Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Stainless Steel Casting Foundry Solutions for Precision Components and Innovative Designs

The Importance of Stainless Steel Casting Foundries

Stainless steel casting foundries play a crucial role in various industries by transforming raw materials into high-quality, durable components. These foundries utilize advanced technologies and methods to create parts that are resistant to corrosion, high temperatures, and mechanical wear. This article delves into the significance of stainless steel casting foundries, their processes, and their contributions to different sectors.

Understanding Stainless Steel Casting

Stainless steel casting involves pouring molten stainless steel into molds to create intricate shapes and designs. This process offers several advantages over traditional machining methods, such as reduced waste and the ability to produce complex geometries. Common methods of stainless steel casting include investment casting, sand casting, and centrifugal casting, each serving specific purposes based on the desired application.

Investment casting, often referred to as lost-wax casting, is particularly popular for producing precision parts with excellent surface finishes. Sand casting, on the other hand, is favored for larger components due to its cost-effectiveness and flexibility. Centrifugal casting is ideal for cylindrical parts, leveraging centrifugal force to create denser and stronger structures.

Industries That Benefit from Stainless Steel Casting

Stainless steel casting foundries serve a plethora of industries, including automotive, aerospace, medical, oil and gas, and food processing. Each of these sectors demands high-quality materials that can withstand harsh conditions while maintaining performance and safety standards.

1. Automotive Industry In the automotive sector, stainless steel components are used for exhaust systems, transmission parts, and structural applications. The material's corrosion resistance ensures longevity and reliability, which are critical in vehicular design.

2. Aerospace Sector Aerospace applications require components that can endure extreme temperatures and pressures. Stainless steel castings are used in engine parts, landing gear, and structural components due to their strength-to-weight ratio and ability to resist fatigue.

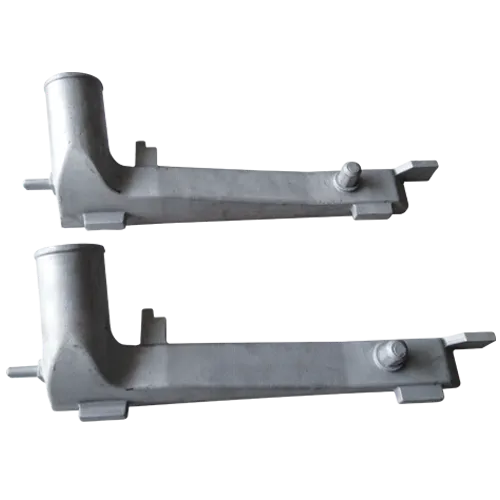

stainless casting foundry

3. Medical Industry In the medical field, stainless steel is a preferred material for surgical instruments, implants, and various medical devices. Its biocompatibility and resistance to sterilization processes make it an ideal choice for applications where hygiene and safety are paramount.

4. Oil and Gas The oil and gas industry relies on durable components capable of withstanding harsh environments. Stainless steel castings are utilized in valves, pumps, and piping systems, where resistance to corrosion from aggressive fluids is essential.

5. Food Processing Stainless steel's non-reactive nature makes it suitable for food processing equipment. Cast components are used in machinery, storage tanks, and piping systems, ensuring compliance with health standards and maintaining food safety.

The Advantages of Stainless Steel Casting

The choice of stainless steel offers numerous benefits, making it a superior material for many applications. Key advantages include

- Corrosion Resistance Stainless steel exhibits excellent resistance to rust and corrosion, making it suitable for use in wet or chemical-laden environments. - Strength and Durability The material is known for its strength, which allows for the production of thinner, lighter parts that can endure significant stress. - Versatility Stainless steel can be alloyed with various elements to achieve desired characteristics, such as increased hardness or improved weldability, making it adaptable to diverse applications. - Aesthetic Appeal Stainless steel has a modern, sleek appearance, making it a popular choice in consumer products, architecture, and design.

Conclusion

In conclusion, stainless steel casting foundries are integral to modern manufacturing, providing essential components across a range of industries. Their ability to produce high-quality, durable parts through various casting techniques ensures that industries can meet their specific needs while maintaining safety and efficiency. As technological advancements continue to shape the casting processes, the future of stainless steel foundries looks promising, highlighting their importance in sustainable manufacturing and innovation. As businesses strive for efficiency and quality, the contributions of stainless steel casting foundries will undoubtedly remain vital in the global marketplace.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025