Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Similarities Between CF8M and CF3M Stainless Steel Grades

The Impact of CF8M and CF3M in Industrial Applications

In the realm of industrial applications, the choice of materials plays a crucial role in ensuring efficiency, durability, and safety. Among the myriad of materials available, CF8M and CF3M stand out due to their unique properties, making them highly sought after in various industries such as chemical processing, oil and gas, and food production. Understanding the characteristics and applications of these two significant materials enables engineers and manufacturers to make informed decisions that can greatly influence operational success.

What are CF8M and CF3M?

CF8M and CF3M are both alloys classified under the austenitic stainless steel family. The designation CF8M is commonly used for stainless steel castings, which typically contain approximately 18% chromium, 8% nickel, and a small percentage of molybdenum. This composition provides excellent corrosion resistance, high strength, and good machinability. CF8M is often used in the manufacturing of valves, fittings, and other components that require resilience against aggressive environments.

.

Key Differences and Applications

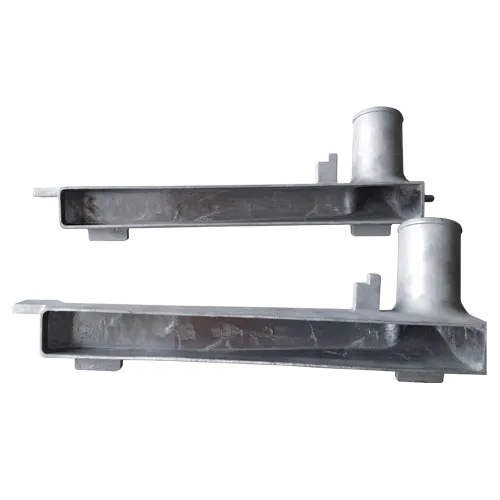

cf8m cf3m

While CF8M and CF3M share a similar base composition, the addition of molybdenum in CF3M offers distinct advantages in specific applications. For example, CF8M is widely utilized in the manufacturing of pumps, valves, and piping systems due to its excellent mechanical properties. Industries such as aerospace, construction, and pharmaceuticals benefit from its robust characteristics and versatility.

Conversely, CF3M’s enhanced corrosion resistance makes it an ideal choice for chemical processing applications and offshore oil rigs, where exposure to harsh environmental conditions is common. It is well-suited for equipment that comes into direct contact with aggressive chemicals or seawater. Choosing the right material is pivotal in preventing costly failures and ensuring safety in operations.

Conclusion

In conclusion, selecting the appropriate material for industrial applications is essential for achieving operational excellence. CF8M and CF3M exemplify the advancements in stainless steel technology, providing manufacturers with reliable options tailored for diverse needs. By understanding the differences between these two alloys, industries can optimize their production processes and maintain high standards of safety and efficiency.

The demand for durable and corrosion-resistant materials like CF8M and CF3M continues to grow, reflecting the ongoing evolution of technology and industrial practices. As industries face ever-increasing challenges, the importance of utilizing the right materials will only become more pronounced, marking a critical step in the pursuit of sustainability and reliability in manufacturing and engineering. By prioritizing the use of high-quality materials, companies can enhance their productivity and maintain competitive advantages in a rapidly changing market landscape.