Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Advanced Automotive Metal Casting Technologies - Hebei Yuanda Trade Co.|Precision Die Casting,Semi-Solid Processing

Understanding Automotive Metal Casting Technologies

Automotive metal casting is a critical process in vehicle production, accounting for approximately 15-20% of all automotive parts. This technology is primarily used for manufacturing power system components and structural parts. Advanced casting techniques have significantly improved product quality, production efficiency, and environmental sustainability.

According to the National Institute of Standards and Technology (NIST), modern casting technologies leverage digital tools to enhance process design, reducing scrap rates to 2-5% in developed countries. In contrast, China's automotive casting industry still faces challenges in achieving comparable technical standards, despite its large output volume.

Casting Technology Innovations

Casting remains a foundational process in automotive manufacturing. The use of digital technology has transformed traditional methods, enabling precise control over material properties and reducing waste. Key advancements include:

- Improved mold design through computer-aided engineering (CAE)

- Enhanced material flow analysis for optimal casting

- Real-time monitoring systems for quality control

Die Casting Process: Precision and Efficiency

Die casting plays a pivotal role in modern automotive manufacturing. This high-pressure process involves injecting molten metal into a mold to create precise components. The technology offers several advantages:

- High dimensional accuracy and surface finish

- Ability to produce complex geometries

- Use of lightweight alloys like aluminum and zinc

According to NIST, die casting processes have seen significant improvements in energy efficiency and environmental impact reduction. The integration of automation and advanced materials has further enhanced the reliability and safety of automotive components.

Read More About auto electric water pump

Semi-Solid Processing: A New Frontier

Semi-solid processing technology has emerged as a game-changer in the production of magnesium and aluminum alloy castings. This method addresses traditional challenges in die casting, such as porosity and cost inefficiencies. Key benefits include:

- Thinner casting walls (1-1.5mm)

- Improved mechanical properties

- Enhanced formability and dimensional stability

IL NIST highlights that semi-solid processing is gaining traction in the automotive sector due to its ability to produce lightweight components without compromising strength. This technology is particularly valuable for applications requiring high thermal and corrosion resistance.

Read More About electric water pump for car

Integrated Design: The Future of Automotive Manufacturing

Integrated design is becoming a cornerstone of modern automotive engineering. By optimizing part structures and reducing machining requirements, this approach contributes to lighter, more efficient vehicles. Key aspects include:

- Weight reduction through advanced material utilization

- Streamlined production processes

- Enhanced vehicle performance and safety

According to NIST, integrated design methodologies are critical for achieving the industry's sustainability goals. These innovations align with global efforts to reduce carbon footprints and improve fuel efficiency.

Read More About automotive electric water pump

Technical Specifications of Automotive Components

| Parameter | Dettagli |

|---|---|

| Material | ADC-12, A380 |

| Process | High Pressure Casting |

| Weight Range | 0.5-2kg |

| Surface Finish | High Precision (±0.05mm) |

| Applications | Engine Components, Transmission Parts, Structural Elements |

Applications in Modern Automotive Systems

The advancements in casting technologies have enabled the production of components that meet the rigorous demands of modern vehicles. Key applications include:

- Automotive Electric Water Pumps: Essential for cooling systems, these pumps offer high efficiency and durability.

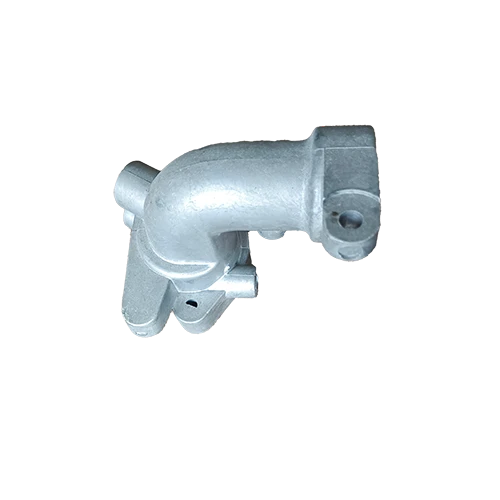

- Engine Manifolds: Critical for air and fuel distribution, these components benefit from precise casting techniques.

- Transmission Components: High-strength alloys ensure reliability under demanding conditions.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer specializing in automotive casting solutions. With a focus on innovation and quality, the company has established itself as a trusted partner in the automotive industry. Their commitment to advanced technologies and sustainable practices positions them at the forefront of automotive component manufacturing.

For more information about their products and services, visit Hebei Yuanda Trade Co., Ltd..

