerged as a key trend. By optimizing part geometry and combining multiple functions into single components, manufacturers can reduce weight and streamline production. For instance, integrated casting techniques allow for the creation of complex, lightweight parts that minimize machining operations. This approach not only lowers material costs but also enhances vehicle performance, aligning with global sustainability goals.

Technical Specifications and Material Innovations

| Parameter | Dettagli |

|---|---|

| Material | ADC-12, A380 (aluminum alloys) |

| Process | High-pressure casting |

| Weight Range | 0.5-2 kg |

| Applications | Engine manifolds, water pumps, structural components |

The use of advanced materials like ADC-12 and A380 aluminum alloys in high-pressure casting ensures excellent strength-to-weight ratios. These materials are ideal for automotive parts such as automobile water pumps and engine manifolds, which require both durability and precision. The integration of semi-solid processing further enhances these properties, enabling the production of thinner-walled components without compromising structural integrity.

Applications in Modern Automotive Engineering

Automotive casting technologies are integral to various vehicle systems, including powertrains, chassis, and cooling systems. For example, electric water pumps are critical for maintaining optimal engine temperatures in hybrid and electric vehicles. These components, often manufactured using die casting, demonstrate the industry's shift toward lightweight, high-efficiency solutions. Similarly, auto electric water pumps are designed to reduce energy consumption while ensuring reliable performance.

About Hebei Yuanda Trade Co., Ltd.

As a leading supplier of automotive accessories, Hebei Yuanda Trade Co., Ltd. specializes in high-quality casting solutions tailored to modern vehicle demands. With a focus on innovation and sustainability, the company leverages advanced technologies to produce components that meet rigorous industry standards. Their commitment to excellence is reflected in their diverse product range, including automobile water pumps and engine manifolds, which are designed for durability and efficiency.

Future Trends and Industry Outlook

The automotive industry is poised for continued innovation, with casting technologies playing a central role in achieving lightweight, eco-friendly vehicles. As highlighted by NIST, the adoption of digital twins and AI-driven design tools will further enhance casting processes, reducing waste and improving precision. Additionally, the growing demand for electric vehicles (EVs) is driving the need for specialized components, such as electric water pumps, which are essential for thermal management in EV powertrains.

Conclusion

Automotive metal casting and processing technologies are at the forefront of the industry's evolution, enabling manufacturers to meet the challenges of sustainability, performance, and cost-efficiency. Through advancements like die casting, semi-solid processing, and integrated design, companies like Hebei Yuanda Trade Co., Ltd. are setting new benchmarks for quality and innovation. As the sector continues to embrace digital transformation, the future of automotive manufacturing looks increasingly promising.

References

National Institute of Standards and Technology (NIST). (2023). Manufacturing and Materials Standards. Retrieved from https://www.nist.gov/

Hebei Yuanda Trade Co., Ltd.. (2023). Automotive Accessories. Retrieved from https://www.ydcastings.com/automobile-accessories.html

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025