Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Mar . 05, 2025 03:05

Back to list

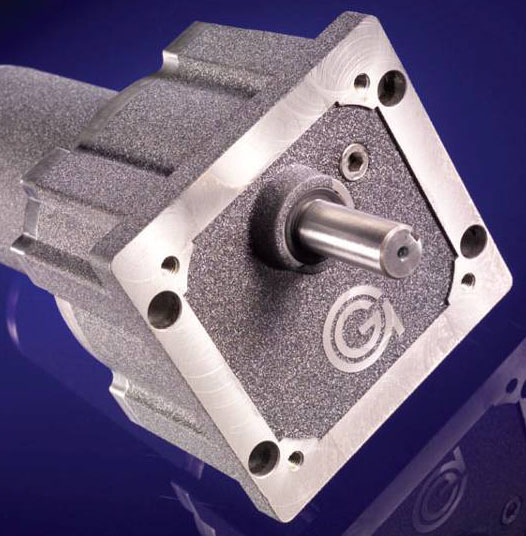

gearbox housing

In the intricate world of mechanical engineering, the gearbox shell stands as a fundamental component within a wide range of machinery, playing a pivotal role in housing and protecting the gearbox's internal components. A comprehensive understanding of the gearbox shell, coupled with genuine expertise, is crucial for optimized performance and longevity of machinery. This expertise translates into significant competitive advantages in industries reliant on precise mechanical systems.

Trustworthiness in the gearbox industry is often established through adherence to rigorous manufacturing standards and testing protocols. Quality assurance processes, such as non-destructive testing and precise machining, ensure that each gearbox shell upholds its structural integrity under operational stresses. Reputable manufacturers invest in advanced CNC machinery and employ experienced technicians to deliver consistent quality that customers can rely on. Authoritativeness in the industry is reflected in ongoing research and development efforts aimed at advancing gearbox technology. Collaborative projects with leading universities and research institutions help push the boundaries of what modern gearbox shells can achieve. This commitment to innovation not only advances the capabilities of mechanical systems but also opens new possibilities for applications across different industries. Lastly, trustworthiness is further cemented through customer education and transparent communication. Companies that provide detailed information on the maintenance and operation of gearbox shells empower users to maximize their equipment's lifespan. Access to comprehensive resources, such as guides on preventative maintenance and channels for technical support, builds confidence in users and fosters long-term relationships. In summation, the gearbox shell is a testament to engineering precision and innovation. Its role in machinery is fundamental, with its performance directly influencing the operational success of the systems it is part of. A deep understanding, backed by real-world experience and technical expertise, is essential for optimizing its use. Expertise ensures it is designed with precision, trust is gained through consistent quality and transparency, and authority is maintained through continual innovation. By focusing on these core elements, the significance of the gearbox shell is illuminated, ensuring machinery operates at peak efficiency and reliability.

Trustworthiness in the gearbox industry is often established through adherence to rigorous manufacturing standards and testing protocols. Quality assurance processes, such as non-destructive testing and precise machining, ensure that each gearbox shell upholds its structural integrity under operational stresses. Reputable manufacturers invest in advanced CNC machinery and employ experienced technicians to deliver consistent quality that customers can rely on. Authoritativeness in the industry is reflected in ongoing research and development efforts aimed at advancing gearbox technology. Collaborative projects with leading universities and research institutions help push the boundaries of what modern gearbox shells can achieve. This commitment to innovation not only advances the capabilities of mechanical systems but also opens new possibilities for applications across different industries. Lastly, trustworthiness is further cemented through customer education and transparent communication. Companies that provide detailed information on the maintenance and operation of gearbox shells empower users to maximize their equipment's lifespan. Access to comprehensive resources, such as guides on preventative maintenance and channels for technical support, builds confidence in users and fosters long-term relationships. In summation, the gearbox shell is a testament to engineering precision and innovation. Its role in machinery is fundamental, with its performance directly influencing the operational success of the systems it is part of. A deep understanding, backed by real-world experience and technical expertise, is essential for optimizing its use. Expertise ensures it is designed with precision, trust is gained through consistent quality and transparency, and authority is maintained through continual innovation. By focusing on these core elements, the significance of the gearbox shell is illuminated, ensuring machinery operates at peak efficiency and reliability.

Next:

Latest news

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025

Related PRODUCTS