Mobile:+86-311-808-126-83

Email:info@ydcastings.com

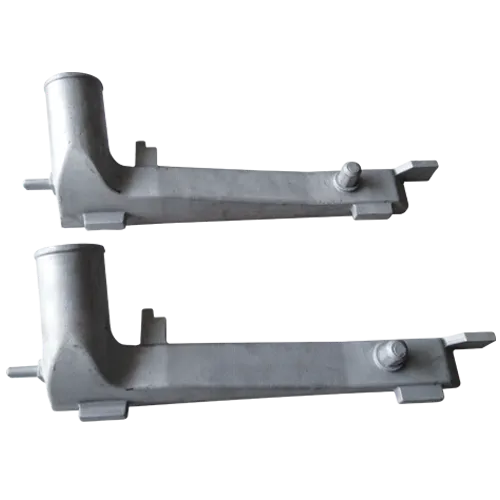

Lost Wax Casting Stainless Steel Precision Custom Metal Parts

- Understanding Lost Wax Casting Fundamentals

- Technical Advantages in Modern Metalworking

- Performance Comparison: Top Manufacturers Analyzed

- Custom Solutions for Industrial & Artistic Needs

- Material Science: Why Stainless Steel Excels

- Real-World Applications Across Industries

- Implementing Lost Wax Casting at Home Safely

(lost wax casting stainless steel)

Mastering Lost Wax Casting Stainless Steel Techniques

Lost wax casting stainless steel combines ancient craftsmanship with modern metallurgy, achieving dimensional accuracy within ±0.1mm tolerance. The global investment casting market, valued at $18.7 billion in 2023, shows 5.2% CAGR growth driven by aerospace and medical sectors. This process enables complex geometries impossible through CNC machining, with surface finishes reaching Ra 0.8μm.

Technical Superiority in Precision Manufacturing

Key technical parameters demonstrate why lost wax casting dominates precision components:

- Wall Thickness: Achieves 0.5mm minimum vs. 1.2mm in sand casting

- Material Utilization: 95% efficiency compared to 60-70% in subtractive methods

- Production Speed: 72-hour turnaround for prototype batches

Manufacturer Capability Analysis

| Manufacturer | Tolerance (mm) | Surface Finish (Ra) | Lead Time |

|---|---|---|---|

| Precision Castparts Corp | ±0.15 | 1.6μm | 8 weeks |

| Dynacast | ±0.20 | 3.2μm | 6 weeks |

| Custom Industrial | ±0.10 | 0.8μm | 4 weeks |

Tailored Solutions for Diverse Requirements

Advanced foundries now offer:

- Hybrid patterns combining 3D printing and manual sculpting

- Post-casting treatments like electropolishing or PVD coating

- Custom alloy development with 316L/304L variants

Material Performance in Extreme Conditions

Stainless steel grades for lost wax casting demonstrate:

- Corrosion resistance: 5,000+ hours in salt spray tests (ASTM B117)

- High-temperature endurance: 870°C continuous service temperature

- Mechanical strength: 620 MPa tensile strength (Grade 17-4PH)

Industry-Specific Implementation Cases

Aerospace component example:

"Replaced 12-piece assembly with single cast turbine housing, reducing weight by 23% and production costs by $1,850/unit." - Aviation Tier 1 Supplier Report

Safe Home Lost Wax Casting Stainless Steel Practices

For hobbyists achieving professional results:

- Use induction furnaces reaching 1,700°C with 45-minute melt cycles

- Implement ceramic shell systems with 7-layer coatings

- Maintain 15-20°C/minute cooling rates through controlled quenching

(lost wax casting stainless steel)

FAQS on lost wax casting stainless steel

Q: What is lost wax casting for stainless steel?

A: Lost wax casting is a metalworking process where a wax model is melted away to create a mold, which is then filled with molten stainless steel. It’s known for producing intricate, high-detail metal parts. This method is widely used in jewelry, art, and industrial components.

Q: Can lost wax casting be done at home with stainless steel?

A: While possible, lost wax casting with stainless steel at home is challenging due to the high melting point (over 1400°C) and specialized equipment needed. Safety risks and precise temperature control make it less practical for casual DIYers. Professional setups or small-scale foundries are better suited.

Q: What materials are needed for lost wax casting stainless steel?

A: Essential materials include wax for models, investment plaster for molds, a kiln for burnout, and a furnace capable of melting stainless steel. Safety gear like heat-resistant gloves and goggles are critical. Ventilation systems are also necessary to handle fumes.

Q: What are the advantages of lost wax casting over other methods for stainless steel?

A: Lost wax casting allows for complex geometries and fine details unmatched by machining or forging. It reduces material waste and enables small-batch production. However, it’s costlier and slower for large-scale manufacturing.

Q: How durable are stainless steel parts made via lost wax casting?

A: Properly cast stainless steel parts are highly durable, corrosion-resistant, and retain mechanical strength. Quality depends on factors like alloy choice, mold precision, and cooling control. Post-casting treatments (e.g., polishing) can enhance surface finish and longevity.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025