Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Comparative Analysis of Pump Diffusers and Impellers in Fluid Dynamics Applications

The Dynamics of Pumps Analyzing Diffusers and Impellers

Pumps are essential components in various industrial applications, providing the necessary force to move fluids through systems. Among the many components that contribute to their effectiveness, diffusers and impellers stand out due to their crucial roles in fluid dynamics. Understanding how these elements work together is vital for optimizing pump performance, enhancing efficiency, and ensuring reliability in operations.

The Role of Impellers

An impeller is a rotating component of a pump designed to add energy to the fluid being moved. Typically featuring blades that can vary in shape and configuration, impellers perform the critical function of converting rotational kinetic energy from the motor to the fluid's flow energy. When the impeller spins, it imparts momentum to the fluid, pushing it outward towards the volute (the casing of the pump) or any discharge piping.

The design of an impeller can significantly affect the overall pump performance. There are several types, including open, semi-open, and closed impellers, each serving different applications. Closed impellers, with two shrouded sides, tend to offer higher efficiency and improved pressure generation compared to open impellers, which are easier to clean but may result in lower efficiencies. The specific design chosen for a particular application will depend on factors such as the nature of the fluid, desired flow rate, and pressure requirements.

Understanding Diffusers

Diffusers work in conjunction with impellers to enhance the pump's performance. After the fluid leaves the impeller, it enters the diffuser, which is a stationary component that gradually changes the fluid's velocity and converts kinetic energy into pressure energy. This transition is crucial for achieving the desired output pressure.

The diffuser's design generally involves a divergent passage, allowing the fluid to slow down and expand. As the fluid decelerates, its pressure rises, which is fundamental for pumping applications requiring high discharge pressure. The efficiency of a diffuser also depends on its shape and the angle at which the fluid enters; an optimally designed diffuser can facilitate a smoother flow, reducing turbulence and energy losses.

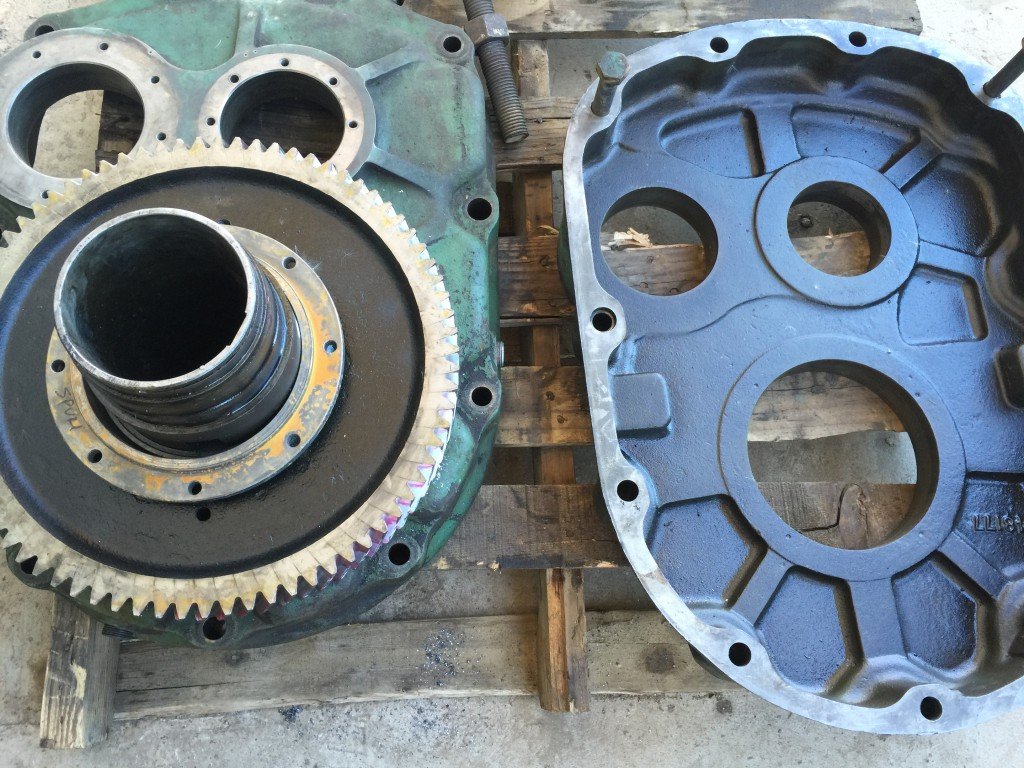

pump diffuser and impeller

Interaction Between Impellers and Diffusers

The synergy between impellers and diffusers is where the true efficiency of a pump is realized. When fluid exits the impeller, it possesses high velocity and low pressure. As it enters the diffuser, the change in area allows for an increase in pressure as described before. Ideally, the design and operational parameters should be synchronized to maximize the energy transfer, thus minimizing losses.

One critical factor in this interaction is the pump curve, which relates flow rate, head pressure, and efficiency. A well-matched impeller and diffuser can help maintain a predictable pump curve, ensuring that the pump operates within its optimal performance range. If the impeller is too large for the diffuser, or vice versa, inefficiencies will arise, leading to either inadequate performance or energy wastage.

Applications and Considerations

Pumps equipped with well-designed impellers and diffusers find their applications in various sectors, including wastewater treatment, chemical processing, oil and gas, and food processing. In each of these applications, the selection of appropriate pump components is critical for maintaining system integrity and functionality.

In designing pumps, engineers must consider fluid characteristics, such as viscosity, density, and corrosiveness, alongside operational parameters like temperature and pressure. Such considerations inform the choice of materials and the design of both the impeller and diffuser, ensuring longevity and reliability under varying conditions.

Conclusion

In conclusion, the interplay between impellers and diffusers is fundamental to pump efficiency and performance. By effectively converting energy and managing fluid dynamics, these components work together to achieve the desired flow and pressure outputs. Understanding their roles allows engineers and operators alike to enhance pump design, select suitable applications, and ultimately ensure optimal system performance. As technology advances, ongoing innovations in impeller and diffuser design will continue to shape the future of fluid management in industrial applications, driving efficiency and sustainability.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025