Mobile:+86-311-808-126-83

Email:info@ydcastings.com

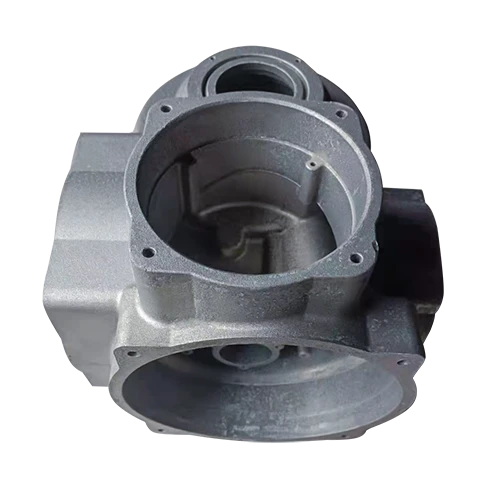

engine exhaust manifold casting

Engine Exhaust Manifold Casting An Overview

The engine exhaust manifold is a crucial component of an internal combustion engine, responsible for directing exhaust gases from the engine cylinders to the exhaust system. The efficiency and durability of the exhaust manifold can significantly affect vehicle performance, emissions, and overall engine efficiency. One of the primary methods of producing exhaust manifolds is through casting, a manufacturing process widely used in the automotive industry.

Casting involves pouring molten metal into a mold, where it cools and solidifies into the desired shape. For exhaust manifolds, cast iron and certain alloys are commonly used due to their excellent heat resistance and strength. The casting process allows for complex geometries that can accommodate the specific design requirements of different engine configurations.

The casting process for exhaust manifolds typically involves several key steps. First, a pattern is created, usually made from materials such as metal or wood. This pattern is used to form a mold, which is often made from sand or metal. After the mold is prepared, molten metal is poured into it, filling the cavity created by the pattern. Once the metal has cooled and solidified, the mold is removed, and the casting is cleaned and finished.

engine exhaust manifold casting

One of the significant advantages of casting exhaust manifolds is the ability to produce high-quality, durable components that can withstand the harsh conditions of engine operation. Cast iron manifolds are known for their resistance to thermal fatigue and their ability to absorb vibrations, which reduces noise and enhances comfort. Moreover, the casting process allows for more intricate designs, which can optimize airflow and improve engine performance.

However, casting also comes with its own set of challenges. The process can introduce defects such as porosity, which can weaken the manifold and lead to potential failures. To combat these issues, manufacturers often implement stringent quality control measures during production, including inspections and testing of the castings.

In conclusion, engine exhaust manifold casting is a vital manufacturing process that plays a pivotal role in automotive performance and emissions control. With advancements in casting technology and materials, manufacturers continue to develop more efficient and durable exhaust manifolds, contributing to the overall improvement of modern engines. As the automotive industry moves toward more sustainable practices, innovations in casting will remain crucial in meeting future demands for performance, efficiency, and environmental responsibility.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025