Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Silicone Solutions for Enhanced Metal Casting Applications and Techniques

Silicone for Metal Casting An Innovative Approach to Precision and Efficiency

The world of manufacturing has consistently evolved over the years, seeking better methods to enhance efficiency, quality, and precision in production. Among the myriad of materials and technologies employed in this journey, silicone has gained notable traction, particularly in the realm of metal casting. Its unique properties make it an ideal candidate for various applications, ranging from prototypes to final components in industrial settings.

Understanding Silicone

Silicone is a synthetic material known for its elasticity, heat resistance, and durability. Unlike traditional plastics or rubbers, silicones can withstand extreme temperatures, making them suitable for a wide range of applications. Chemically, silicones are polymers made up of silicon, oxygen, carbon, and hydrogen, which provide them with their distinctive qualities.

Silicone Molds in Metal Casting

One of the most prominent applications of silicone in metal casting is the creation of molds. Traditional metal casting often utilizes rigid materials like metal or plaster. However, these methods can be cumbersome and time-consuming, often resulting in lengthy production cycles. Silicone molds, on the other hand, offer several advantages

1. Flexibility and Detail Silicone molds can capture intricate details and complex shapes with remarkable fidelity. This precision is especially beneficial when casting delicate features that would be challenging to achieve with traditional materials.

2. Ease of Use Silicone molds are lightweight and easy to manipulate, reducing the labor involved in preparing and handling molds. This factor leads to quicker turnaround times and increased productivity in the casting process.

3. Reusable Silicone has the advantage of durability and reusability. High-quality silicone molds can endure numerous casting sessions without losing their integrity, offering a cost-effective solution for manufacturers.

4. Wide Range of Compatibility Silicone molds can be used with various casting materials, including metals, resins, and even ceramics. This versatility allows for broader applications across different industries.

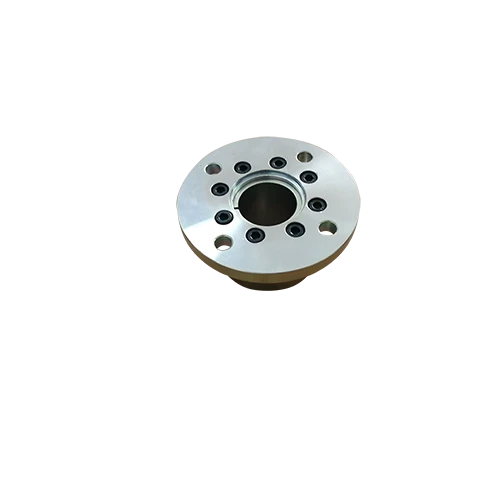

silicone for metal casting

5. Temperature Resistance Silicone’s ability to withstand high temperatures ensures that it remains stable during the casting process. It can accommodate the heating and cooling cycles involved without deforming or compromising the cast.

Applications in Industries

Silicone molds are becoming increasingly popular across various sectors. In the automotive industry, they are used for casting components that require high precision and strength. In aerospace, where the tolerances can be exceptionally tight, there is a growing reliance on silicone to produce protective housings and parts. Additionally, the electronics sector has also adopted silicone molds for creating enclosures and other intricate components.

In art and design, silicone casting has revolutionized the way artists and designers produce their works. By creating silicone molds of sculptures or artistic pieces, they can replicate works with great fidelity, allowing for wider distribution while retaining the original's essence.

Future Trends

As technology continues to advance, the future of silicone use in metal casting looks promising. Innovations in silicone formulations are expected to enhance durability, heat resistance, and flexibility even further. Additionally, the incorporation of digital technologies, such as 3D printing, with silicone mold-making could lead to more efficient and customized production processes.

Moreover, as industries increasingly focus on sustainability, silicone's longevity and reusability stand to contribute to more sustainable manufacturing practices. With ongoing advancements, the potential for silicone in metal casting could reshape production methodologies and foster new opportunities for creativity and precision in manufacturing.

Conclusion

Silicone's role in metal casting is a testament to the material's versatility and practicality. Its capacity to create high-precision molds efficiently has transformed the landscape of manufacturing. As industries continue to search for ways to enhance quality while reducing costs and production times, silicone stands out as a pivotal resource. Whether for automotive components, aerospace engineering, or artistic endeavors, the future of silicone in metal casting is bright, promising a new era of innovation in manufacturing processes.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025