Mobile:+86-311-808-126-83

Email:info@ydcastings.com

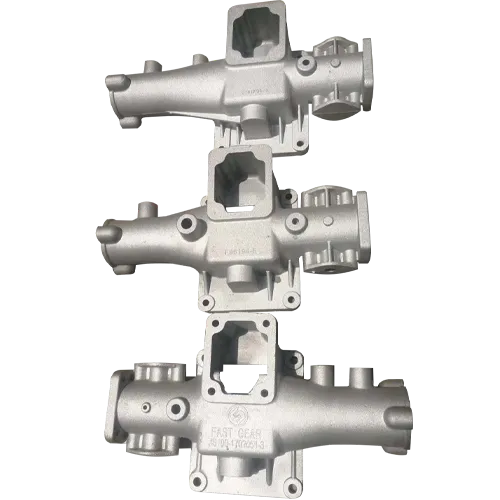

female threaded end cap

Understanding Female Threaded End Caps Applications and Benefits

In various industries, the need for effective fluid control and containment has led to the development of numerous components, one of which is the female threaded end cap. This versatile product plays a crucial role in plumbing, manufacturing, and construction, providing not only a secure sealing solution but also an efficient method for connecting and disconnecting piping systems.

What is a Female Threaded End Cap?

A female threaded end cap is a type of fitting designed to close the end of a pipe or a tube. It features internal threads that allow it to be screwed onto the external threads of a pipe, creating a leak-proof seal. These caps are typically made from various materials, including PVC, brass, stainless steel, and other alloys, enabling their use in different environments— from residential plumbing systems to industrial piping applications.

Applications of Female Threaded End Caps

1. Plumbing Systems In residential and commercial plumbing, female threaded end caps are used to terminate water pipes and prevent leaks. They are essential in ensuring that potable water remains uncontaminated and in maintaining the overall integrity of plumbing systems.

2. Manufacturing In manufacturing processes, fluids—whether they are liquids or gases—often need to be contained securely. Female threaded end caps are used in pressure vessels, tanks, and piping systems to ensure that substances do not escape, thereby enhancing safety and efficiency.

3. Construction These fittings are also common in construction sites where temporary piping systems might be required. They can be used to cap off pipes that are not in use, preventing debris from entering the system while allowing for future expansion or modification.

female threaded end cap

4. Automotive and Aerospace In the automotive industry, female threaded end caps are often used in cooling systems and fuel lines, ensuring that fluids are contained within the system, thereby preventing leaks that could lead to hazardous situations. The aerospace sector utilizes these fittings in fuel systems, hydraulic systems, and pneumatic applications to ensure optimal performance and safety.

Benefits of Using Female Threaded End Caps

The advantages of female threaded end caps are abundant. Firstly, they provide a robust barrier against leaks, ensuring that systems function as intended. The ease of installation and removal allows for quick maintenance and adjustments—an essential factor in industries where time is critical.

Additionally, these caps are available in a variety of sizes and materials, offering flexibility in application. Whether dealing with high-pressure systems or corrosive substances, there is a female threaded end cap suitable for the job.

Finally, the cost-effectiveness of female threaded end caps makes them an attractive choice for many businesses. Their durability and reliability lead to lower maintenance costs and greater longevity, ensuring that investments in piping infrastructure pay off over time.

Conclusion

In conclusion, female threaded end caps are vital components in a wide range of industries, providing essential sealing solutions that enhance safety, efficiency, and performance. Understanding their applications and benefits is crucial for anyone involved in the selection and maintenance of piping systems, making them a key element in effective fluid control and management.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025