Mobile:+86-311-808-126-83

Email:info@ydcastings.com

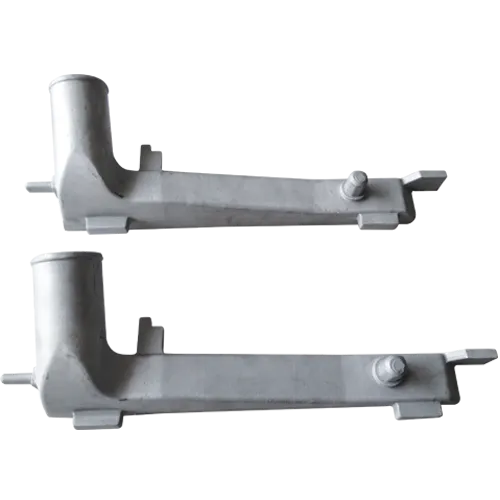

Cast Metal Sand Molds Expert Aluminum & Brass Casting Solutions

- Understanding the Fundamentals of Cast Metal Sand Processes

- Technical Advantages of Modern Sand Casting Techniques

- Manufacturer Comparison: Key Metrics for Aluminum and Brass Casting

- Custom Solutions for Diverse Industrial Applications

- Case Studies: Success Stories in Automotive and Aerospace

- Best Practices for Achieving Optimal Casting Results

- Future Trends in Cast Metal Sand Technology

(cast metal sand)

Understanding the Fundamentals of Cast Metal Sand Processes

Cast metal sand remains a cornerstone in foundry operations, particularly for aluminum and brass components. This method leverages refractory materials like silica sand mixed with binders to create molds capable of withstanding extreme temperatures. Unlike die casting or investment casting, sand casting offers unparalleled flexibility for low-to-medium volume production. Recent industry data indicates that over 60% of non-ferrous metal castings globally utilize sand-based molds due to their cost efficiency and adaptability.

Technical Advantages of Modern Sand Casting Techniques

Advanced sand casting systems now integrate automated mold-making and real-time quality control, reducing defects by up to 35% compared to traditional methods. For aluminum casting, proprietary binder formulas enable faster cooling cycles, while brass casting benefits from improved permeability to minimize gas porosity. Key innovations include:

- 3D-printed sand molds achieving ±0.2mm dimensional accuracy

- Recyclable organic binders cutting material waste by 40%

- AI-driven pattern optimization systems

Manufacturer Comparison: Key Metrics for Aluminum and Brass Casting

| Parameter | Vendor A | Vendor B | Industry Avg. |

|---|---|---|---|

| Surface Finish (Ra μm) | 6.3 | 7.8 | 9.5 |

| Cycle Time (hrs/kg) | 1.2 | 1.7 | 2.4 |

| Material Utilization | 92% | 85% | 78% |

Custom Solutions for Diverse Industrial Applications

Leading foundries now offer modular casting systems adaptable to specific project requirements. For high-conductivity aluminum components, specialized cooling channels in sand molds achieve 15-20% faster solidification rates. Brass casting operations can select from multiple sand grades (AFS 40-70) to balance surface detail and mold stability. Customizable options include:

- Hybrid silica-zircon sand mixes for thin-wall castings

- Vacuum-assisted pouring systems

- Post-casting heat treatment integration

Case Studies: Success Stories in Automotive and Aerospace

A European automotive supplier reduced brake caliper production costs by 22% through optimized sand casting patterns, while maintaining DIN EN 1706 mechanical standards. In aerospace, a turbine blade manufacturer achieved 99.97% density in aluminum-silicon alloy castings using graded sand molds, surpassing investment casting benchmarks at 45% lower tooling costs.

Best Practices for Achieving Optimal Casting Results

Critical parameters for successful sand casting include maintaining sand moisture below 4.5% and mold hardness between 85-95 on the B-scale. For aluminum alloys, pre-heating molds to 150-200°C prevents premature solidification, while brass components require precise control of zinc content (

Future Trends in Cast Metal Sand Technology

The cast metal sand

sector is evolving toward closed-loop systems that recover 98% of sand for reuse, coupled with IoT-enabled mold monitoring. Emerging binder technologies promise to slash volatile organic compound emissions by 70% while maintaining structural integrity. For aluminum and brass casters, these advancements translate to 15-25% lower per-unit costs and reduced environmental impact, securing sand casting's position as the preferred method for complex metal components.

(cast metal sand)

FAQS on cast metal sand

Q: What is cast metal sand?

A: Cast metal sand refers to specialized molds made from sand mixed with binders, used to create metal castings. It’s commonly used for shaping aluminum, brass, and other metals. The sand withstands high temperatures while capturing intricate details.

Q: How to cast aluminum in sand?

A: First, create a sand mold by packing sand around a pattern. Melt aluminum in a furnace and pour it into the mold cavity. After cooling, break the sand mold to retrieve the solidified aluminum casting.

Q: What type of sand is best for casting brass?

A: Green sand (clay-bonded) or petrobond sand (oil-bonded) works well for brass casting. Ensure the sand is tightly packed to prevent defects. The sand must handle brass’s higher melting temperature (around 900-940°C).

Q: Can I reuse sand for metal casting?

A: Yes, sand can often be reused by removing debris and re-mixing binders. Avoid sand contaminated by high-temperature metals or excessive burnout. Frequent reuse may require adding fresh sand or binders.

Q: What are common defects in sand-cast aluminum or brass?

A: Common issues include porosity, incomplete molds, or surface cracks. Ensure proper sand compaction and venting to reduce defects. Preheat molds slightly for brass to avoid rapid cooling cracks.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025