Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Advanced Automotive Metal Casting - Hebei Yuanda Trade Co., Ltd.|Die Casting&Semi-Solid Processing

Introduction to Automotive Metal Casting and Processing

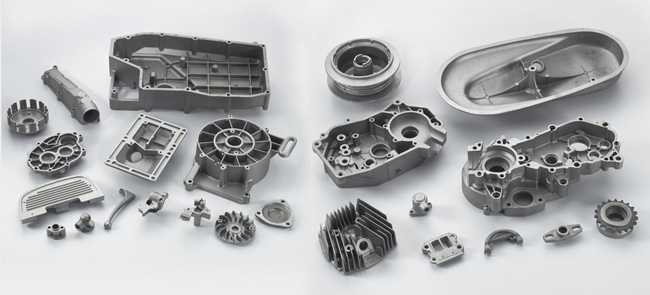

The automotive industry relies heavily on precision engineering and advanced manufacturing technologies to produce high-quality components. Metal casting and processing are critical processes in automotive manufacturing, accounting for approximately 15% to 20% of all automotive parts. These technologies ensure the production of durable, lightweight, and high-performance components that meet the demands of modern vehicles. Automobile accessories such as engine manifolds, water pumps, and structural components are manufactured using cutting-edge techniques that enhance efficiency and reduce environmental impact.

Key Technologies in Automotive Metal Casting

1. Casting Technology

Casting is a foundational process in automotive manufacturing, particularly for power system components and structural parts. In developed countries like the United States and Europe, casting technologies have advanced significantly, resulting in high-quality products with minimal environmental pollution. These regions utilize digital technologies to optimize casting processes, achieving a scrap rate of 2% to 5%. In contrast, China's automotive casting industry, while producing large volumes, often lags in technical sophistication, with many parts being low-value black castings. Automotive electric water pump components, for instance, benefit from these advanced casting methods to ensure precision and durability.

2. Die Casting Process

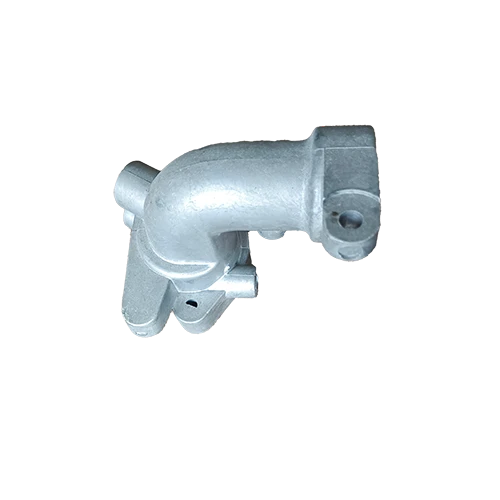

Die casting is a high-pressure process that involves injecting molten metal into a mold to create precise, complex shapes. This method is widely used for producing components like engine manifolds and electric water pump for car. Die casting allows for tight dimensional tolerances and excellent surface finishes, which are essential for ensuring the stability and performance of automotive systems. The use of aluminum and zinc alloys in die casting enhances the strength and durability of parts, contributing to the safety and reliability of vehicles.

3. Semi-Solid Processing Technology

Semi-solid processing is a modern technique that combines the advantages of casting and forging. It is particularly effective for producing magnesium and aluminum alloy castings with thin walls (1-1.5 mm) and precise geometries. This technology addresses the challenges of traditional die casting, such as poor performance and high costs, making it ideal for lightweight automotive components. Auto electric water pump parts, for example, benefit from semi-solid processing to achieve superior strength and corrosion resistance.

4. Integrated Design

Integrated design is a trend in automotive manufacturing, focusing on reducing part weight and production costs through structural optimization. By combining multiple components into a single casting, manufacturers can minimize machining processes and enhance performance. This approach aligns with the industry's goals of energy efficiency and sustainability. Automobile water pump components are often designed with integrated features to improve functionality and reduce overall vehicle weight.

Applications of Advanced Casting Technologies

The advancements in metal casting and processing technologies have enabled the production of a wide range of automotive components. Key applications include:

- Engine manifolds: These components distribute air or fuel to the engine's cylinders, requiring precise casting to ensure optimal performance.

- Electric water pumps: Essential for cooling systems, these pumps rely on high-precision die casting to maintain efficiency and reliability.

- Structural components: Lightweight and durable materials are critical for improving vehicle safety and fuel efficiency.

These technologies not only enhance the performance of individual parts but also contribute to the overall efficiency and sustainability of automotive manufacturing.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer specializing in automotive metal casting and processing. With a focus on innovation and quality, the company provides a wide range of automotive accessories, including automotive electric water pumps and engine manifolds. Their commitment to advanced technologies ensures that their products meet the stringent requirements of the automotive industry. The company's expertise in high-pressure casting and semi-solid processing allows them to produce components with exceptional precision and durability.

Product Specifications

| Material | ADC-12, A380 |

|---|---|

| Process | High Pressure Casting |

| Specification | 0.5-2kg |

Future Trends and Industry Outlook

The automotive industry is continuously evolving, driven by the need for lighter, more efficient, and environmentally friendly vehicles. Future trends in metal casting and processing include the adoption of digital twins, AI-driven optimization, and sustainable materials. According to research from the National Institute of Standards and Technology (NIST), advancements in these areas will play a crucial role in shaping the next generation of automotive components. NIST has emphasized the importance of standardized testing and measurement in ensuring the quality and reliability of new technologies.

