Mobile:+86-311-808-126-83

Email:info@ydcastings.com

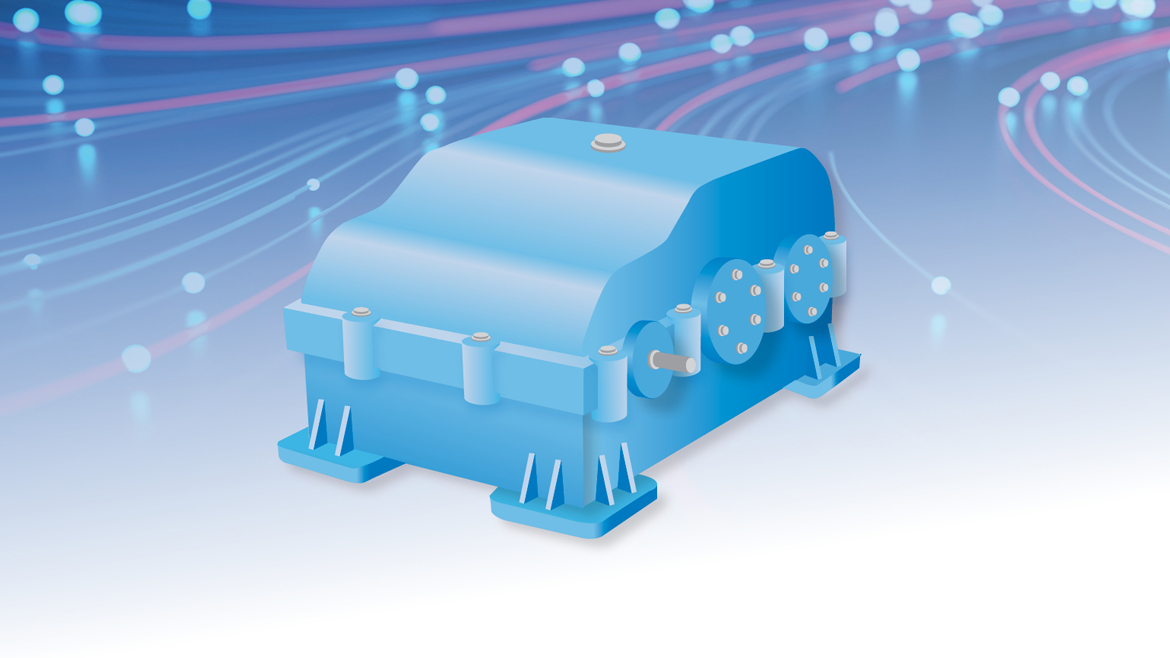

centrifugal blower impeller

Understanding Centrifugal Blower Impellers

Centrifugal blowers are critical components in various industrial applications, from material handling to HVAC systems. Central to their function is the impeller, which plays a key role in generating airflow and pressure. This article delves into the design, operation, and importance of centrifugal blower impellers.

Design of Centrifugal Blower Impellers

Centrifugal blower impellers are typically characterized by their radial blades, which are usually designed in a curved or twisted configuration. This design allows for efficient airflow as the impeller spins. Impellers can vary in size, shape, and material, depending on the specific application requirements. Common materials include aluminum, steel, and composite materials, offering varying degrees of strength, weight, and corrosion resistance.

The geometry of the impeller is crucial. The angle, width, and spacing of the blades can all influence performance metrics such as airflow rate, pressure rise, and efficiency. For instance, blades that are curved backward tend to be more efficient at handling higher flow rates, making them suitable for applications in ventilation and air conditioning.

Operation of Centrifugal Blower Impellers

When the centrifugal blower is activated, the motor drives the impeller, creating rotational motion. As the impeller spins, it draws air into the inlet through the center. The design of the impeller then accelerates this air outward due to centrifugal force, pushing it through a diffuser and into the discharge duct.

centrifugal blower impeller

This process is remarkably effective, as it converts the mechanical energy from the motor into kinetic energy in the form of high-speed airflow. The airflow generated can be adjusted by changing the speed of the motor or the design of the impeller itself, enabling flexibility in various applications.

Importance of Impeller Selection

Choosing the right impeller for a centrifugal blower is essential for optimizing performance. Factors such as the desired airflow rate, pressure requirements, and the specific conditions of the environment (e.g., temperature, humidity, and the presence of particulates) will all influence this decision.

In industrial settings, a poorly selected impeller can lead to inefficiencies, increased energy consumption, and premature wear or failure of the blower. Therefore, careful consideration must be given during the design and engineering phases to ensure that the impeller is well-suited to its intended application.

Conclusion

Centrifugal blower impellers are integral to the efficiency and effectiveness of airflow systems. Their design and operational mechanics determine how well these systems perform. Understanding the intricacies of impeller design and function is vital for engineers and technicians who aim to optimize blower performance across various industrial applications. By selecting the appropriate impeller, industries can enhance efficiency, reduce operational costs, and ensure reliable service in their ventilation and air movement systems. Whether in manufacturing, agriculture, or climate control, the centrifugal blower impeller remains a key player in the pursuit of optimal airflow management.