Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

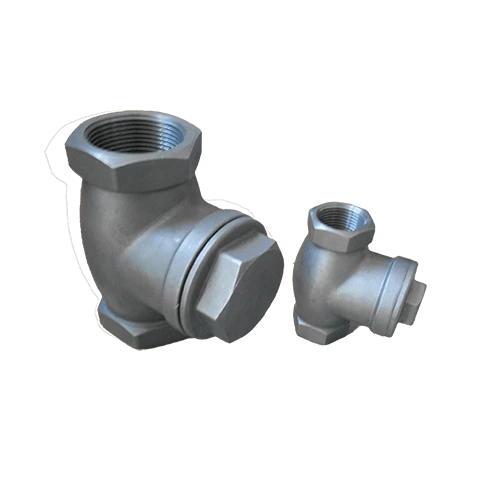

High-Quality Valve Body Castings for Durable Performance

Official Website: https://www.ydcastings.com

Phone: +86-311-808-126-83

E-mail: info@ydcastings.com

WhatsApp/Cell: +86 19333736198

Address: No.563 Xinhua Road, Shijiazhuang City, Hebei Province, P.R. China. 050051.

Name: Valve body

Material: Stainless steel 304, 316L

Process: Precision Casting

Specification: 0.8-20kg

Product URL: Click here

Industry Trends and Market Outlook for Valve Body Technology

In the rapidly evolving industrial sector, the demand for high-performance valve body components has surged, driven by stricter energy efficiency regulations, increasing process automation, and the rising need for reliable flow control. Valve body castings, including stainless steel 304, 316L precision cast variants, and related products like cast iron valve box cover, cast iron water valve cover, and water valve cover cast iron, are essential for oil & gas, waterworks, chemical, and municipal pipeline systems (Valve World Industry Report).

- Global Valve Market 2024-2030: Projected CAGR of 4.5%, with the valve body segment growing steadily due to its critical role in flow regulation (Market Research).

- Technological Advances: Emphasis on corrosion-resistant castings, advanced sealing, and smart monitoring integration.

- Application Boom: Water distribution networks are demanding advanced cast iron valve box covers and water valve cover cast iron for infrastructure upgrades.

Key Parameters of Valve Body (Table Overview)

| Parameter | Typical Range / Value | Industry Standard |

|---|---|---|

| Material | Stainless Steel 304, 316L, Cast Iron, Bronze | ASTM A351, ISO 9001, EN 10213 |

| Process | Precision Casting, Sand Casting, Forged | ISO 8062-3:2007 |

| Weight Range | 0.8 - 20kg | Customizable |

| Surface Treatment | Pickling, Passivation, Shot Blasting | NACE MR0175 |

| Applicable Media | Water, Oil, Steam, Gas | API 598, EN 12266-1 |

| Temperature Range | -40°C to 220°C | Material Dependent |

| Pressure Class | PN10-PN40, Class 150-300 | ANSI B16.34 |

Comprehensive Application Scenarios and Industry Use Cases

- Municipal Waterworks: Installation of cast iron valve box covers ensures the safety of underground water control valves, critical for city water supply.

- Oil & Gas Pipelines: Corrosion-resistant valve body castings maintain system integrity in extreme conditions and corrosive environments.

- Industrial Automation: High-precision valve body parts meet the automation industry's need for seamless process control.

- Chemical Processing: Stainless steel 316L valve body castings protect against aggressive chemicals; conforming to API and EN standards.

- Fire Protection Systems: Dependable cast iron water valve covers secure hydrant and sprinkler network valves.

- Irrigation & Agriculture: Water valve cover cast iron solutions offer durability in buried networks.

- HVAC & Energy Plants: Reliable flow control with customized valve bodies for steam, chilled/heated water, and compressed air systems.

Technical Authority & Industry Best Practices

According to Valve Casting Guidelines (Forging Industry Association), the performance, longevity, and reliability of any hydraulic/pneumatic system derive directly from precise engineering of the valve body. Integrating superior valve body castings with advanced surface finishes drastically reduces system downtime and leaks.

Frequently Asked Technical Questions (Valve Body FAQ)

Q1: What is the most common material used for a valve body in waterworks?

A: While traditional waterworks utilize cast iron valve box cover and water valve cover cast iron, modern networks increasingly adopt stainless steel 304 and 316L for enhanced corrosion resistance and long service life (Valve Magazine).

Q2: What specification standards are applicable for valve body castings?

A: Principal standards include ASTM A351 for stainless steel, ISO 9001 for quality management, and EN 10213 for pressure equipment.

Q3: How does casting process affect valve body performance?

A: Precision casting produces denser, more dimensionally accurate valve bodies compared to sand casting, ensuring tighter sealing and higher fatigue life (ScienceDirect).

Q4: What weight range can a customized valve body be supplied in?

A: Castings are typically available between 0.8kg and 20kg, depending on application. Larger sizes are engineered upon request by Hebei Yuanda Trade Co., Ltd..

Q5: What installation standards are relevant for cast iron valve box cover?

A: EN 124 (for access covers and grates) and AWWA C502 (hydrant valves) are prevalent, with compliance ensuring safety and compatibility.

Q6: How is corrosion resistance optimized in valve body manufacturing?

A: Through material selection (304/316L), surface treatments like pickling/passivation, and advanced sealing. NACE MR0175 compliance is also essential for oil & gas applications.

Q7: Can valve body designs be adapted for specific fluids or gases?

A: Absolutely. Designs are tailored for water, oil, gas, steam, and aggressive chemicals, with O-ring and seat materials customized per application requirements.

Why Choose Hebei Yuanda Trade Co., Ltd. for Valve Body & Cast Iron Solutions?

- Proven expertise in precision casting stainless steel and cast iron valve bodies.

- Comprehensive material certification and global standard compliance.

- Robust quality control from design, pattern making, melting, pouring, and finishing to inspection (including radiography, UT/MPI, and pressure testing).

- Professional engineering support for custom valve body or cast iron valve box cover projects.

- Responsive service and fast delivery to global markets.

- Trusted by major utilities, contractors, and OEMs worldwide.

Conclusion: The Future of Valve Body Engineering & Industry References

As infrastructure develops and as the world turns to smart water and industrial automation, the importance of robust, precisely engineered valve body solutions—be it for cast iron valve box covers or innovative stainless steel castings—will only grow.

For best-in-class valve body solutions, from design to delivery, choose Welcome To Hebei Yuanda Trade Co., Ltd..

Phone: +86-311-808-126-83 | Email: info@ydcastings.com | Mobile: +86 19333736198

Address: No.563 Xinhua Road, Shijiazhuang City, Hebei Province, P.R. China. 050051.

References:

Valve World Industry Report |

Valve Market Research |

Forging Industry Association: Valve Casting Guidelines |

Valve Magazine |

ScienceDirect: Valve Bodies