Mobile:+86-311-808-126-83

Email:info@ydcastings.com

types of casting

Types of Casting Understanding the Various Methods in Metalworking

Casting is an ancient manufacturing process that involves pouring molten metal into a mold to create solid parts. This method has evolved over thousands of years and has become fundamental in modern engineering and manufacturing, enabling the production of complex shapes that would be difficult or impossible to achieve through other means. There are several types of casting techniques, each suitable for different applications and materials. This article explores the most common types of casting and their unique characteristics.

1. Sand Casting

Sand casting is one of the oldest and most widely used casting methods. It involves creating a mold from a mixture of sand, clay, and water. The sand is packed around a pattern, which is a replica of the desired object. Once the pattern is removed, molten metal is poured into the cavity left behind. Sand casting is particularly valued for its versatility; it can accommodate large components and is used in industries ranging from automotive to aerospace. However, the surface finish may not be as smooth as other methods, which can require further machining.

2

. Investment CastingInvestment casting, also known as lost-wax casting, is a precision casting method that allows for intricate designs and tighter tolerances. In this process, a wax pattern is coated in a ceramic shell, which is then heated to remove the wax, leaving a cavity for molten metal. This technique is best suited for small to medium-sized components and is commonly used in the production of jewelry, medical devices, and turbine blades. Investment casting offers excellent surface finish and detail, but it can be more expensive and time-consuming compared to other casting methods.

3. Die Casting

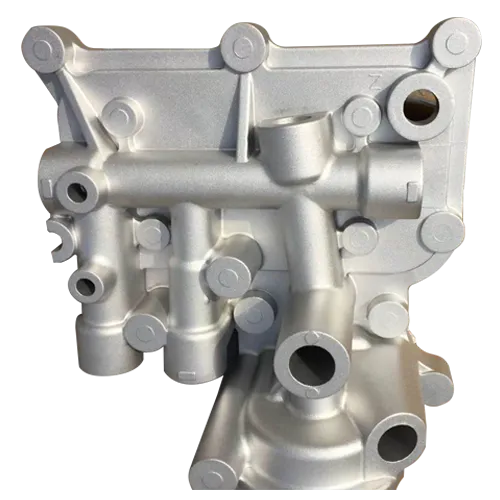

types of casting

Die casting is a high-speed production method used primarily for non-ferrous metals like aluminum and zinc. In this process, molten metal is injected into a steel mold under high pressure. The molds, or dies, are reusable, making this method particularly efficient for mass production. Die casting is praised for its ability to produce uniform and precise parts with a smooth finish. However, it is limited to simpler shapes and is not suitable for all metal types, particularly ferrous metals like iron or steel.

4. Permanent Mold Casting

Permanent mold casting involves the use of reusable molds made from metal, typically iron or steel. This method allows for better dimensional accuracy and a finer finish compared to sand casting. The process entails pouring molten metal into pre-heated molds, which helps to solidify the metal quickly and evenly. Permanent mold casting is often used for producing high-quality components in industries such as automotive and consumer goods. However, the initial cost of metal molds can be high, making it less economical for low-volume production.

5. Slush Casting

Slush casting is a specialized method primarily used for producing hollow objects. In this technique, molten metal is poured into a mold and then rotated to coat the interior surfaces. After a sufficient thickness is achieved, the remaining molten metal is drained out, resulting in a lightweight, hollow part. This method is often used in the production of decorative or non-structural items, such as figurines and lighting fixtures. While slush casting allows for unique designs, it may not provide the strength required for load-bearing applications.

Conclusion

Casting is a critical manufacturing technique that accommodates various designs, materials, and production needs. Each type of casting offers its advantages and limitations, making it essential for engineers and manufacturers to choose the right method for their specific requirements. From the versatility of sand casting to the precision of investment casting, understanding these methods can ensure optimal results in producing high-quality components. As technology evolves, casting methods will continue to advance, enabling even greater innovation in metalworking and manufacturing processes.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025