Mobile:+86-311-808-126-83

Email:info@ydcastings.com

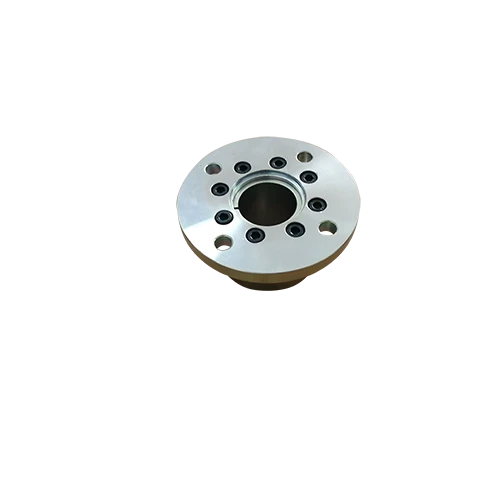

impeller in centrifugal compressor

The Role of Impellers in Centrifugal Compressors

Centrifugal compressors are widely used in various industrial applications, including power generation, refrigeration, and air conditioning systems. At the heart of these machines lies the impeller, a crucial component that significantly influences the compressor's performance and efficiency. Understanding the structure and function of impellers in centrifugal compressors is essential for optimizing their operation.

The Role of Impellers in Centrifugal Compressors

Typically, impellers are designed with either open or closed configurations. Open impellers have blades that are not enclosed by a shroud, allowing for easy cleaning and maintenance but generally resulting in lower efficiency. Closed impellers, on the other hand, have a shroud that encloses the blades, providing better performance and balance but may require more complex manufacturing processes.

impeller in centrifugal compressor

The performance of the impeller is influenced by various factors, including flow rate, rotational speed, and the properties of the gas being compressed. High rotational speeds can lead to higher pressure ratios, but they also increase the risk of cavitation—an instability that occurs when vapor bubbles form and collapse within the fluid flow, potentially causing damage to the impeller. To mitigate these risks, engineers must carefully consider the impeller design, ensuring it operates within safe limits while maximizing efficiency.

Moreover, advancements in materials science have led to the development of stronger, lighter materials that enhance the durability of impellers. Modern impellers are often made from alloys or composites that can withstand high temperatures and pressures, further improving the reliability and lifespan of centrifugal compressors.

In conclusion, the impeller is a vital component in centrifugal compressors, directly affecting their efficiency and performance. A well-designed impeller can greatly enhance the compressor's capability to move gases at high pressure and flow rates. As technology continues to advance, the evolution of impeller design will undoubtedly contribute to more efficient and robust centrifugal compressors, meeting the growing demands of various industries while minimizing energy consumption. Understanding the intricacies of impeller function is essential for engineers and industry professionals aiming to optimize compressor performance in today's competitive landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025