Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Benefits and Applications of Stainless Steel Investment Casting Techniques

Investment Casting A Precision Technique for Modern Manufacturing

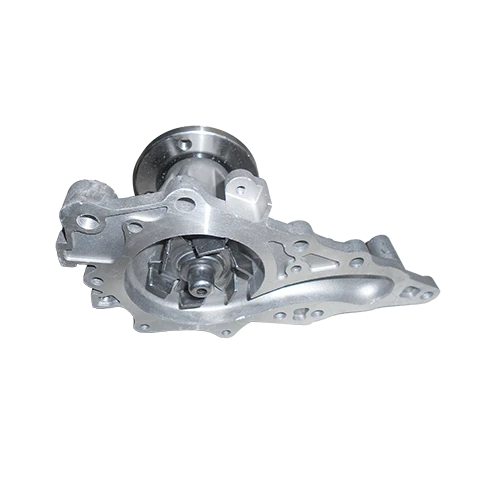

Investment casting, often referred to as lost-wax casting, is a sophisticated metal-forming process that has been favored by manufacturers for its precision and ability to produce complex geometries. This ancient technique has evolved significantly due to advancements in technology and materials, making it an essential method in various industries, including aerospace, automotive, and medical equipment.

The process begins with creating a wax pattern of the desired part, which is coated with a ceramic shell. This shell is built up in layers to ensure that it can withstand the high temperatures involved in the casting process. Once the shell is hardened, the wax is melted away, leaving a hollow ceramic mold. The mold is then heated to remove any residual wax and to prepare it for pouring molten metal.

Investment Casting A Precision Technique for Modern Manufacturing

Moreover, investment casting can accommodate a wide range of materials, including steel, aluminum, and even superalloys, which are critical for high-temperature applications. The versatility of materials means that companies can tailor their products to meet specific performance requirements without changing the manufacturing process.

ss investment casting

The investment casting process is not only economically advantageous but also environmentally friendly. Because the method minimizes waste, it allows for efficient use of materials. Any excess metal can be remelted and reused, reducing the environmental impact often associated with manufacturing processes. Additionally, the casting process often results in parts that would otherwise require extensive machining, leading to less energy consumption and lower costs.

Another aspect worth mentioning is the scalability of investment casting. This technique is suitable for both small-scale production runs and large-scale production, making it adaptable to the needs of various businesses. From prototypes to full production, investment casting offers flexibility that can accommodate the dynamic demands of the market.

However, it is essential to highlight that while investment casting offers numerous benefits, it also comes with challenges. The initial setup costs for creating the wax patterns and ceramic molds can be high, which may deter smaller companies from utilizing this method. Additionally, the complexity of the process requires skilled labor and sophisticated equipment, adding to the overall investment.

In conclusion, investment casting is a remarkable manufacturing process that combines ancient techniques with modern technology. Its precision, material versatility, and efficiency make it invaluable in numerous industries. As manufacturers continue to seek ways to innovate and improve their processes, investment casting will undoubtedly remain at the forefront, providing solutions that meet the increasing demands for high-quality, precision-engineered parts. Whether it’s in the production of flight-critical components in aerospace or sophisticated medical devices, investment casting is pivotal in shaping the future of manufacturing. The continued evolution of this method promises to enhance productivity while meeting stringent quality standards, thereby solidifying its place in the manufacturing landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025