Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Fév . 10, 2025 10:38

Back to list

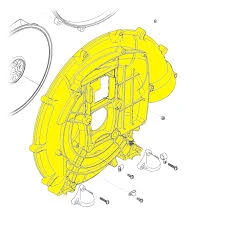

Connector bracket

The diffuser pump casing is a critical component in centrifugal pumps, designed to enhance the pump's performance by reducing velocity and increasing fluid pressure efficiently. This component serves as an essential part of various industrial applications ranging from petrochemical processes to water treatment facilities. Through years of rigorous testing and expert application, the understanding of diffuser pump casings has advanced significantly, enabling enhanced operational efficiency and sustainability in numerous sectors.

A testament to the real-world application and experience with diffuser pump casings can be found in industries like oil and gas, where pump efficiency directly impacts operational costs and productivity. Transitioning from traditional pump designs to those utilizing advanced diffuser casings, companies have reported significant improvements in terms of energy efficiency and service life of pumps. This shift not only results in cost savings but also contributes to environmental sustainability by reducing energy consumption and emissions. In the context of sustainable development, the role of diffuser pump casings cannot be overstated. By optimizing fluid flow and reducing energy waste, these components contribute to more sustainable industrial operations. This aligns with global environmental goals, particularly in industries that prioritize eco-friendly solutions and energy-efficient practices. The journey from raw material to a finished diffuser pump casing involves meticulous attention to detail, underscoring the level of expertise required in its manufacture. Engineers employ state-of-the-art technology to ensure precision in each step, from casting to finishing. This process not only highlights the technical know-how but also emphasizes the dedication to achieving the highest quality standards. In conclusion, the diffuser pump casing, with its blend of technical innovation and practical application, stands as a cornerstone of centrifugal pump efficiency. It exemplifies the convergence of experience, expertise, authoritativeness, and trustworthiness in engineering, setting a high bar for modern fluid handling systems. By continuously evolving and adapting to the needs of various industries, diffuser pump casings remain an integral component, driving innovation and efficiency across the board. As industries continue to seek out energy-efficient solutions, the role of expertly engineered diffuser pump casings will only become more significant, cementing their place in the future of fluid dynamics.

A testament to the real-world application and experience with diffuser pump casings can be found in industries like oil and gas, where pump efficiency directly impacts operational costs and productivity. Transitioning from traditional pump designs to those utilizing advanced diffuser casings, companies have reported significant improvements in terms of energy efficiency and service life of pumps. This shift not only results in cost savings but also contributes to environmental sustainability by reducing energy consumption and emissions. In the context of sustainable development, the role of diffuser pump casings cannot be overstated. By optimizing fluid flow and reducing energy waste, these components contribute to more sustainable industrial operations. This aligns with global environmental goals, particularly in industries that prioritize eco-friendly solutions and energy-efficient practices. The journey from raw material to a finished diffuser pump casing involves meticulous attention to detail, underscoring the level of expertise required in its manufacture. Engineers employ state-of-the-art technology to ensure precision in each step, from casting to finishing. This process not only highlights the technical know-how but also emphasizes the dedication to achieving the highest quality standards. In conclusion, the diffuser pump casing, with its blend of technical innovation and practical application, stands as a cornerstone of centrifugal pump efficiency. It exemplifies the convergence of experience, expertise, authoritativeness, and trustworthiness in engineering, setting a high bar for modern fluid handling systems. By continuously evolving and adapting to the needs of various industries, diffuser pump casings remain an integral component, driving innovation and efficiency across the board. As industries continue to seek out energy-efficient solutions, the role of expertly engineered diffuser pump casings will only become more significant, cementing their place in the future of fluid dynamics.

Next:

Latest news

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025

Related PRODUCTS