Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Different Techniques in Metal Casting for Enhanced Production Efficiency and Quality

Metal Casting Techniques A Comprehensive Guide

Metal casting is a pivotal process in manufacturing that involves pouring molten metal into a mold to create intricate components and structures. This ancient technique, which dates back thousands of years, has evolved and diversified, giving rise to numerous methods suitable for different applications. In this article, we will explore some of the most prominent metal casting techniques, their unique characteristics, applications, and advantages.

1. Sand Casting

Sand casting is the most versatile and widely used casting method. It utilizes a mixture of sand, clay, and water to create molds. The process begins with creating a pattern of the desired object, which is then pressed into the sand to form a mold. Once the pattern is removed, molten metal is poured into the cavity. After cooling, the sand mold is broken apart to retrieve the casting.

Advantages - Cost-effective for small production runs. - Capable of producing large and complex shapes. - Suitable for various metals, including iron, aluminum, and bronze.

Applications Sand casting is commonly employed in automotive parts, industrial machinery, and artistic sculptures.

2. Investment Casting

Investment casting, also known as lost-wax casting, is a precision technique that provides high dimensional accuracy and a smooth surface finish. This method involves creating a wax pattern, which is coated with a ceramic shell to form the mold. Once the ceramic is hardened, the wax is melted and drained away, leaving a cavity for the molten metal.

Advantages - High precision and fine detail. - Excellent surface finish, reducing machining needs. - Ideal for producing small, intricate parts.

Applications Investment casting is widely used in the aerospace, medical devices, and jewelry industries.

3. Die Casting

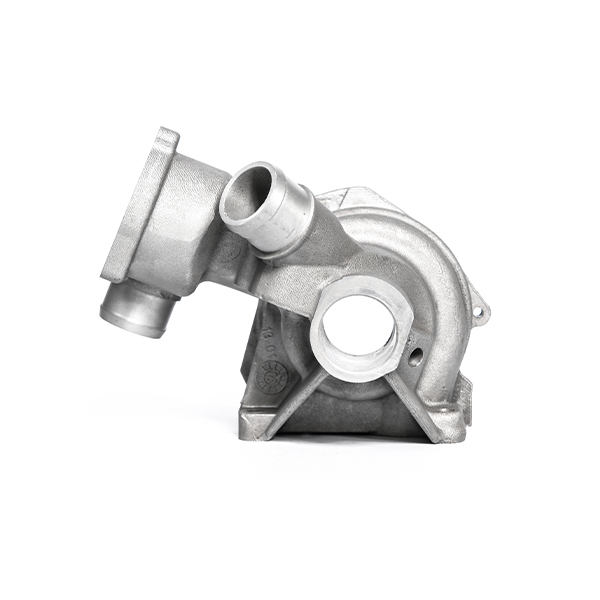

Die casting involves forcing molten metal into a mold under high pressure, which allows for high-speed production of large quantities of parts with good dimensional accuracy. The molds, or dies, are typically made of hard steel, which can withstand the pressures of the molten metal.

metal casting techniques

Advantages - High production rates and low per-part costs. - Excellent surface finish and dimensional consistency. - Minimal machining required for some applications.

Applications Commonly used in the automotive industry for making engine components, transmission housings, and various electronic parts.

4. Lost Foam Casting

Lost foam casting is a relatively modern method where a foam pattern is used instead of a solid one. The foam is coated with a ceramic material to form a mold. When molten metal is poured into the mold, it evaporates the foam, allowing for a precise replica of the pattern to be formed in metal.

Advantages - Excellent dimensional accuracy and surface finish. - No need for cores, reducing complexity. - Ideal for intricate designs.

Applications Often used in manufacturing large industrial components, such as engine blocks and turbos.

5. Continuous Casting

Continuous casting is a modern process where molten metal is poured into a mold, which moves continuously, allowing for the formation of long strands of metal. Once cooled, these strands are cut into desired lengths. This technique is primarily used for producing billets, slabs, or blooms.

Advantages - High efficiency and lower production costs. - Consistent product quality. - Minimal waste due to continuous operation.

Applications Widely used in steelmaking, aluminum production, and other metallurgical processes.

Conclusion

Choosing the right metal casting technique depends on factors such as the complexity of the part, production volume, material properties, and cost considerations. Each method offers unique benefits that cater to specific industrial requirements. With ongoing advancements in technology and materials, metal casting continues to be a vital component in various sectors, contributing to the development of innovative products and solutions. Whether through the age-old sand casting or the high-tech continuous casting, the versatility of metal casting techniques ensures its relevance in the modern manufacturing landscape.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025