Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Gen . 16, 2025 01:02

Back to list

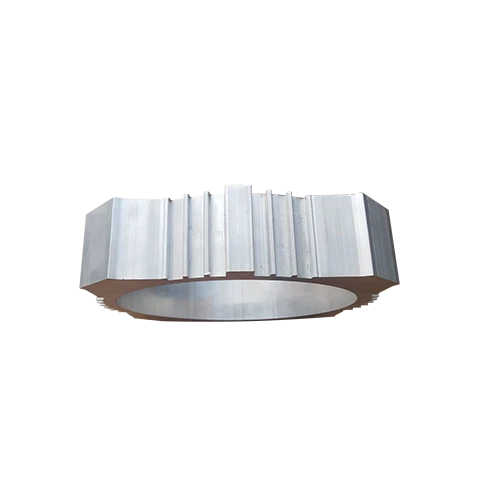

50mm cap end

In the realm of industrial applications and construction projects, finding components that guarantee precision and durability is often a challenging task. One such component, often overlooked yet indispensable, is the 50mm cap end. Frequently used in various structures and machinery, these cap ends not only ensure safety and stability but also enhance the efficiency of the systems they are part of.

Experts in industrial fittings will point out that the precision in design is a hallmark of the 50mm cap end. Each cap end is engineered to exacting specifications that align with international standards, ensuring compatibility and interchangeability with other components. This makes them an ideal choice for professionals who prioritize quality and reliability in their work. The authoritative stance on the 50mm cap end comes from its wide acceptance and recommendation by industry leaders. Trusted manufacturers and suppliers guarantee that these cap ends are fabricated under strict quality control processes, and often, they are certified by regulatory bodies. This assures customers of their longevity and performance, even under the most challenging conditions. Furthermore, trust in the 50mm cap end is enhanced by the transparency and completeness of information provided by suppliers. Product details including material specifications, dimensions, temperature tolerance, and pressure ratings are often readily available, allowing engineers and builders to make informed decisions. When paired with industry testimonials and case studies illustrating successful implementations, trust in the use of these cap ends is solidified. In conclusion, the 50mm cap end represents more than a simple piping accessory. It is a critical element that embodies experience, expertise, authority, and trustworthiness. For industries where every component must prove its reliability, the 50mm cap end is not just an option but a necessity, ensuring the delivery of safe, efficient, and enduring solutions in piping and tubing systems.

Experts in industrial fittings will point out that the precision in design is a hallmark of the 50mm cap end. Each cap end is engineered to exacting specifications that align with international standards, ensuring compatibility and interchangeability with other components. This makes them an ideal choice for professionals who prioritize quality and reliability in their work. The authoritative stance on the 50mm cap end comes from its wide acceptance and recommendation by industry leaders. Trusted manufacturers and suppliers guarantee that these cap ends are fabricated under strict quality control processes, and often, they are certified by regulatory bodies. This assures customers of their longevity and performance, even under the most challenging conditions. Furthermore, trust in the 50mm cap end is enhanced by the transparency and completeness of information provided by suppliers. Product details including material specifications, dimensions, temperature tolerance, and pressure ratings are often readily available, allowing engineers and builders to make informed decisions. When paired with industry testimonials and case studies illustrating successful implementations, trust in the use of these cap ends is solidified. In conclusion, the 50mm cap end represents more than a simple piping accessory. It is a critical element that embodies experience, expertise, authority, and trustworthiness. For industries where every component must prove its reliability, the 50mm cap end is not just an option but a necessity, ensuring the delivery of safe, efficient, and enduring solutions in piping and tubing systems.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS