Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Automotive Metal Casting-Hebei Yuanda|Die Casting&Semi-Solid Processing

In the ever-evolving automotive industry, automobile accessories play a pivotal role in enhancing vehicle performance, safety, and efficiency. The advancements in metal casting and processing technologies have revolutionized the production of automotive parts, enabling manufacturers to meet the growing demands for lightweight, durable, and high-performance components. This article explores the latest developments in automotive metal casting, including casting technology, die casting, semi-solid processing, and integrated design, while highlighting the contributions of Hebei Yuanda Trade Co., Ltd., a leading provider of automotive solutions.

Overview of Automotive Metal Casting Technologies

The production of automotive parts relies heavily on metal casting and processing technologies, which account for approximately 15% to 20% of all automotive components. These processes are critical for manufacturing power system key components and structural parts, ensuring the reliability and performance of vehicles. Developed countries such as the United States and European nations have advanced casting technologies that prioritize high-quality output, efficient production, and minimal environmental impact. For instance, the use of digital technology in casting process design has reduced the scrap rate to 2% to 5%, showcasing the efficiency of modern techniques.

Casting Technology: Foundation of Automotive Manufacturing

Casting is a fundamental process in automotive manufacturing, particularly for producing critical components such as engine blocks and transmission housings. The technology involves pouring molten metal into molds to create complex shapes with high precision. In developed countries, casting technology has evolved to incorporate advanced digital tools that optimize design and reduce waste. This has led to improved product quality and a significant reduction in environmental pollution. In contrast, China's casting industry, while producing large volumes, often faces challenges in terms of technical sophistication and value addition.

One of the key advantages of modern casting technology is its ability to produce parts with intricate geometries, which are essential for modern vehicle designs. The integration of computer-aided design (CAD) and simulation tools allows manufacturers to predict potential defects and refine the casting process before production begins. This not only enhances the quality of the final product but also reduces the need for costly rework.

Die Casting: Precision and Efficiency in Automotive Production

Die casting is a vital process in modern automotive manufacturing, where molten metal is injected into a mold under high pressure to create precise parts. This method is particularly effective for producing components with tight dimensional tolerances and excellent surface finish. The use of various metal alloys, such as aluminum and zinc, ensures that the parts are not only strong but also lightweight, contributing to the overall efficiency of the vehicle.

The advantages of die casting extend beyond just the physical properties of the parts. By reducing the need for extensive machining, die casting significantly lowers production costs and enhances manufacturing efficiency. This is crucial for automotive companies aiming to meet the increasing demand for vehicles while maintaining high standards of quality and performance.

Semi-Solid Processing: A New Frontier in Automotive Casting

Semi-solid processing technology represents a significant advancement in the production of automotive parts, particularly for magnesium and aluminum alloys. This technique addresses the challenges associated with traditional die casting, such as poor mechanical properties and high costs. By allowing the casting of parts with thinner walls (1-1.5mm) and reduced mold slope (1°-2°), semi-solid processing enables the creation of lighter, more durable components.

The application of magnesium alloys in automotive manufacturing is gaining traction due to their lightweight and high strength-to-weight ratio. According to the National Institute of Standards and Technology (NIST), the use of advanced materials like magnesium alloys can significantly reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. This aligns with the global push towards sustainable and environmentally friendly automotive solutions.

Integrated Design: Enhancing Performance and Reducing Costs

As the automotive industry continues to prioritize energy efficiency and cost reduction, integrated design has emerged as a critical trend in casting technology. This approach involves optimizing the design and structure of parts to minimize weight and eliminate unnecessary machining processes. By creating single-piece components, manufacturers can achieve significant reductions in both material usage and production costs.

Integrated design not only enhances the performance of automotive parts but also contributes to the overall sustainability of the industry. For example, the use of integrated casting for engine manifolds and other components allows for improved airflow and reduced emissions, aligning with stringent environmental regulations. This innovative approach is essential for meeting the demands of modern vehicles, which require both high performance and eco-friendly solutions.

Product Specifications and Applications

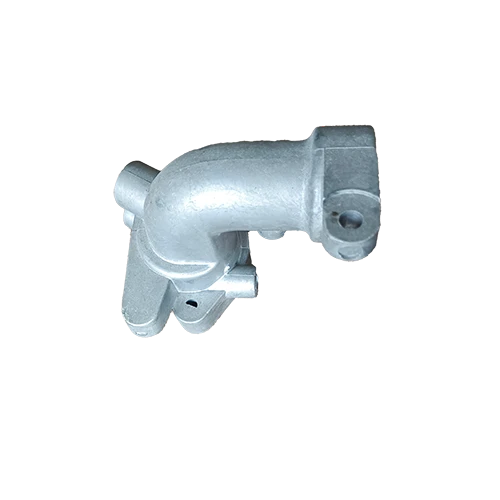

IL automobile accessories produced by Hebei Yuanda Trade Co., Ltd. are designed to meet the rigorous demands of the automotive industry. The following table provides an overview of the key specifications of these products:

