Mobile:+86-311-808-126-83

Email:info@ydcastings.com

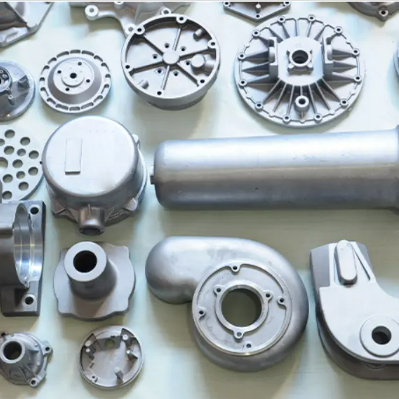

sand casting products

Sand Casting Products An Overview

Sand casting is one of the oldest and most versatile methods of metal casting. It involves creating a mold from sand and using it to form metal objects. This method is widely used in various industries to produce complex shapes and components with high precision. In this article, we will explore the sand casting process, its advantages, applications, and the types of products that can be manufactured through this efficient and cost-effective technique.

The Sand Casting Process

The sand casting process begins with the creation of a pattern, which is a replica of the final product. Patterns are usually made of metal, plastic, or wood and can be created through various methods, including 3D printing. Once the pattern is ready, it is placed in a mixture of sand and a bonding agent, usually clay. The sand is compacted around the pattern to form a mold.

After the mold is prepared, the pattern is removed, leaving a cavity that mirrors the shape of the original pattern. This cavity is then heated, and molten metal is poured into it. Once the metal cools and solidifies, the mold is broken apart to retrieve the final casting product. The sand can often be reused for subsequent castings, making the process environmentally friendly.

Advantages of Sand Casting

1. Cost-Effectiveness Sand casting is relatively inexpensive compared to other casting methods. The materials used (sand and bonding agents) are inexpensive and readily available, making it an ideal choice for small and medium-sized production runs.

2. Flexibility A wide variety of metals can be cast using sand casting, including aluminum, iron, and steel. This flexibility allows manufacturers to produce different products without needing extensive changes to the equipment or molds.

3. Complex Geometries Sand casting can produce intricate shapes and detailed designs. This capability makes it suitable for manufacturing complex components that might be challenging with other methods.

4. Large Parts With sand casting, it is possible to cast large parts that are often difficult to produce using other methods, such as die casting.

5. Reusability of Molds The sand used in the molds can often be reused multiple times, reducing waste and production costs.

Applications of Sand Casting

Sand casting finds its applications across a variety of industries, including

sand casting products

- Automotive Industry Many automotive components, such as engine blocks, transmission cases, and various structural parts, are produced using sand casting. Its ability to create parts with precision and strength is crucial for vehicle performance and safety.

- Aerospace In the aerospace industry, sand casting is used to manufacture components that require high strength-to-weight ratios, such as brackets and housings

.- Marine Sand casting is also employed in the production of marine equipment, including propellers, pumps, and various housings that need to withstand harsh environments.

- Construction Parts such as valves, fittings, and other structural components are often sand cast due to the method's durability and reliability.

Types of Sand Casting Products

The range of products that can be manufactured through sand casting is vast, covering both small and large components. Common products include

1. Engine Components As previously mentioned, many internal combustion engine components are cast using this method. Engine blocks and cylinder heads are great examples of sand-cast products.

2. Machinery Parts Sand casting is essential in producing gears, housings, and brackets for industrial machinery.

3. Art and Sculpture Artists and sculptors often utilize sand casting for creating artworks and sculptures, thanks to the method's ability to capture intricate details.

4. Tools and Hardware Sand casting can also be used to produce hand tools, fittings, and other hardware products commonly found in households and industries.

Conclusion

Sand casting is a fundamental method of producing durable and complex metal components. Its cost-effectiveness, versatility, and ability to cater to a vast range of applications make it indispensable in modern manufacturing. As industries continue to evolve, sand casting will remain a vital technique for creating high-quality products tailored to the needs and specifications of various sectors. Whether in automotive, aerospace, or art, the significance of sand casting products will continue to resonate for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025