Conclusion

The continuous evolution of metal casting and processing technologies is reshaping the automotive industry. From precision die casting to semi-solid processing, these innovations are driving the development of lighter, more efficient, and environmentally friendly vehicles. As companies like Hebei Yuanda Trade Co., Ltd. push the boundaries of what's possible, the future of automotive manufacturing looks brighter than ever.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025

Advanced Automotive Metal Casting Technologies - Hebei Yuanda Trade Co.|Precision Die Casting,Semi-Solid Processing

In the ever-evolving automotive industry, the demand for lightweight, high-performance components has driven significant advancements in metal casting and processing technologies. This article explores the latest innovations in automotive parts manufacturing, focusing on casting techniques, die casting processes, semi-solid processing, and integrated design methodologies. We also highlight the role of Hebei Yuanda Trade Co., Ltd. in delivering superior automotive solutions.

Understanding Automotive Metal Casting Technologies

Automotive metal casting is a critical process in vehicle production, accounting for approximately 15-20% of all automotive parts. This technology is primarily used for manufacturing power system components and structural parts. Advanced casting techniques have significantly improved product quality, production efficiency, and environmental sustainability.

According to the National Institute of Standards and Technology (NIST), modern casting technologies leverage digital tools to enhance process design, reducing scrap rates to 2-5% in developed countries. In contrast, China's automotive casting industry still faces challenges in achieving comparable technical standards, despite its large output volume.

Casting Technology Innovations

Casting remains a foundational process in automotive manufacturing. The use of digital technology has transformed traditional methods, enabling precise control over material properties and reducing waste. Key advancements include:

- Improved mold design through computer-aided engineering (CAE)

- Enhanced material flow analysis for optimal casting

- Real-time monitoring systems for quality control

Die Casting Process: Precision and Efficiency

Die casting plays a pivotal role in modern automotive manufacturing. This high-pressure process involves injecting molten metal into a mold to create precise components. The technology offers several advantages:

- High dimensional accuracy and surface finish

- Ability to produce complex geometries

- Use of lightweight alloys like aluminum and zinc

According to NIST, die casting processes have seen significant improvements in energy efficiency and environmental impact reduction. The integration of automation and advanced materials has further enhanced the reliability and safety of automotive components.

Read More About auto electric water pump

Semi-Solid Processing: A New Frontier

Semi-solid processing technology has emerged as a game-changer in the production of magnesium and aluminum alloy castings. This method addresses traditional challenges in die casting, such as porosity and cost inefficiencies. Key benefits include:

- Thinner casting walls (1-1.5mm)

- Improved mechanical properties

- Enhanced formability and dimensional stability

IL NIST highlights that semi-solid processing is gaining traction in the automotive sector due to its ability to produce lightweight components without compromising strength. This technology is particularly valuable for applications requiring high thermal and corrosion resistance.

Read More About electric water pump for car

Integrated Design: The Future of Automotive Manufacturing

Integrated design is becoming a cornerstone of modern automotive engineering. By optimizing part structures and reducing machining requirements, this approach contributes to lighter, more efficient vehicles. Key aspects include:

- Weight reduction through advanced material utilization

- Streamlined production processes

- Enhanced vehicle performance and safety

According to NIST, integrated design methodologies are critical for achieving the industry's sustainability goals. These innovations align with global efforts to reduce carbon footprints and improve fuel efficiency.

Read More About automotive electric water pump

Technical Specifications of Automotive Components

| Parameter | Dettagli |

|---|---|

| Material | ADC-12, A380 |

| Process | High Pressure Casting |

| Weight Range | 0.5-2kg |

| Surface Finish | High Precision (±0.05mm) |

| Applications | Engine Components, Transmission Parts, Structural Elements |

Applications in Modern Automotive Systems

The advancements in casting technologies have enabled the production of components that meet the rigorous demands of modern vehicles. Key applications include:

- Automotive Electric Water Pumps: Essential for cooling systems, these pumps offer high efficiency and durability.

- Engine Manifolds: Critical for air and fuel distribution, these components benefit from precise casting techniques.

- Transmission Components: High-strength alloys ensure reliability under demanding conditions.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer specializing in automotive casting solutions. With a focus on innovation and quality, the company has established itself as a trusted partner in the automotive industry. Their commitment to advanced technologies and sustainable practices positions them at the forefront of automotive component manufacturing.

For more information about their products and services, visit Hebei Yuanda Trade Co., Ltd..

Conclusion

The continuous evolution of metal casting and processing technologies is reshaping the automotive industry. From precision die casting to semi-solid processing, these innovations are driving the development of lighter, more efficient, and environmentally friendly vehicles. As companies like Hebei Yuanda Trade Co., Ltd. push the boundaries of what's possible, the future of automotive manufacturing looks brighter than ever.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025