Mobile:+86-311-808-126-83

Email:info@ydcastings.com

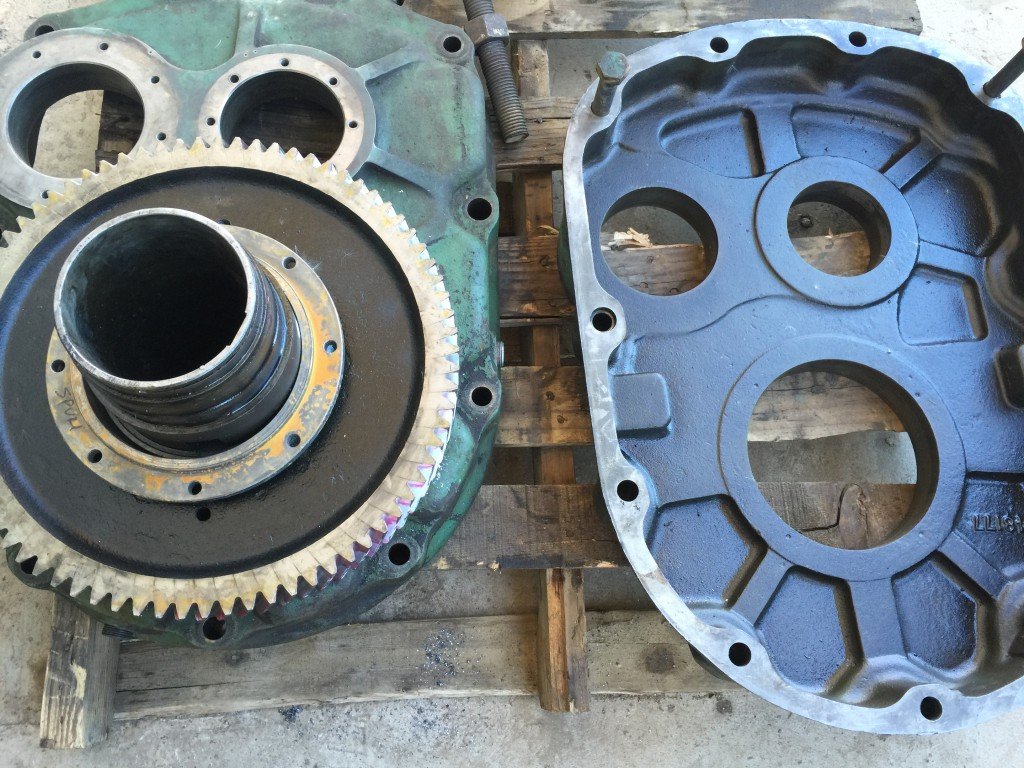

Durable Cast Iron Impeller for Enhanced Performance in Fluid Pumping Applications

The Advantages of Cast Iron Impellers

Cast iron impellers play a vital role in various industrial applications, particularly in the field of pumps, mixing equipment, and ventilation systems. Known for their durability and strength, cast iron impellers are widely recognized for their ability to handle tough operational environments while maintaining consistent performance. This article will explore the advantages of cast iron impellers and their significance in modern engineering.

One of the primary benefits of cast iron impellers is their exceptional strength and rigidity. Cast iron, an alloy of iron that contains carbon, is renowned for its ability to withstand high levels of stress and pressure, making it an ideal material for impeller manufacturing. This robustness allows cast iron impellers to perform effectively in high-flow or high-head applications, where other materials may succumb to wear or breakage. The inherent toughness of cast iron ensures that these impellers can be used in an array of demanding industrial environments, from water treatment plants to heavy machinery.

Another advantage of cast iron impellers is their impressive resistance to wear and corrosion. The casting process used to create these impellers results in a dense, durable structure that can endure abrasive materials without significant degradation over time. This characteristic is particularly beneficial in applications involving particulate-laden fluids or harsh chemical environments. Furthermore, various coatings and treatments can be applied to cast iron impellers to enhance their corrosion resistance, thereby extending their operational lifespan and reducing maintenance costs.

cast iron impeller

Cost-effectiveness is another noteworthy feature of cast iron impellers. Compared to other materials, such as stainless steel or bronze, cast iron is relatively low-cost. This affordability does not come at the expense of performance; instead, it offers an economical solution for industries looking to balance budget constraints with the need for reliable equipment. The ease of manufacturing and availability of cast iron also contribute to lower overall production costs, making it a preferred choice for many applications.

Additionally, cast iron impellers are known for their excellent casting characteristics. The versatility of the material allows for complex designs and shapes, enabling engineers to create impellers optimized for specific applications. This adaptability can significantly enhance a system's overall efficiency by ensuring optimal fluid dynamics and minimal energy loss. The ability to produce large quantities of cast iron impellers without sacrificing quality or precision makes them a popular choice among manufacturers.

In conclusion, cast iron impellers offer a plethora of advantages that make them an indispensable component in many industrial applications. Their strength and durability, coupled with wear and corrosion resistance, cost-effectiveness, and excellent castability, position them as a reliable solution for a wide range of operational requirements. As industries continue to evolve and demand higher performance from their equipment, cast iron impellers will undoubtedly remain a strong contender in the marketplace, providing engineers with a dependable option that meets both functional and economic needs. Whether for pumps, mixers, or ventilation systems, the value of cast iron impellers cannot be overstated.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025