Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 19, 2025 01:59

Back to list

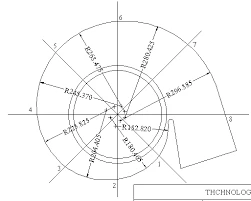

impeller paddle

Selecting the right impeller paddle for your industrial mixing processes is pivotal to achieving optimal results. This sophisticated piece of equipment ensures that mixtures are homogeneous, efficient, and cost-effective. In this guide, we will explore the intricate features of impeller paddles, offering insights drawn from years of experience and expertise, anchored by authoritative knowledge that you can trust.

The trustworthiness of your mixing equipment is crucial. Regular maintenance checks and proper calibration ensure longevity and consistent performance. An overlooked but essential aspect is the balance of the impeller paddle. An imbalanced paddle can lead to excessive wear and tear on the mixing motor, potentially leading to costly downtime. Trustworthy equipment suppliers should provide thorough documentation and support for maintenance routines. Furthermore, the adaptation to new technological advancements in impeller paddle design can alleviate operational inefficiencies. For instance, the integration of sensor technology directly onto the paddle can provide real-time data on the mixing environment, such as temperature and viscosity changes, allowing for on-the-fly adjustments to parameters and improving overall process control. In conclusion, the choice of an impeller paddle is a critical decision that influences the success of your mixing processes. Relying on expert advice, prioritizing precision engineering, and choosing trusted materials and suppliers will ensure that your equipment performs reliably over time. For optimal results, always consider the unique requirements of your operation and stay abreast of technological advancements that can offer added value to your processes. In implementing these best practices and with a willingness to innovate, your use of impeller paddles can be a decisive factor in achieving success within your industry.

The trustworthiness of your mixing equipment is crucial. Regular maintenance checks and proper calibration ensure longevity and consistent performance. An overlooked but essential aspect is the balance of the impeller paddle. An imbalanced paddle can lead to excessive wear and tear on the mixing motor, potentially leading to costly downtime. Trustworthy equipment suppliers should provide thorough documentation and support for maintenance routines. Furthermore, the adaptation to new technological advancements in impeller paddle design can alleviate operational inefficiencies. For instance, the integration of sensor technology directly onto the paddle can provide real-time data on the mixing environment, such as temperature and viscosity changes, allowing for on-the-fly adjustments to parameters and improving overall process control. In conclusion, the choice of an impeller paddle is a critical decision that influences the success of your mixing processes. Relying on expert advice, prioritizing precision engineering, and choosing trusted materials and suppliers will ensure that your equipment performs reliably over time. For optimal results, always consider the unique requirements of your operation and stay abreast of technological advancements that can offer added value to your processes. In implementing these best practices and with a willingness to innovate, your use of impeller paddles can be a decisive factor in achieving success within your industry.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS