Mobile:+86-311-808-126-83

Email:info@ydcastings.com

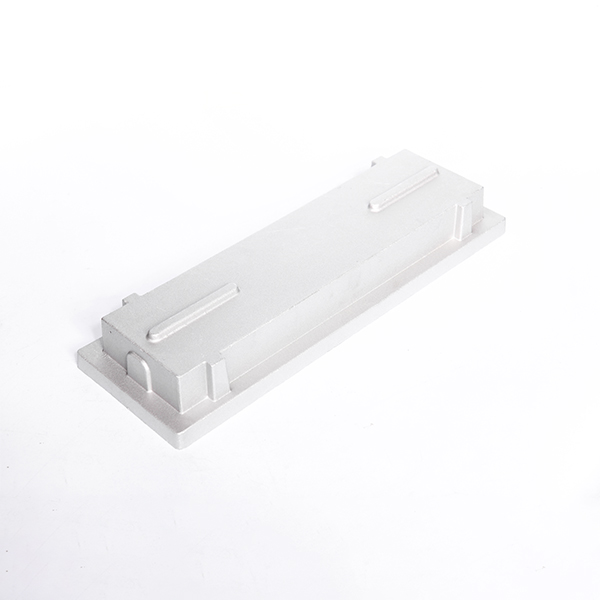

Precision Engineered Motor Housing Solutions - Durable & Efficient

As the motor housing segment rapidly evolves in automotive and industrial sectors, products like the Bottom Shell are setting new benchmarks for durability, efficiency, and design innovation. With an ever-increasing focus on engine oil pan, automobile oil pan, and components such as the engine sump and baffled oil pan, OEMs and Tier 1 suppliers demand exceptional technical performance, cost-efficiency, and customized solutions for diverse application environments.

- Automotive lightweighting: According to Statista 2023, the global motor housing & oil pan market is projected to reach USD 6.7 billion by 2027, driven by lightweight cast aluminum solutions—growth CAGR at 5.3% (2022-2027).

- Environmental compliance: Rapid transition towards stricter ISO 14001:2015 and SAE J431 standards for automotive castings, necessitating advanced materials and eco-friendly manufacturing.

- Application Diversification: Use of automobile oil pan and engine sump expands from automotive to petrochemical, metallurgical, renewable energy, and marine sectors.

A premium motor housing (alternately Bottom Shell) not only acts as a protective enclosure but also optimizes thermal management, oil retention, and vibration damping. Key design challenges:

- Corrosion resistance against aggressive lubricants and environmental agents

- Excellent sealing (conforms to ANSI B16.5 standards)

- Fatigue & impact resistance—prolonged lifetime above 3 million cycles

- Optimized surface roughness (Ra < 1.6 µm) for sealing & oil flow

| Type | Main Material | Standard | Weight (kg) |

Corrosion Resistance (ASTM B117) |

Fatigue Life (cycles) |

Oil Capacity (L) |

Industrial Use |

|---|---|---|---|---|---|---|---|

| Standard Motor Housing | ADC12 Aluminum Alloy | ISO 9001, SAE J1085 | 4.1–5.2 | ≥500 hr (salt spray) | 2 million | 5.2–7.0 | Automotive, HVAC |

| Engine Oil Pan | EN-GJL-250 Cast Iron | DIN EN 1561 | 6.2–8.8 | ≥1000 hr | 3 million | 7.5–13.2 | Trucks, Construction |

| Baffled Oil Pan | 5083 Aluminum (welded) | ISO 16949:2016 | 3.4–4.6 | ≥700 hr | 4 million | 4.8–6.5 | Motorsport, Marine |

| Bottom Shell | ADC12/ADC6/6061-T6 | ISO 9001, ANSI B16.5 | 3.2–5.1 | ≥1100 hr | >5 million | 5.5–8.0 | Petrochemical, Metallurgy |

- Key Step: High-pressure die casting guarantees fine-grain structure—meets ISO 8062-3 CT8 accuracy and minimal porosity.

- Material Control: ADC12/6061 alloys undergo X-ray and chemical composition checks.

- CNC Machining Standard: Spot-face, flange, and thread tolerances conform to ISO 2768-m.

- NDT: Each unit passes leak test & ultrasonic inspection.

Learn more: Video - Bottom Shell Manufacturing Process

Watch Process Video| Parameter | Value / Range | Reference Standard |

|---|---|---|

| Material Composition | ADC12, ADC6, 6061-T6 Al alloy | ASTM B179, GB/T 15115 |

| Coating/Finish | Epoxy or anodized; Ra < 1.6 µm | ISO 9227, ISO 1302 |

| Wall thickness | 3.5–6.5 mm | ISO 8062-3 |

| Dimensional Tolerance | ±0.1 mm (key areas) | ISO 2768-mK |

| Weight | 3.2–5.1 kg | Actual measurement |

| Service Life | >7 years / ≥5 million cycles | ISO 15551-1 |

| Leakage Rate | <0.01 cc/min @ 0.5Mpa | ANSI B16.5, ISO 5208 |

- Material Superiority: Using high-grade ADC12/6061-T6 ensures lightweight structure and corrosion resistance (tested ≥ 1100 hours in salt spray, per ASTM B117).

