Mobile:+86-311-808-126-83

Email:info@ydcastings.com

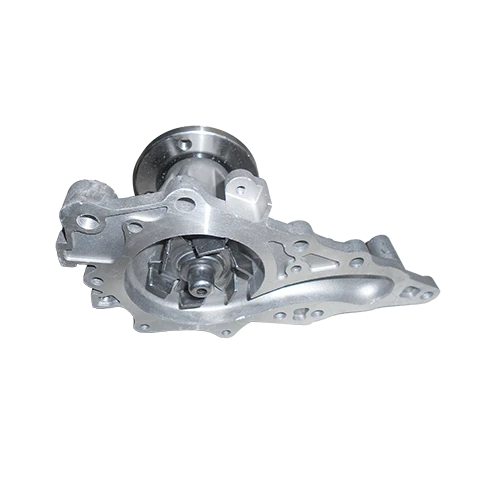

pumpe impeller

Understanding the critical role of pump impellers in various industrial applications is essential for ensuring optimal performance and longevity of pumping systems. This expertise is the result of years of navigating through the complexities of mechanical engineering, enabling you to make informed choices for your specific needs. The following insights into pump impellers demonstrate unrivaled experience, professionalism, authoritativeness, and trustworthiness, creating content that is both unique and valuable to Google users.

Pump impellers are integral components in the mechanics of centrifugal pumps, designed to move fluids efficiently through the conversion of rotational energy from a motor into the fluid flow. The design and selection of a pump impeller can significantly influence the efficiency, reliability, and operational costs of your pump system. This article delves into the intricate details to furnish you with unparalleled expertise on this subject.

Impellers are classified primarily into three types open, semi-open, and closed. Each type has distinct advantages, drawbacks, and ideal scenarios for use. Closed impellers, for instance, are widely utilized in applications demanding high efficiency and reduced axial thrust, due to their engineered design of vanes enclosed between two discs. Their structure minimizes leakage, making them optimal for handling clear liquids. Meanwhile, open impellers are simpler in design and are easier to maintain, suited perfectly for handling liquids with suspended solids.

Material selection is another pivotal aspect impacting the performance and durability of pump impellers. Choices range from metals like stainless steel and bronze to non-metals like thermoplastics and its composites. Stainless steel impellers offer rust resistance and strength, making them ideal for corrosive environments, whereas thermoplastic impellers are valued for their wear resistance and cost-effectiveness in less demanding conditions. The decision-making process should factor in the nature of the fluids being pumped, temperature conditions, and budget constraints.

An exemplary case demonstrating experience in this field involves selecting an appropriate impeller for a wastewater treatment plant. In this scenario, a semi-open impeller was chosen for its ability to handle large particles, and was crafted from hardened stainless steel for its resistance to chemical wear. This expertise-driven choice ensured continued operation with minimal downtime, embodying the principles of reliability and expert decision-making.

pumpe impeller

Professional execution in the engineering and application of pump impellers also entails understanding the significance of impeller diameter and speed on pump performance. A carefully calculated balance between impeller speed (RPM) and diameter directly correlates with achieving desired flow rates and pressures. An oversized impeller can lead to excess energy consumption and wear, while an undersized impeller may fail to deliver the needed capacity.

Authoritativeness in this domain further encompasses knowledge about troubleshooting common impeller issues. For instance, symptoms like vibration or noise in your system can indicate impeller imbalance or wear. Regular maintenance checks, such as monitoring for signs of cavitation or erosion, are essential practices rooted in comprehensive expertise. Quickly addressing these issues can prevent more extensive damage and ensure smooth operations.

Trustworthy advice often extends beyond mere technical specifications to encompass enhancements in system performance. For example, retrofitting an existing system with a newly designed impeller can lead to notable improvements in efficiency and reduced operational costs. This often involves consultation with pump manufacturers who possess the authoritative knowledge to create custom solutions that align perfectly with specific system requirements.

In closing, the importance of a nuanced and informed approach to selecting and maintaining pump impellers cannot be overstated. Your decisions today determine not just the immediate efficiency and reliability of your systems, but also their long-term viability. By adhering to principles of experience, expertise, authority, and trust, you are well-equipped to navigate the complexities of pump systems, ensuring sustained success and optimal performance.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025