Mobile:+86-311-808-126-83

Email:info@ydcastings.com

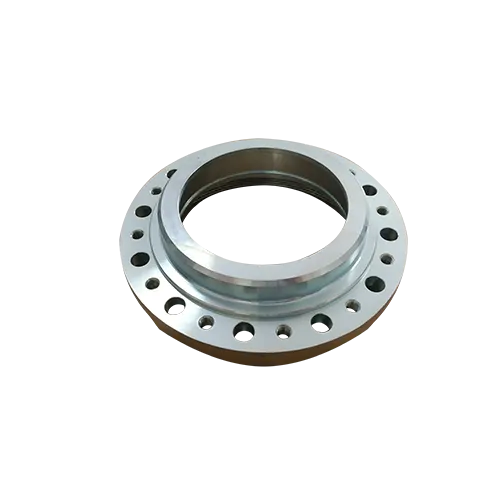

stainless pipe cap

Understanding Stainless Steel Pipe Caps Importance, Applications, and Benefits

Stainless steel pipe caps are essential components in various piping systems, providing a functional and aesthetic finish to the ends of pipes. These fittings are crucial in numerous industries, including oil and gas, plumbing, food processing, and chemical manufacturing. Understanding their importance, applications, and benefits can help industries optimize their operations and ensure system integrity.

What are Stainless Steel Pipe Caps?

Pipe caps are fittings designed to seal the ends of pipes, preventing the ingress of contaminants and the loss of fluids or gases. They are typically available in various sizes, thicknesses, and designs to suit different pipe specifications. Stainless steel is the preferred material for these caps due to its favorable qualities, including resistance to corrosion, high strength, and durability. Common grades of stainless steel used include 304 and 316, known for their excellent mechanical properties and resistance to oxidation and corrosion.

Importance of Pipe Caps

The significance of stainless steel pipe caps cannot be overstated. They serve several vital functions

1. Sealing Pipe caps effectively close off the ends of pipes, providing a tight seal that prevents leaks and contamination. This is particularly crucial in systems that transport hazardous materials or in applications where cleanliness is a priority.

2. Protection By capping the ends of pipes, these fittings protect the internal surfaces from dust, debris, and moisture during handling, storage, and transport. This protection helps to maintain the integrity of the pipes and ensures optimal performance.

3. System Integrity Capping pipes is essential for maintaining the overall integrity of a piping system. It prevents backflow and pressure loss, ensuring consistent flow and efficient operation. This is particularly important in pressure-sensitive applications.

4. Aesthetic Finish In some applications, especially in visible areas, stainless steel pipe caps provide a clean and professional appearance. They can enhance the overall look of piping installations, contributing to the aesthetics of an environment.

Applications of Stainless Steel Pipe Caps

Stainless steel pipe caps find applications across a wide range of industries

- Oil and Gas In the oil and gas sector, pipe caps are used in pipeline systems to seal ends during construction or maintenance operations. They ensure safety and prevent leaks in high-pressure environments.

stainless pipe cap

- Plumbing In residential and commercial plumbing, caps are used to terminate water or drainage lines, ensuring no unwanted substances enter the system.

- Food Processing The food industry requires strict hygiene standards. Stainless steel pipe caps are used to seal pipes in processing plants, ensuring that the products remain uncontaminated.

- Chemical Manufacturing In chemical processes where reactive substances are handled, stainless steel caps provide a reliable seal that protects both the environment and the employees.

- Construction In construction projects, pipe caps can be used for temporary sealing during setup and to prevent moisture entry into newly laid pipelines.

Benefits of Using Stainless Steel Pipe Caps

Opting for stainless steel pipe caps comes with several advantages

1. Corrosion Resistance Stainless steel offers superior resistance to rust and corrosion, extending the lifespan of piping systems and reducing maintenance costs.

2. Durability These caps are robust and can withstand high-pressure environments, making them ideal for challenging applications.

3. Versatility Available in a range of sizes and styles, stainless steel pipe caps can accommodate various types of pipes and applications.

4. Temperature Tolerance Stainless steel can endure extreme temperatures, making it suitable for both high-temperature and cryogenic applications.

5. Recyclability Stainless steel is 100% recyclable, making it an environmentally friendly choice for piping systems.

In conclusion, stainless steel pipe caps are critical components that enhance the functionality and longevity of piping systems across various industries. Their importance in sealing, protecting, and maintaining the integrity of pipes cannot be understated. By understanding their applications and benefits, industries can make informed choices that lead to improved efficiency and safety in operations. Whether in construction, plumbing, or chemical manufacturing, investing in high-quality stainless steel pipe caps is a decision that pays off in the long run.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025