Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Efficient Production Techniques for Modern Metal Casting Facilities and Their Innovations

The Importance of Metal Casting in Manufacturing

Metal casting is one of the foundational processes of manufacturing that has been utilized for thousands of years. This technique involves pouring molten metal into a mold to create various shapes and components, making it crucial in industries ranging from automotive to aerospace. The significance of metal casting factories lies not only in their ability to produce high-quality components but also in their contributions to innovation, efficiency, and customization in manufacturing.

The Metal Casting Process

The metal casting process begins with the design of a mold, which can be made from metal, sand, or other composite materials. The choice of mold material depends on the required precision, production volume, and the properties of the metal being used. Common types of casting processes include sand casting, investment casting, die casting, and lost foam casting. Each method has its unique advantages and is selected based on the complexity of the part and the quantity required.

Once the mold is prepared, molten metal—often aluminum, iron, or bronze—is poured into the cavity. As the metal cools, it solidifies and takes on the shape of the mold. After cooling, the mold is removed, revealing the cast part, which may require further finishing processes like machining, polishing, or heat treatment to achieve the desired specifications.

Advantages of Metal Casting

One of the primary advantages of metal casting is its ability to produce complex shapes that would be difficult or impossible to achieve through other manufacturing methods. This capability allows designers more freedom and creativity when designing components, as intricate geometries can be crafted with ease. Moreover, casting can accommodate a wide variety of metal types, providing manufacturers with great flexibility to choose materials that best suit their needs—whether for strength, weight, or resistance to corrosion and heat.

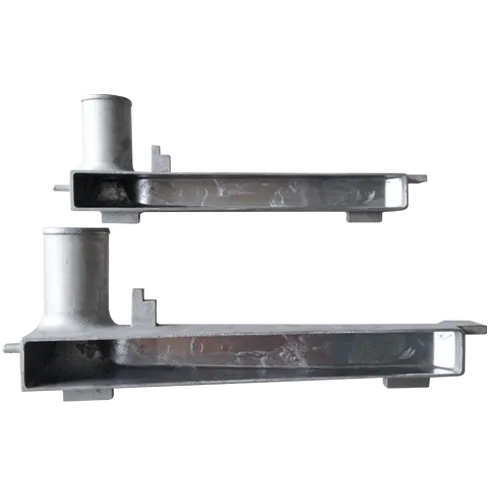

metal casting factory

In addition, metal casting is often more cost-effective for large production runs compared to other methods. Once a mold is created, it can be used repeatedly, leading to economies of scale. This efficiency is particularly important in industries with high demand for specific parts, as it can significantly reduce manufacturing time and labor costs.

Innovation and Sustainability in Metal Casting

As technology advances, metal casting factories are implementing innovative techniques to enhance efficiency and reduce waste. Automation and computer-aided design (CAD) have streamlined the design and production processes, allowing for quicker turnaround times and high precision. Additionally, the rise of additive manufacturing and 3D printing technologies is being integrated into traditional casting methods, further improving capabilities and reducing materials waste.

Sustainability is another growing focus within the metal casting industry. Many factories are adopting practices to recycle scrap metal and use environmentally friendly materials. Green sand casting, for example, utilizes sand that can be reused, minimizing waste. Moreover, the industry is increasingly looking toward energy-efficient furnaces and processes to reduce their carbon footprint.

Conclusion

Metal casting factories play a vital role in modern manufacturing by enabling the production of complex, high-quality components at competitive costs. As industries evolve and the demand for innovative solutions grows, metal casting will continue to adapt through technological advancements and sustainable practices. The intricate relationship between metal casting and manufacturing highlights the importance of this age-old technique in the advancement of modern technology and industry. As we look to the future, metal casting will undoubtedly remain a cornerstone of manufacturing, bridging the gap between classic techniques and new-age innovations.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025