Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Choosing the Right Pipe Cap Fittings for Your Plumbing Needs

Understanding Pipe Cap Fittings A Comprehensive Guide

Pipe cap fittings are essential components in various plumbing and industrial applications. They serve the crucial purpose of sealing the ends of pipes, ensuring that no fluid or gas escapes. This article will delve into the different types, materials, applications, and installation considerations associated with pipe cap fittings.

What is a Pipe Cap?

A pipe cap is a type of fitting used to close off the open ends of a pipe. It is primarily used in various systems to prevent the escape of fluids or gases and to protect the internal surfaces of the pipes from debris or environmental factors. Pipe caps are available in various shapes, sizes, and materials, making them versatile enough for different applications.

Types of Pipe Caps

1. End Caps These are designed to fit snugly over the end of a pipe, effectively sealing it off. They can be threaded or plain, depending on the type of pipe they are used with.

2. Reducing Caps These caps have a larger base that connects to a wider pipe, tapering down to fit a smaller pipe. They are used for transitioning from a larger diameter pipe to a smaller one seamlessly.

3. Square Caps Primarily used for square or rectangular duct systems, these caps are used to seal the ends of ductwork.

4. Seamless Caps Made from solid materials without welds or joints, seamless caps provide a more robust seal and are often used in high-pressure systems.

Materials Used in Pipe Caps

The choice of material for pipe caps depends largely on the application and the fluid or gas being contained. Common materials include

- PVC (Polyvinyl Chloride) Lightweight and resistant to corrosion, PVC caps are ideal for water lines and chemical systems. - Copper Often used in plumbing, copper caps are durable and provide excellent resistance to heat. They are typically found in residential and commercial gaskets.

- Stainless Steel Corrosion-resistant and suitable for high-pressure applications, stainless steel caps are used in industries like oil and gas or food and beverage processing.

- Cast Iron Known for its durability and strength, cast iron caps are commonly used in sewage and drainage applications.

Applications of Pipe Caps

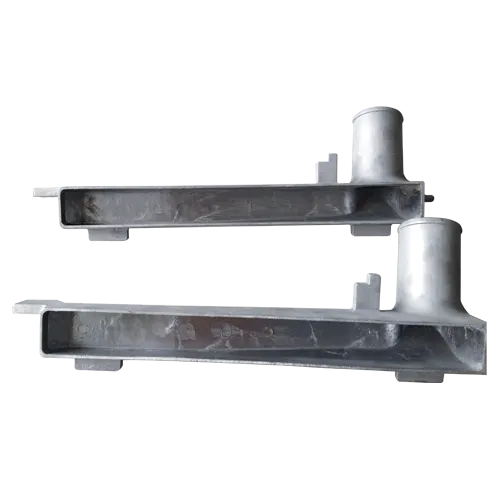

pipe cap fitting

Pipe caps are employed in a variety of industries

. Here are some common applications- Plumbing In residential and commercial plumbing systems, caps seal off unused pipe sections or end connections.

- Construction During building projects, pipe caps are used to secure temporarily unused pipes until they are needed.

- Industrial Manufacturing and processing plants utilize pipe caps in systems that transport various fluids under pressure.

- Oil and Gas In the extraction and refining processes, pipe caps are critical in preventing leaks and protecting the integrity of the piping systems.

Installation Considerations

Installing pipe caps requires careful attention to ensure a proper seal and avoid potential leaks. Here are some tips

1. Cleaning the Pipe Ends Before capping, the ends of the pipes should be cleaned to remove any debris, rust, or old sealant to promote a better fit.

2. Choosing the Right Size Always ensure that the cap matches the diameter of the pipe. Using an incorrect size can lead to ineffective sealing.

3. Application of Thread Sealant For threaded caps, applying a thread sealant can help ensure that the connection is watertight or airtight.

4. Torque Specifications Following manufacturer's guidelines for torque can help avoid damage to the fitting or pipe during installation.

5. Regular Inspections Periodically checking capped pipes for signs of wear or leaks can help maintain the integrity of the system.

Conclusion

Pipe cap fittings are fundamental components that play a significant role in various piping systems across multiple industries. By understanding their types, materials, applications, and installation considerations, you can make informed decisions when selecting the right pipe caps for your needs. Whether you are working on a plumbing project or managing an industrial application, recognizing the importance of these fittings will help ensure the safety and efficiency of your fluid transport systems.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025