| Material | Process | Specification |

|---|---|---|

| ADC-12, A380 | High pressure casting | 0.5-2kg |

These specifications highlight the versatility and precision of the products, which are suitable for a wide range of automotive applications. The use of high-pressure casting ensures that the parts are both durable and lightweight, making them ideal for components such as automotive electric water pumps and engine manifolds. The ability to produce parts with specific weight ranges allows manufacturers to tailor their products to meet the unique requirements of different vehicle models.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a prominent player in the automotive industry, specializing in the production of high-quality automobile accessories. With a commitment to innovation and excellence, the company has established itself as a reliable supplier of automotive parts to both domestic and international markets. Their expertise in metal casting and processing technologies enables them to deliver products that meet the highest standards of quality and performance.

The company's focus on advanced manufacturing techniques, such as die casting and semi-solid processing, underscores its dedication to staying at the forefront of industry trends. By investing in research and development, Hebei Yuanda Trade Co., Ltd. continues to enhance its product offerings and meet the evolving needs of the automotive sector. This commitment to innovation is reflected in the company's ability to provide customized solutions that address the specific challenges faced by manufacturers.

Conclusion

The advancements in metal casting and processing technologies have significantly transformed the automotive industry, enabling the production of lighter, more durable, and more efficient components. From casting technology to die casting, semi-solid processing, and integrated design, each innovation contributes to the overall performance and sustainability of vehicles. Hebei Yuanda Trade Co., Ltd. exemplifies the importance of these technologies, offering high-quality automobile accessories that meet the demands of modern automotive manufacturing.

As the industry continues to evolve, the role of advanced casting technologies will become even more critical. By embracing these innovations, manufacturers can not only enhance their products but also contribute to a more sustainable future. The collaboration between companies like Hebei Yuanda Trade Co., Ltd. and the broader automotive community will be essential in driving the next wave of advancements in this dynamic field.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

2. Hebei Yuanda Trade Co., Ltd. (n.d.). Automobile Accessories. Retrieved from https://www.ydcastings.com/automobile-accessories.html

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025

Automotive Metal Casting-Hebei Yuanda|Die Casting&Semi-Solid Processing

In the ever-evolving automotive industry, automobile accessories play a pivotal role in enhancing vehicle performance, safety, and efficiency. The advancements in metal casting and processing technologies have revolutionized the production of automotive parts, enabling manufacturers to meet the growing demands for lightweight, durable, and high-performance components. This article explores the latest developments in automotive metal casting, including casting technology, die casting, semi-solid processing, and integrated design, while highlighting the contributions of Hebei Yuanda Trade Co., Ltd., a leading provider of automotive solutions.

Overview of Automotive Metal Casting Technologies

The production of automotive parts relies heavily on metal casting and processing technologies, which account for approximately 15% to 20% of all automotive components. These processes are critical for manufacturing power system key components and structural parts, ensuring the reliability and performance of vehicles. Developed countries such as the United States and European nations have advanced casting technologies that prioritize high-quality output, efficient production, and minimal environmental impact. For instance, the use of digital technology in casting process design has reduced the scrap rate to 2% to 5%, showcasing the efficiency of modern techniques.

Casting Technology: Foundation of Automotive Manufacturing

Casting is a fundamental process in automotive manufacturing, particularly for producing critical components such as engine blocks and transmission housings. The technology involves pouring molten metal into molds to create complex shapes with high precision. In developed countries, casting technology has evolved to incorporate advanced digital tools that optimize design and reduce waste. This has led to improved product quality and a significant reduction in environmental pollution. In contrast, China's casting industry, while producing large volumes, often faces challenges in terms of technical sophistication and value addition.

One of the key advantages of modern casting technology is its ability to produce parts with intricate geometries, which are essential for modern vehicle designs. The integration of computer-aided design (CAD) and simulation tools allows manufacturers to predict potential defects and refine the casting process before production begins. This not only enhances the quality of the final product but also reduces the need for costly rework.

Die Casting: Precision and Efficiency in Automotive Production

Die casting is a vital process in modern automotive manufacturing, where molten metal is injected into a mold under high pressure to create precise parts. This method is particularly effective for producing components with tight dimensional tolerances and excellent surface finish. The use of various metal alloys, such as aluminum and zinc, ensures that the parts are not only strong but also lightweight, contributing to the overall efficiency of the vehicle.

