Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design Features and Benefits of Double Suction Impellers for Efficient Fluid Handling

Understanding Double Suction Impellers Design and Applications

Double suction impellers are essential components widely used in various centrifugal pumps, particularly in applications requiring a high flow rate and efficiency. These impellers are designed to draw fluid from both sides, minimizing axial thrust and providing a balanced operation. This unique design holds significant importance in both industrial and municipal applications, contributing to improved hydraulic performance and longevity of pump systems.

The design of a double suction impeller features two parallel suction ports that allow fluid to enter from both sides of the impeller. This dual-entry system means that the impeller can handle larger volumes of liquid with less energy input compared to traditional single suction designs. This efficiency makes double suction impellers particularly favorable in heavy-duty pumps used for water supply systems, boiler feed water applications, and in various industrial sectors such as oil and gas, chemicals, and power generation.

One of the most noteworthy advantages of double suction impellers is their ability to minimize axial loads. In single suction impellers, the fluid enters from one side, resulting in significant axial thrust. This imbalance can lead to increased wear and tear on the pump components and often requires additional support mechanisms, ultimately raising operational costs. In contrast, the double suction arrangement naturally balances these forces, allowing for a more stable operation and extending the service life of the pump system.

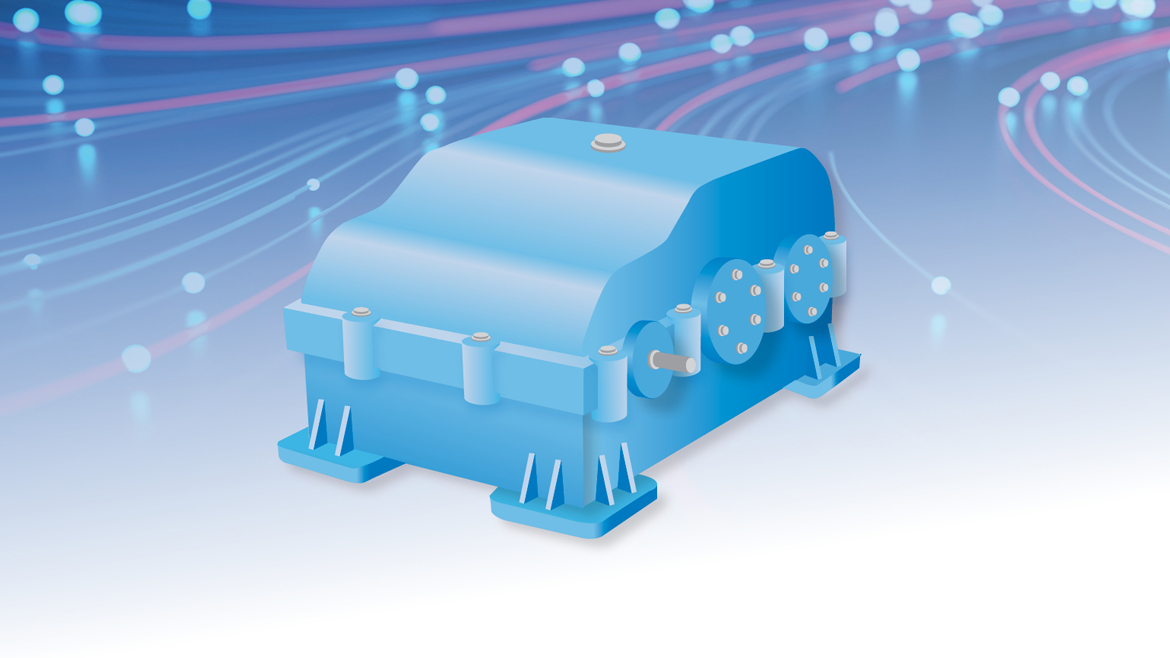

double suction impeller

Moreover, double suction impellers are highly customizable. Engineers can design them with different blade geometries, materials, and dimensions to cater to specific applications. This versatility is valuable in industries where fluid characteristics, such as viscosity or temperature, may vary widely. By tailoring the impeller design, manufacturers can optimize performance and ensure efficient fluid handling.

However, it is essential to consider the limitations as well. While double suction impellers excel in high-flow applications, they may not be suitable for low-flow conditions due to their design complexity and potential for cavitation at low speeds. Therefore, a thorough understanding of the application's requirements is crucial before selecting a pump with a double suction impeller.

In summary, double suction impellers represent an innovative solution in centrifugal pump technology, characterized by their dual suction capability and minimized axial thrust. They are widely employed in high-flow applications across various industries due to their efficiency, reduced wear, and stability. As technology advances, ongoing research and development will likely lead to further enhancements in impeller design and performance, solidifying their place as a key component in modern fluid handling systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025