Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Fév . 18, 2025 02:51

Back to list

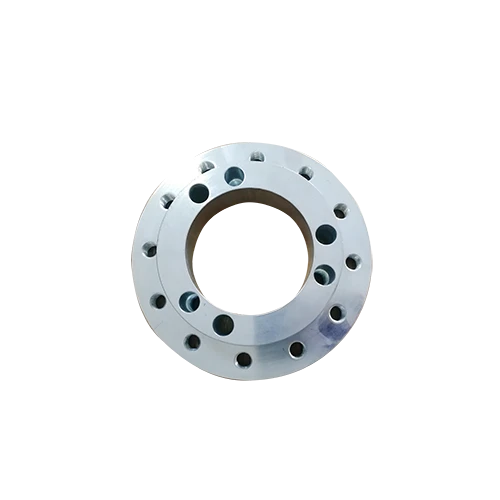

Motor shell housing

Stainless steel turbine housings are revolutionizing the automotive and aerospace industries in terms of performance and durability. This evolution stands at the intersection of cutting-edge technology and advanced metallurgical insights, making stainless steel housings a preferred choice across various applications.

When evaluating the trustworthiness of stainless steel turbine housings, one must consider the exhaustive testing protocols they undergo before reaching the market. These housings are subjected to rigorous quality controls, ensuring they withstand the onerous demands of real-world applications. Trust in these products is not just a marketing promise but a well-documented assurance backed by scientific testing and years of field application. The versatility of stainless steel extends beyond performance and sustainability, encompassing a broader spectrum of design applications. Its adaptability allows it to be used across a range of temperatures and pressures, reinforcing its role as a go-to material in diverse engineering sectors. Consequently, stainless steel turbine housings cater not only to current industrial standards but also anticipate future technological innovations. In terms of expertise, the metallurgy behind stainless steel involves intricate interactions between its primary components — notably chromium and nickel. These components enhance its properties, improving resistance to oxidation and thermal fatigue. Understanding these interactions allows manufacturers to fine-tune the properties of stainless steel, creating customized solutions specific to different operational needs. The emergence of advanced computational techniques has furthered our understanding of stainless steel's behavior under strain. Predictive modeling enables engineers to foresee potential failure points and design accordingly, further bolstering the reliability of stainless steel turbine housings. This expert-driven approach ensures a continuous improvement cycle, elevating the performance standards industry-wide. Finally, real-world experience underlines the strength of the trust users place in stainless steel turbine housings. Feedback from long-term use in automotive and aerospace applications provides valuable insights for ongoing development and refinement. Engaging with end-users allows for a feedback loop that not only inspires confidence but also fosters innovation driven by practical demands. In conclusion, stainless steel turbine housings embody a synthesis of strength, sustainability, and innovation — qualities highly sought after in today’s demanding industrial landscapes. As technology and environmental considerations continue to advance, the role of stainless steel in turbocharging solutions is positioned to grow, cementing its status as an integral component of modern engineering solutions.

When evaluating the trustworthiness of stainless steel turbine housings, one must consider the exhaustive testing protocols they undergo before reaching the market. These housings are subjected to rigorous quality controls, ensuring they withstand the onerous demands of real-world applications. Trust in these products is not just a marketing promise but a well-documented assurance backed by scientific testing and years of field application. The versatility of stainless steel extends beyond performance and sustainability, encompassing a broader spectrum of design applications. Its adaptability allows it to be used across a range of temperatures and pressures, reinforcing its role as a go-to material in diverse engineering sectors. Consequently, stainless steel turbine housings cater not only to current industrial standards but also anticipate future technological innovations. In terms of expertise, the metallurgy behind stainless steel involves intricate interactions between its primary components — notably chromium and nickel. These components enhance its properties, improving resistance to oxidation and thermal fatigue. Understanding these interactions allows manufacturers to fine-tune the properties of stainless steel, creating customized solutions specific to different operational needs. The emergence of advanced computational techniques has furthered our understanding of stainless steel's behavior under strain. Predictive modeling enables engineers to foresee potential failure points and design accordingly, further bolstering the reliability of stainless steel turbine housings. This expert-driven approach ensures a continuous improvement cycle, elevating the performance standards industry-wide. Finally, real-world experience underlines the strength of the trust users place in stainless steel turbine housings. Feedback from long-term use in automotive and aerospace applications provides valuable insights for ongoing development and refinement. Engaging with end-users allows for a feedback loop that not only inspires confidence but also fosters innovation driven by practical demands. In conclusion, stainless steel turbine housings embody a synthesis of strength, sustainability, and innovation — qualities highly sought after in today’s demanding industrial landscapes. As technology and environmental considerations continue to advance, the role of stainless steel in turbocharging solutions is positioned to grow, cementing its status as an integral component of modern engineering solutions.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS