Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding CF8 and CF8M Stainless Steels Properties and Applications

Understanding CF8 and CF8M Stainless Steels Characteristics, Applications, and Differences

Stainless steel is renowned for its corrosion resistance, strength, and versatility. Among the many grades of stainless steel available, CF8 and CF8M are two important types that are widely used in various industrial applications. Both materials are classified under the austenitic stainless steel category, but they have distinct properties that make them suitable for different environments and usages.

What are CF8 and CF8M?

CF8 and CF8M are both cast stainless steels defined by the American Society for Testing and Materials (ASTM) specifications. CF8 is a grade of stainless steel that corresponds to the ASTM A351 specification, primarily composed of iron, carbon, chromium (about 18%), and nickel (more than 8%). This composition provides CF8 with excellent corrosion resistance and mechanical properties, making it suitable for many applications, particularly in food processing and pharmaceutical industries.

On the other hand, CF8M is an enhanced version of CF8, with molybdenum added to its chemical composition. Typically, CF8M contains around 2-3% molybdenum, which significantly improves its resistance to pitting and crevice corrosion, particularly in chloride environments. This makes CF8M particularly valuable in applications where the material is exposed to harsh chemicals or saline conditions.

Corrosion Resistance and Applications

.

Conversely, CF8M’s superior resistance to corrosion, especially against chlorides, allows it to thrive in more challenging situations. It is commonly utilized in marine applications, chemical processing, and oil and gas industries. The increased molybdenum content enables CF8M to resist corrosion in saltwater environments, making it a preferred choice for offshore platforms, seawater handling, and various industrial applications involving acidic solutions.

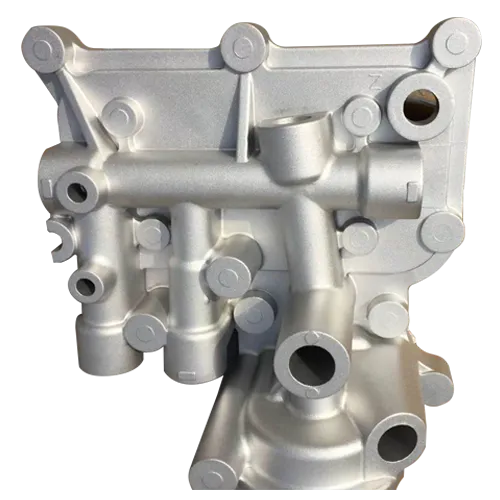

cf8 cf8m

Mechanical Properties

Both CF8 and CF8M exhibit favorable mechanical properties, including good ductility and weldability. However, due to the presence of molybdenum in CF8M, this alloy also displays higher tensile strength and better toughness at elevated temperatures compared to CF8. CF8M's composition allows it to perform well in cryogenic applications and withstand thermal cycling without significant degradation.

Choosing Between CF8 and CF8M

When selecting the appropriate stainless steel for a particular application, the environmental conditions, exposure to corrosive substances, and temperature ranges must be carefully considered. For applications in mild environments with limited exposure to chlorides, CF8 may be a cost-effective choice. Its lower molybdenum content generally leads to a more economical option while still providing adequate corrosion resistance.

However, in scenarios involving aggressive corrosive agents or high-saline environments, CF8M is likely the better option due to its enhanced resistance to pitting and stress corrosion cracking. Although it may come at a higher material cost, the long-term benefits and reduced risk of failure can justify the investment.

Conclusion

In summary, CF8 and CF8M are two vital grades of stainless steel that offer excellent corrosion resistance and versatility in various applications. While CF8 serves well in less demanding environments, CF8M’s enhanced properties make it the go-to option for more corrosive and high-stress situations. Understanding the differences between these two grades can help industries make informed decisions, ensuring the longevity and reliability of their equipment and structures.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025