Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Types of Impellers Used in Centrifugal Pump Design and Applications

Understanding Centrifugal Pump Impeller Types

Centrifugal pumps are widely used in various industries for fluid transport, due to their efficiency and versatility. At the heart of these pumps lies the impeller, a crucial component that influences the pump's performance. There are several types of impellers, each designed with specific characteristics suitable for different applications.

1. Closed Impellers Closed impellers are characterized by having two shrouds that enclose the blades. This design allows for efficient handling of fluids and is effective in generating high fluid pressures. Closed impellers are particularly preferred in applications where the fluid is clean and free of solid particles. They provide excellent performance, minimizing turbulence and improving overall efficiency.

2. Open Impellers Open impellers consist of blades that are not enclosed by shrouds. This design allows for easier passage of fluids containing suspended solids or fibrous materials. Open impellers are ideal for applications involving slurries or wastewater, as they can handle solids without clogging. However, they tend to be less efficient than closed impellers due to increased turbulence and potential for cavitation.

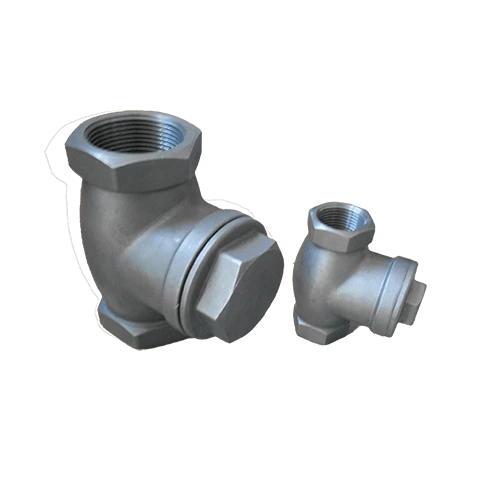

centrifugal pump impeller types

3. Semi-Open Impellers Semi-open impellers strike a balance between closed and open designs. They have one side shrouded and one side open, allowing for better handling of solids while maintaining some efficiency. This type of impeller is useful in applications where the fluid can have moderate levels of impurities. Semi-open impellers are often employed in municipal wastewater treatment plants and industrial processes.

4. Vortex Impellers Vortex impellers are designed to create a swirling flow pattern, allowing them to handle fluids with high solid content without clogging. This design is particularly advantageous in applications such as sewage and slurry pumping. Vortex impellers are efficient in managing low-pressure applications but are not suited for high-pressure needs.

5. Mixed Flow Impellers These impellers combine features of both centrifugal and axial flow pumps. They can handle a range of flow rates and deliver moderate pressures, making them versatile in various applications. Mixed flow impellers are commonly found in medium head pumping scenarios, such as irrigation and drainage.

Choosing the right impeller type is critical for optimizing pump performance and ensuring longevity. Factors such as fluid characteristics, desired flow rates, and pressure requirements should guide the decision-making process. Understanding these different types of centrifugal pump impellers ensures that industries can select the most suitable option for their specific needs, ultimately improving operational efficiency and reducing costs.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025