Mobile:+86-311-808-126-83

Email:info@ydcastings.com

low pressure casting

Low Pressure Casting An Efficient Solution in Metal Manufacturing

Low pressure casting, also known as die casting, is a widely utilized manufacturing process that involves the use of a controlled low-pressure environment to inject molten metal into a mold. This technique is particularly favored in industries that require high precision and excellent surface finishes in metal components. It is essential to understand the process, benefits, and applications of low pressure casting to appreciate its significance in modern metalworking.

The Process of Low Pressure Casting

The low pressure casting process begins with the preparation of a mold, typically made of steel or other high-temperature resistant materials. The mold is designed to accommodate the specific shape and dimensions of the desired metal component. Once the mold is ready, molten metal – which can include aluminum, zinc, and magnesium alloys – is introduced into a chamber at low pressure, usually ranging from 0.5 to 1.0 bars.

The low-pressure environment is created by using a gas-filled chamber or a vacuum system that pushes the molten metal into the mold. This controlled injection allows the metal to flow smoothly, reducing turbulence that could lead to defects. As the metal fills the mold cavity, it cools and solidifies, taking the shape of the mold. Finally, once the metal has cooled sufficiently, the mold is opened, and the finished part is removed.

Advantages of Low Pressure Casting

One of the primary advantages of low pressure casting is the quality of the finished product

. The low-pressure injection method results in fewer porosities and inclusions compared to traditional casting methods. As a result, components manufactured using this technique exhibit enhanced mechanical properties and durability, making them suitable for critical applications, especially in the automotive and aerospace industries.low pressure casting

Another significant benefit is the ability to produce intricate designs with high precision. The controlled flow of molten metal allows for the creation of complex geometries that would be challenging to achieve with other casting techniques. This capability makes low pressure casting an excellent option for producing lightweight components without sacrificing strength.

Low pressure casting also demonstrates superior material utilization. The process generates minimal scrap material, and the ability to recycle leftover metal enhances its eco-friendliness. Additionally, the production cycle is faster, leading to increased productivity and cost-effectiveness. Manufacturers can produce higher volumes of parts in a shorter time frame, which is particularly important in today's competitive markets.

Applications in Various Industries

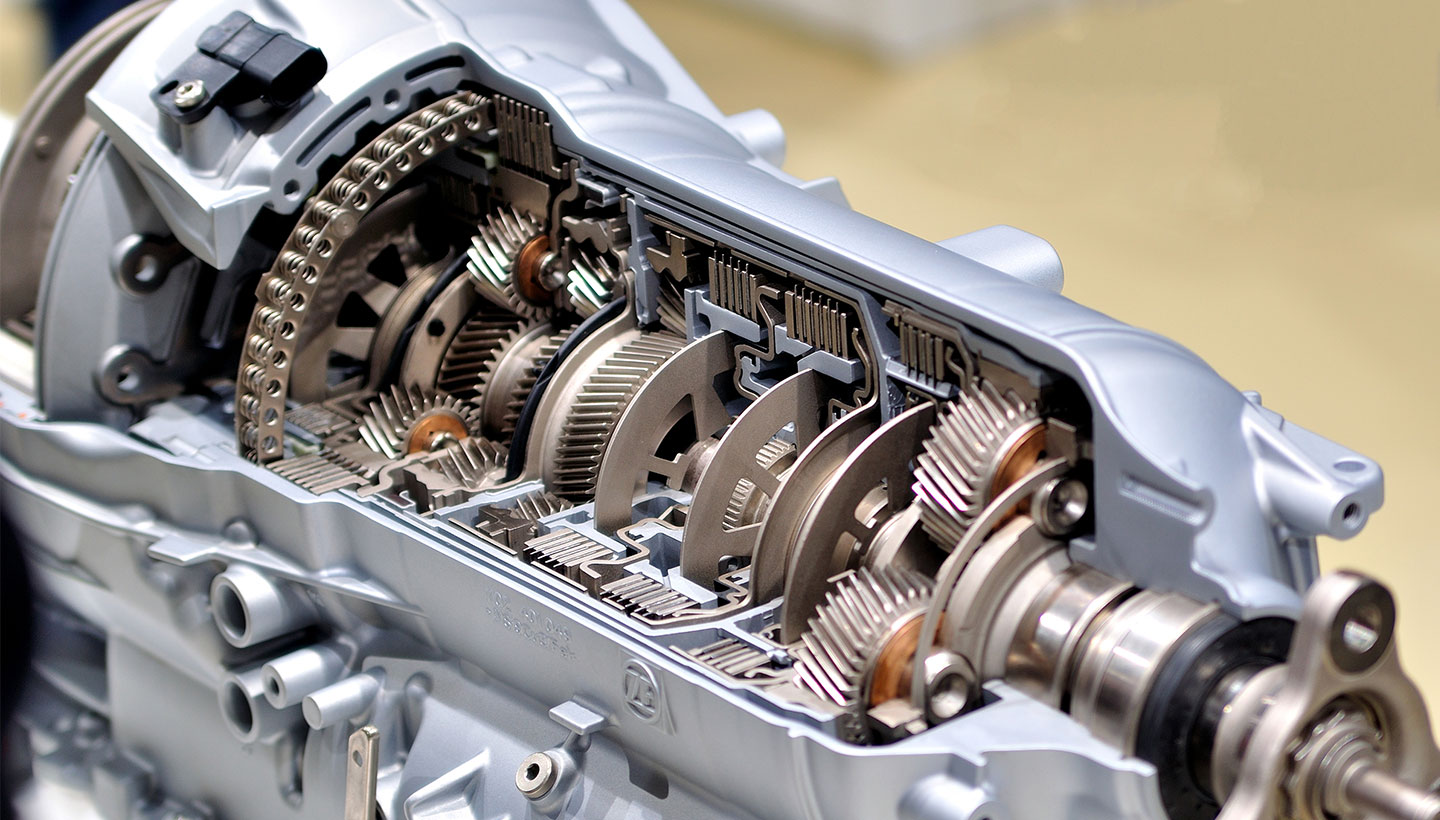

Low pressure casting is utilized across various industries due to its versatility. In the automotive sector, it is commonly used for manufacturing engine blocks, transmission cases, and other critical components that require high strength and lightweight characteristics. The aerospace industry also benefits from low pressure casting, producing parts such as landing gear components and structural elements that must meet stringent safety and performance standards.

Furthermore, this casting technique is applied in the production of medical devices, appliances, and consumer electronics, underscoring its adaptability in meeting diverse engineering demands.

Conclusion

Low pressure casting represents a pivotal advancement in metal manufacturing, combining precision, efficiency, and quality. With its ability to produce complex shapes while minimizing production costs and waste, it stands out as a preferred method in various industries. As technology continues to evolve, low pressure casting is expected to play an even more significant role in driving innovation and excellence in metal component manufacturing. Understanding and embracing this technique will undoubtedly benefit manufacturers seeking to enhance their production capabilities and meet the growing demands of the market.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025