Conclusion

Advanced metal casting and processing technologies are essential for the automotive industry's continued growth and innovation. By leveraging cutting-edge techniques such as die casting, semi-solid processing, and integrated design, manufacturers can produce high-performance, lightweight components that meet modern demands. Hebei Yuanda Trade Co., Ltd. exemplifies the commitment to excellence in this field, offering a wide range of automotive accessories that combine precision, durability, and sustainability. As the industry moves toward a more efficient and eco-friendly future, these technologies will remain at the forefront of automotive manufacturing.

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025

Advanced Automotive Metal Casting - Hebei Yuanda Trade Co., Ltd.|Die Casting&Semi-Solid Processing

Introduction to Automotive Metal Casting and Processing

The automotive industry relies heavily on precision engineering and advanced manufacturing technologies to produce high-quality components. Metal casting and processing are critical processes in automotive manufacturing, accounting for approximately 15% to 20% of all automotive parts. These technologies ensure the production of durable, lightweight, and high-performance components that meet the demands of modern vehicles. Automobile accessories such as engine manifolds, water pumps, and structural components are manufactured using cutting-edge techniques that enhance efficiency and reduce environmental impact.

Key Technologies in Automotive Metal Casting

1. Casting Technology

Casting is a foundational process in automotive manufacturing, particularly for power system components and structural parts. In developed countries like the United States and Europe, casting technologies have advanced significantly, resulting in high-quality products with minimal environmental pollution. These regions utilize digital technologies to optimize casting processes, achieving a scrap rate of 2% to 5%. In contrast, China's automotive casting industry, while producing large volumes, often lags in technical sophistication, with many parts being low-value black castings. Automotive electric water pump components, for instance, benefit from these advanced casting methods to ensure precision and durability.

2. Die Casting Process

Die casting is a high-pressure process that involves injecting molten metal into a mold to create precise, complex shapes. This method is widely used for producing components like engine manifolds and electric water pump for car. Die casting allows for tight dimensional tolerances and excellent surface finishes, which are essential for ensuring the stability and performance of automotive systems. The use of aluminum and zinc alloys in die casting enhances the strength and durability of parts, contributing to the safety and reliability of vehicles.

3. Semi-Solid Processing Technology

Semi-solid processing is a modern technique that combines the advantages of casting and forging. It is particularly effective for producing magnesium and aluminum alloy castings with thin walls (1-1.5 mm) and precise geometries. This technology addresses the challenges of traditional die casting, such as poor performance and high costs, making it ideal for lightweight automotive components. Auto electric water pump parts, for example, benefit from semi-solid processing to achieve superior strength and corrosion resistance.

4. Integrated Design

Integrated design is a trend in automotive manufacturing, focusing on reducing part weight and production costs through structural optimization. By combining multiple components into a single casting, manufacturers can minimize machining processes and enhance performance. This approach aligns with the industry's goals of energy efficiency and sustainability. Automobile water pump components are often designed with integrated features to improve functionality and reduce overall vehicle weight.

Applications of Advanced Casting Technologies

The advancements in metal casting and processing technologies have enabled the production of a wide range of automotive components. Key applications include:

- Engine manifolds: These components distribute air or fuel to the engine's cylinders, requiring precise casting to ensure optimal performance.

- Electric water pumps: Essential for cooling systems, these pumps rely on high-precision die casting to maintain efficiency and reliability.

- Structural components: Lightweight and durable materials are critical for improving vehicle safety and fuel efficiency.

These technologies not only enhance the performance of individual parts but also contribute to the overall efficiency and sustainability of automotive manufacturing.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer specializing in automotive metal casting and processing. With a focus on innovation and quality, the company provides a wide range of automotive accessories, including automotive electric water pumps and engine manifolds. Their commitment to advanced technologies ensures that their products meet the stringent requirements of the automotive industry. The company's expertise in high-pressure casting and semi-solid processing allows them to produce components with exceptional precision and durability.

Product Specifications

| Material | ADC-12, A380 |

|---|---|

| Process | High Pressure Casting |

| Specification | 0.5-2kg |

Future Trends and Industry Outlook

The automotive industry is continuously evolving, driven by the need for lighter, more efficient, and environmentally friendly vehicles. Future trends in metal casting and processing include the adoption of digital twins, AI-driven optimization, and sustainable materials. According to research from the National Institute of Standards and Technology (NIST), advancements in these areas will play a crucial role in shaping the next generation of automotive components. NIST has emphasized the importance of standardized testing and measurement in ensuring the quality and reliability of new technologies.

Conclusion

Advanced metal casting and processing technologies are essential for the automotive industry's continued growth and innovation. By leveraging cutting-edge techniques such as die casting, semi-solid processing, and integrated design, manufacturers can produce high-performance, lightweight components that meet modern demands. Hebei Yuanda Trade Co., Ltd. exemplifies the commitment to excellence in this field, offering a wide range of automotive accessories that combine precision, durability, and sustainability. As the industry moves toward a more efficient and eco-friendly future, these technologies will remain at the forefront of automotive manufacturing.

-

Materials Used in Manufacturing Cap End Pipe FittingsNotiziaNov.24,2025

-

Material Properties of CF8M CastingNotiziaNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNotiziaNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNotiziaNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNotiziaNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNotiziaNov.21,2025