Mobile:+86-311-808-126-83

Email:info@ydcastings.com

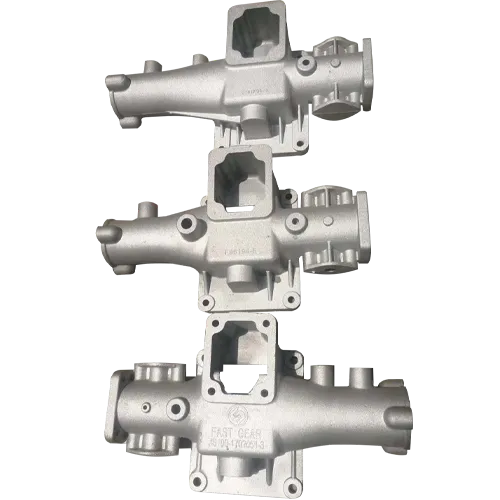

Casing Volute - Efficient Fluid Dynamics Solutions

Understanding Casing Volute in Turbomachinery

Casing volute is a critical component in the design of various turbomachinery, particularly in centrifugal pumps and turbines. It plays a vital role in guiding the fluid from the inlet to the outlet while converting kinetic energy into pressure energy. This article aims to explore the significance of casing volute, its design aspects, and its impact on the performance of turbomachinery.

The casing volute is essentially a spiral-shaped structure surrounding the impeller of a pump or turbine

. Its primary function is to collect the fluid discharged by the impeller and direct it towards the outlet. The volute design is particularly important because it helps in managing the flow path, reducing turbulence, and ensuring a smooth transition of the fluid from the high-speed impeller to the slower-moving discharge area.One of the main advantages of a volute is its ability to transform the high kinetic energy generated by the impeller into static pressure. As the fluid moves through the volute, its cross-sectional area gradually increases. According to Bernoulli’s principle, this increase in area leads to a decrease in fluid velocity, resulting in an increase in pressure. Consequently, the volute minimizes energy losses and enhances the overall efficiency of the turbomachinery.

casing volute

The design of the casing volute must consider several factors, including the geometry of the impeller, the specific application, and the operating conditions. Engineers utilize computational fluid dynamics (CFD) simulations to optimize the volute shape and ensure that the flow remains uniform. Factors such as the volute’s angle, width, and length can significantly influence the hydraulic performance, and careful attention to these parameters can lead to significant improvements in efficiency and reliability.

Furthermore, the material selection for the casing volute is crucial, as they must withstand the mechanical stresses and corrosion associated with the fluid being transported. Common materials include cast iron, stainless steel, and various polymers, each chosen based on the application and environmental conditions.

In conclusion, the casing volute is an integral component of turbomachinery that greatly influences the performance and efficiency of pumps and turbines. Its ability to convert kinetic energy to pressure effectively and manage flow is essential in various applications, from industrial processes to water supply systems. Future advancements in design and materials will likely continue to improve the performance of casing volutes, enhancing the capabilities of turbomachinery in various industries.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025