The advantages of die casting extend beyond just the physical properties of the parts. By reducing the need for extensive machining, die casting significantly lowers production costs and enhances manufacturing efficiency. This is crucial for automotive companies aiming to meet the increasing demand for vehicles while maintaining high standards of quality and performance.

Semi-Solid Processing: A New Frontier in Automotive Casting

Semi-solid processing technology represents a significant advancement in the production of automotive parts, particularly for magnesium and aluminum alloys. This technique addresses the challenges associated with traditional die casting, such as poor mechanical properties and high costs. By allowing the casting of parts with thinner walls (1-1.5mm) and reduced mold slope (1°-2°), semi-solid processing enables the creation of lighter, more durable components.

The application of magnesium alloys in automotive manufacturing is gaining traction due to their lightweight and high strength-to-weight ratio. According to the National Institute of Standards and Technology (NIST), the use of advanced materials like magnesium alloys can significantly reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. This aligns with the global push towards sustainable and environmentally friendly automotive solutions.

Integrated Design: Enhancing Performance and Reducing Costs

As the automotive industry continues to prioritize energy efficiency and cost reduction, integrated design has emerged as a critical trend in casting technology. This approach involves optimizing the design and structure of parts to minimize weight and eliminate unnecessary machining processes. By creating single-piece components, manufacturers can achieve significant reductions in both material usage and production costs.

Integrated design not only enhances the performance of automotive parts but also contributes to the overall sustainability of the industry. For example, the use of integrated casting for engine manifolds and other components allows for improved airflow and reduced emissions, aligning with stringent environmental regulations. This innovative approach is essential for meeting the demands of modern vehicles, which require both high performance and eco-friendly solutions.

Product Specifications and Applications

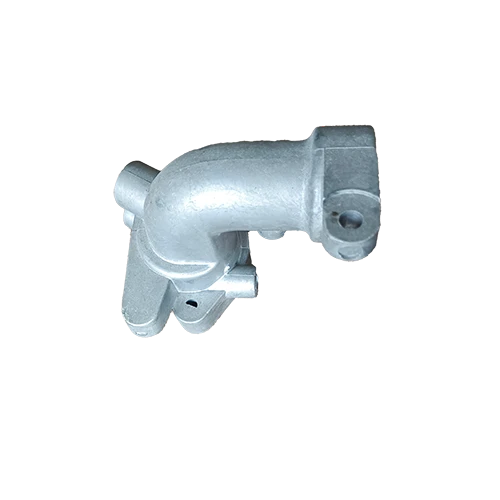

IL automobile accessories produced by Hebei Yuanda Trade Co., Ltd. are designed to meet the rigorous demands of the automotive industry. The following table provides an overview of the key specifications of these products:

| Material | Process | Specification |

|---|---|---|

| ADC-12, A380 | High pressure casting | 0.5-2kg |

These specifications highlight the versatility and precision of the products, which are suitable for a wide range of automotive applications. The use of high-pressure casting ensures that the parts are both durable and lightweight, making them ideal for components such as automotive electric water pumps and engine manifolds. The ability to produce parts with specific weight ranges allows manufacturers to tailor their products to meet the unique requirements of different vehicle models.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a prominent player in the automotive industry, specializing in the production of high-quality automobile accessories. With a commitment to innovation and excellence, the company has established itself as a reliable supplier of automotive parts to both domestic and international markets. Their expertise in metal casting and processing technologies enables them to deliver products that meet the highest standards of quality and performance.

The company's focus on advanced manufacturing techniques, such as die casting and semi-solid processing, underscores its dedication to staying at the forefront of industry trends. By investing in research and development, Hebei Yuanda Trade Co., Ltd. continues to enhance its product offerings and meet the evolving needs of the automotive sector. This commitment to innovation is reflected in the company's ability to provide customized solutions that address the specific challenges faced by manufacturers.

Conclusion

The advancements in metal casting and processing technologies have significantly transformed the automotive industry, enabling the production of lighter, more durable, and more efficient components. From casting technology to die casting, semi-solid processing, and integrated design, each innovation contributes to the overall performance and sustainability of vehicles. Hebei Yuanda Trade Co., Ltd. exemplifies the importance of these technologies, offering high-quality automobile accessories that meet the demands of modern automotive manufacturing.

As the industry continues to evolve, the role of advanced casting technologies will become even more critical. By embracing these innovations, manufacturers can not only enhance their products but also contribute to a more sustainable future. The collaboration between companies like Hebei Yuanda Trade Co., Ltd. and the broader automotive community will be essential in driving the next wave of advancements in this dynamic field.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

2. Hebei Yuanda Trade Co., Ltd. (n.d.). Automobile Accessories. Retrieved from https://www.ydcastings.com/automobile-accessories.html

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025