Mobile:+86-311-808-126-83

Email:info@ydcastings.com

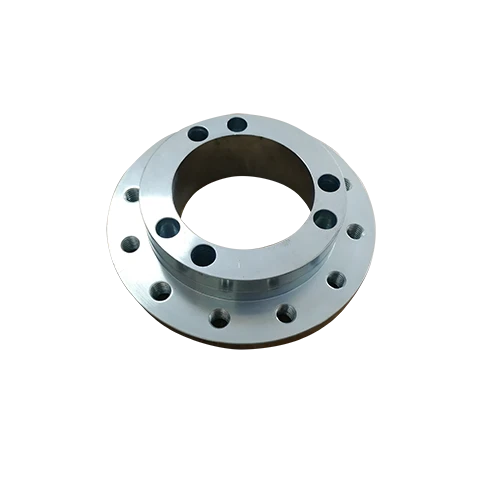

cf8m steel

Understanding CF8M Stainless Steel Composition, Properties, and Applications

CF8M stainless steel is a particularly versatile material in the realm of metallurgy and engineering. This alloy, classified as a cast stainless steel, primarily comprises iron, chromium, nickel, and molybdenum, providing a unique balance of mechanical strength and corrosion resistance. The composition of CF8M typically includes 18% chromium and 8% nickel, along with approximately 2-3% molybdenum, which enhance its resistance to pitting and crevice corrosion.

.

The mechanical properties of CF8M also make it suitable for many industrial applications. It boasts good tensile strength, high ductility, and excellent weldability, enabling it to maintain integrity under a variety of stress conditions. These attributes are essential for components that encounter harsh working environments or require precise manufacturing tolerances. CF8M can be cast into complex shapes and is often used to produce valves, fittings, and pumps, which are crucial in systems that transport fluids.

cf8m steel

Furthermore, CF8M exhibits great thermal properties, including a relatively high melting point and low thermal expansion. This characteristic is critical in applications that experience variations in temperature, as it reduces the risk of thermal stress and associated failures. For this reason, CF8M is often utilized in high-temperature environments, such as in power generation and petrochemical industries, where equipment is subjected to both pressure and temperature fluctuations.

In terms of maintenance, CF8M stainless steel is also advantageous. The smooth surface finish that is achievable with this material helps prevent the accumulation of contaminants, making it easier to clean and sanitize. This is particularly important in industries such as food processing and pharmaceuticals, where hygiene is paramount. Regular maintenance and cleaning of components made from CF8M contribute to their longevity and reliable performance.

Despite its many benefits, it is essential to also consider the limitations of CF8M stainless steel. While it offers excellent resistance to many corrosive agents, it is not suitable for environments that expose it to strong acids like sulfuric acid, which can cause significant degradation. Additionally, it may not perform optimally in extreme cryogenic temperatures or under conditions where extreme mechanical stress is applied, and alternative materials may be recommended in such situations.

In conclusion, CF8M stainless steel is a premier choice for a broad range of applications due to its exceptional combination of corrosion resistance, mechanical strength, and versatility. Whether in chemical processing, food and beverage manufacture, or high-temperature environments, CF8M stands out as a reliable, durable material that meets the demanding requirements of modern industry. As technologies progress and new applications emerge, the relevance of CF8M stainless steel is poised to continue growing, confirming its place as a cornerstone in the field of materials engineering.

-

Unleash Wholesale with YD's Steel Investment CastingNewsAug.04,2025

-

Revolutionize Your Inventory with High-Quality Impeller SolutionsNewsAug.04,2025

-

Power Your Wholesale Business with Premium Electric Power AccessoriesNewsAug.04,2025

-

Elevate Your Wholesale Business with Premium Valve SolutionsNewsAug.04,2025

-

Elevate Your Wholesale Business with Premier Metal Castings SolutionsNewsAug.04,2025

-

Drive Your Wholesale Success with Premium Auto Water Pump SolutionNewsAug.04,2025