Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Choosing the Right Impeller for Your Sump Pump Efficiency and Performance

Understanding Sump Pump Impellers A Key Component for Effective Drainage

Sump pumps are essential devices commonly found in basements and crawl spaces, where they play a critical role in preventing water accumulation. The heart of any sump pump system is the impeller, a critical component that influences the efficiency and effectiveness of the pump. In this article, we will explore the importance of sump pump impellers, how they work, and factors to consider when choosing the right impeller for your needs.

What is a Sump Pump Impeller?

An impeller is a rotating component of a pump that is responsible for moving water through the system. In the case of sump pumps, the impeller is designed to draw water into the pump and push it out through the discharge pipe. It operates on the principle of centrifugal force; as the impeller spins, it generates a pressure differential that causes water to flow from the low-pressure area at the inlet (sump basin) to the high-pressure area at the outlet.

Types of Impellers

There are several types of impellers used in sump pumps, with the two most common being the semi-vortex and the vortex impeller.

1. Semi-Vortex Impeller This type of impeller has a distinctive shape that allows it to effectively handle moderate levels of solids without clogging. It provides efficient flow and is commonly used in residential sump pumps.

2. Vortex Impeller This impeller type is specifically designed to handle larger solids and debris without the risk of clogging. Vortex impellers have a unique design that creates a swirling motion in the water, allowing larger particles to pass through unhindered.

Choosing the right type of impeller is essential, especially in environments where sediment and debris are common.

Why Impeller Performance Matters

The performance of the impeller directly affects the sump pump's ability to manage water effectively. A well-designed impeller can enhance flow rates and reduce the likelihood of clogging, ensuring that the pump operates efficiently. An inefficient impeller may lead to frequent cycling, inadequate drainage, or premature wear on the pump motor.

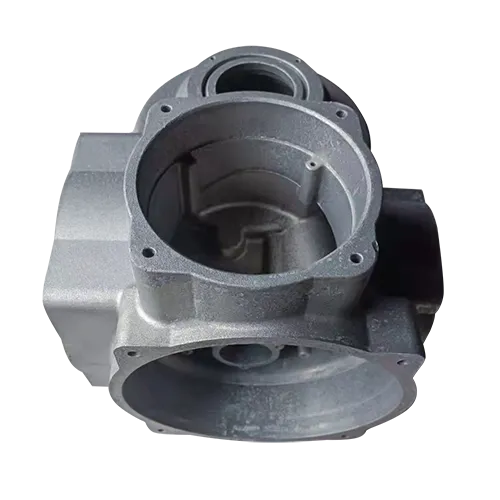

sump pump impeller

Factors to Consider When Selecting an Impeller

When selecting an impeller for a sump pump, several factors should be considered

1. Flow Rate The impeller’s design and size largely determine the pump’s flow rate (the amount of water it can move in a given time). Assess the expected water volume and choose an impeller that can handle those demands.

2. Size of Solids Consider the types of solids that may enter the sump pump system. If your area is prone to debris, a vortex impeller may be more beneficial than a semi-vortex one.

3. Material Composition Impellers can be made from various materials, including thermoplastics and cast iron. Thermoplastic impellers are resistant to corrosion and are typically less expensive but may not hold up as well under high temperatures or heavy-duty use. In contrast, cast iron impellers are more durable and capable of handling tough conditions.

4. Pump Design Ensure that the impeller is compatible with the sump pump’s design and specifications. Some pumps have unique mounting or design requirements that will limit the types of impellers you can use.

Maintenance and Care

To ensure optimal performance from your sump pump impeller, regular maintenance is crucial. Inspect the impeller periodically for debris buildup or signs of wear. Cleaning the impeller and surrounding components can prolong the pump’s life and maintain its effectiveness.

Conclusion

The sump pump impeller is a vital component that significantly impacts the effectiveness of water removal in basements and crawl spaces. By understanding the role and types of impellers, as well as considering key factors like flow rate, solid sizes, and material, homeowners can make informed decisions that enhance the performance of their sump pump systems. Proper care and maintenance ensure that these essential devices continue to operate efficiently, protecting your home from water damage.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025