- High Dimensional Accuracy: CNC machining achieves tolerances up to ±0.1 mm, ideal for engine oil pan and high-pressure applications.

- Industry Standards: Compliance with ISO 9001, ANSI B16.5, and ISO/TS 16949 recognized by global OEMs.

- Customizable Design: Flexible baffled, ribbed, or deep-sump options for specific oil management needs—especially in motorsports or commercial vehicles.

- Anti-leak Assurance: All motor housings receive 100% hydro/leak test per ISO 5208.

| Manufacturer | Production Method | Materials | Main Market | Certifications | Key Advantage |

|---|---|---|---|---|---|

| Y&D Castings Bottom Shell |

Gravity & HPDC, CNC | ADC12, 6061-T6 | Global | ISO 9001, ANSI, IATF 16949 | 7+ years service, custom design |

| Aisin Seiki | Gravity Casting, Machining | Aluminum alloys | Asia, EU | ISO/TS 16949 | OEM supply, integration |

| Dana Incorporated | High-pressure Die Casting | Al, Steel | Americas | ISO 9001, ISO 14001 | Large batch, global presence |

| Mahle | Die casting/CNC | Al alloys | EU, NA | ISO 9001 | Lightweight, thermal control |

- Materials Engineering: Alloy blend tailored for high thermal stability and corrosion resistance

- Rapid Prototype to Batch Production: Full DFM support, 4-week delivery for initial samples

- Integrated Inspection: Full 3D CMM, X-ray, leak, and tensile testing in-house

- Industry Trust: 15+ years serving automotive, energy, and petrochemical majors

- Application-Specific Optimization: Baffled design for high-G applications, deep sumps for extended oil reserves

- Eco Certification: All processes meet RoHS, REACH directives

- Electric Drive Units: Lightweight motor housing covers for BEV’s increase energy efficiency by 5–8% (tested by SAE Tech).

- Heavy-duty Engine Sump: Custom ribbing and deep-draw aluminum for mining trucks support intensive usage with low leak rate (<0.01 cc/min), reducing annual downtime by 18%.

- Baffled Oil Pan for Motorsport: Lateral groove and anti-slosh design minimize oil starvation on high-G turns, as cited in Engineering Tips forums.

- Corrosive Process Liquids: Specialty coatings used in petrochemical sumps lengthen shell lifespan by 40% over uncoated units.

- “The motor housing bottom shell we sourced from Y&D outperformed our existing supplier by 30% in lifecycle fatigue tests—especially for our heavy-duty off-road fleet” – Senior Engineer, SinoTruk

- “Short lead time and full compliance with ISO and ANSI standards made mass production for our marine engine product line smooth and defect-free.” – Procurement Specialist, Wartsila China

- 1. What are the most common motor housing materials?

- ADC12 (Al-Si-Cu alloy), ADC6, and 6061-T6. These alloys combine excellent castability, thermal conductivity, and corrosion resistance for demanding automotive, industrial, and marine environments.

- 2. What is a baffled oil pan and why is it used?

- A baffled oil pan integrates internal walls or grooves to prevent oil from sloshing during sharp acceleration, braking, or cornering—critical for motorsport/high-performance engines to maintain lubrication pressure.

- 3. Which inspection standards are applied for bottom shell (motor housing)?

- ISO 8062-3 (casting tolerance), ISO 2768-mK (machining tolerance), ISO 5208/ANSI B16.5 (leakage test), and NDT checks per ASTM E1444.

- 4. How do I select between aluminum and cast iron engine oil pans?

- Aluminum offers significant weight savings (>30%), improved thermal dissipation, and enhanced corrosion protection, suited for fuel efficiency and performance; cast iron provides extra rigidity, common in heavy machinery.

- 5. What defines automobile oil pan capacity?

- Determined by engine displacement and oil circulation requirements; typical ranges from 4.5L (compact cars) up to 14L (HD trucks), with design optimization to maximize clearance and sump volume.

- 6. What installation standards apply to motor housing components?

- Flange and fastener dimensions per ISO 4017, threaded holes with ISO 965-1 tolerances, flatness under 0.08 mm per meter to ensure seal and vibration resistance.

- 7. What is the warranty and service life for Bottom Shell products?

- Y&D Castings Bottom Shell offers a warranty of 2 years/500,000 km and a designed lifespan over 7 years or 5 million cycles—validated by 3rd party fatigue and sealing tests.

- Typical Delivery Cycle: Standard motor housing (Bottom Shell) sampling within 21 days, batch delivery 30–40 days, expedited service available.

- Warranty Commitment: 2 years or 500,000 km against leakage, warping, and manufacturing defects.

- Support Offerings: Free design consultation, technical support (24/7 online), and failure analysis for automotive and industrial OEMs globally.