Mobile:+86-311-808-126-83

Email:info@ydcastings.com

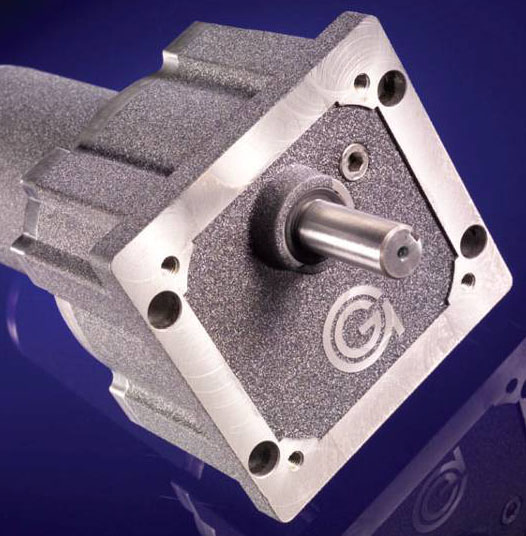

industrial impeller

Industrial Impellers The Heart of Fluid Dynamics

In the expansive world of industrial machinery, certain components play pivotal roles in ensuring efficiency and performance. One such component is the impeller, an integral part of many fluid dynamics applications, particularly in pumps and compressors. The design and function of industrial impellers directly influence the movement of fluids, making them vital to various industries, from water treatment and manufacturing to aerospace and oil refining.

An impeller is essentially a rotating component that transfers energy to a fluid, converting mechanical energy from a motor into kinetic energy in the fluid, causing it to flow. The design of an impeller can vary significantly depending on its application, but common designs include axial, centrifugal, and mixed flow impellers. Each design has its distinct characteristics and operational advantages.

Centrifugal Impellers

Centrifugal impellers are perhaps the most widely used type in industrial applications. They operate by imparting radial acceleration to the fluid, pulling it in at the eye of the impeller and forcing it outward along a spiral path. This type of impeller is particularly effective for applications requiring high pressure and flow rates, such as in water supply systems, HVAC systems, and various manufacturing processes. Their efficiency and ability to handle fluids with particulates make them a preferred choice in many sectors.

Axial Impellers

On the other hand, axial impellers function differently. Instead of pushing the fluid outward, they move it parallel to the impeller shaft. This makes them ideal for applications that require high flow rates but lower pressure, such as in cooling systems and large industrial pumps. Axial flow impellers are often found in diesel engines, hydroelectric generating facilities, and wastewater treatment plants, where substantial volumes of fluid need to be transported efficiently.

Mixed Flow Impellers

industrial impeller

Mixed flow impellers combine characteristics of both centrifugal and axial designs. They can handle higher flow rates while also producing greater pressure. Their versatility makes them suitable for a range of applications. Depending on the specific requirements, mixed flow impellers can be designed to optimize for either characteristic, providing great flexibility for engineers and designers.

Material Considerations and Advances in Technology

The materials used in constructing industrial impellers are crucial for their performance and durability. Common materials include stainless steel, bronze, and various polymers, selected for their corrosive resistance, mechanical strength, and weight properties. Innovations in manufacturing techniques, such as 3D printing and the use of composite materials, have further expanded the potential for impeller design, enabling the creation of complex shapes and improved aerodynamic profiles that enhance efficiency.

The Role of Impeller Design in Efficiency and Sustainability

The design of an impeller significantly impacts energy consumption. An efficient impeller not only reduces operational costs but also diminishes the carbon footprint of industrial operations. In an era where sustainability is at the forefront of industrial development, engineers are increasingly focusing on optimizing impeller designs to improve efficiency and reduce waste. Computational fluid dynamics (CFD) simulations and advanced modeling techniques allow engineers to iterate designs quickly, finding the best configuration for each specific application.

Conclusion

In conclusion, industrial impellers are crucial components that drive fluid dynamics across numerous applications. Understanding their design, functionality, and material considerations is essential for optimizing industrial processes. As technology progresses, the future of impeller design looks promising, with ongoing innovations aimed at enhancing efficiency and sustainability. In a world where energy efficiency is paramount, the industrial impeller stands as a testament to the importance of engineering innovation in solving modern challenges.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025