Mobile:+86-311-808-126-83

Email:info@ydcastings.com

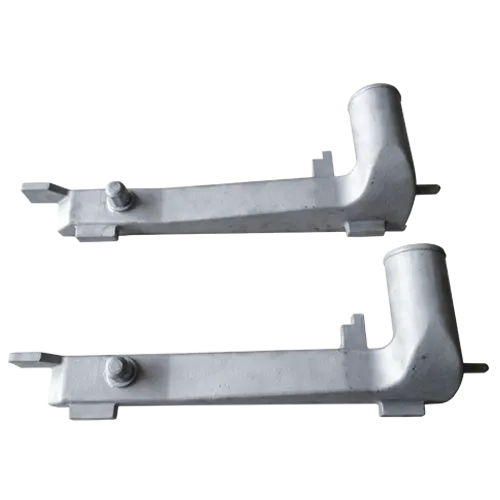

High-Precision Aluminum Casting Techniques for Superior Quality and Performance

Precision Aluminum Casting An Overview

Precision aluminum casting is a sophisticated process that leverages the unique properties of aluminum to produce intricate and high-quality components. This technique is widely used across various industries, including automotive, aerospace, electronics, and industrial machinery, due to its ability to meet stringent specifications and requirements.

Understanding Precision Aluminum Casting

Precision aluminum casting involves the creation of metal parts by pouring molten aluminum into a mold that shapes the liquid metal into the desired form. The molds are typically made from materials such as steel, sand, or resin, allowing for a high degree of detail and accuracy in the final product. The process can be categorized into several methods, including sand casting, investment casting, die casting, and permanent mold casting. Each method has its advantages and is chosen based on specific project requirements.

1. Sand Casting This is one of the most common methods used for aluminum casting. It involves creating a mold from sand, which is then packed around a pattern of the desired shape. Once the molten aluminum is poured into the mold and cooled, the sand is removed, leaving behind the cast part. Sand casting is particularly cost-effective for large components and smaller production runs.

2. Investment Casting Also known as lost-wax casting, this method allows for highly detailed and complex designs. A wax pattern is coated in a ceramic material, which is then heated to remove the wax, leaving a hollow mold. Molten aluminum is poured into the mold, providing exceptional precision. This technique is often used for intricate parts that require tight tolerances.

3. Die Casting In this process, molten aluminum is injected into a steel mold under high pressure. This method is highly efficient for producing large volumes of uniform components, as it can achieve quick cycle times and excellent surface finishes. Die casting is ideal for high-volume production in automotive and consumer products.

4. Permanent Mold Casting This method uses reusable metallic molds to produce parts. The aluminum is poured into the mold, and once cooled, the mold is removed to reveal the finished piece. This technique offers good dimensional accuracy and surface finish, making it suitable for production runs where consistency is key.

precision aluminum casting

Advantages of Precision Aluminum Casting

Precision aluminum casting presents numerous advantages that make it a preferred choice in manufacturing. The lightweight nature of aluminum, combined with its strength and resistance to corrosion, makes it an ideal material for producing durable components. Furthermore, casting allows for the integration of complex geometries that would be difficult or impossible to achieve with other manufacturing processes.

Another significant benefit is the cost-effectiveness in large production runs. Once the initial investment in molds is made, the cost per unit decreases substantially, making it suitable for mass production. Additionally, the versatility of aluminum casting enables manufacturers to produce parts with varying thicknesses, high strength-to-weight ratios, and excellent thermal conductivity.

Applications of Precision Aluminum Casting

The applications of precision aluminum casting are vast and varied. In the automotive industry, aluminum castings are used for engine blocks, transmission housings, and various structural components, significantly reducing weight and improving fuel efficiency. In aerospace, precision aluminum parts are crucial for aircraft components that demand high strength and lightweight materials.

In the electronics sector, aluminum casting is used to create housings for electrical devices and components that require effective heat dissipation. Moreover, in industrial machinery, precision cast aluminum parts are essential for machinery that operates under high-stress conditions.

Conclusion

Precision aluminum casting represents a critical technology in modern manufacturing, offering a unique blend of strength, lightweight, and intricate design capabilities. As industries continue to evolve, the demand for high-precision components that aluminum casting can provide is only expected to grow. Understanding the various casting methods and their applications is essential for manufacturers looking to optimize their production processes and deliver high-quality products to meet market demands. Through continued innovation and advancements in casting technology, the future of precision aluminum casting looks promising, offering ever-increasing opportunities for efficiency and design capabilities.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025