Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits of Using Bronze Impellers in Modern Applications

The Advantages of Bronze Impellers in Pump Applications

In various industrial applications, the choice of materials for components such as impellers can significantly affect efficiency, longevity, and performance. Among the numerous materials available, bronze has emerged as a popular choice for manufacturing pump impellers. This article explores the advantages of bronze impellers, particularly their mechanical properties, corrosion resistance, and overall performance.

Mechanical Properties

Bronze is an alloy primarily consisting of copper, which may be alloyed with other metals such as tin, aluminum, or nickel. This combination provides bronze with excellent mechanical properties. Bronze impellers are known for their strength and durability. They can withstand high pressures and heavy loads, which is essential in pump applications where performance is crucial. Furthermore, the malleability of bronze allows it to be easily cast and machined into complex shapes, providing manufacturers with the flexibility to design impellers that optimize fluid dynamics.

Corrosion Resistance

One of the standout features of bronze is its superior resistance to corrosion, particularly in marine and freshwater environments. Unlike steel or iron, bronze does not rust, making it an ideal material for pumps that operate in harsh conditions or that are exposed to seawater. This corrosion resistance extends the lifespan of the impeller, reducing maintenance costs and downtime due to repairs or replacements. Additionally, bronze does not suffer from the pitting and crevice corrosion often seen in other metals, ensuring reliable performance over time.

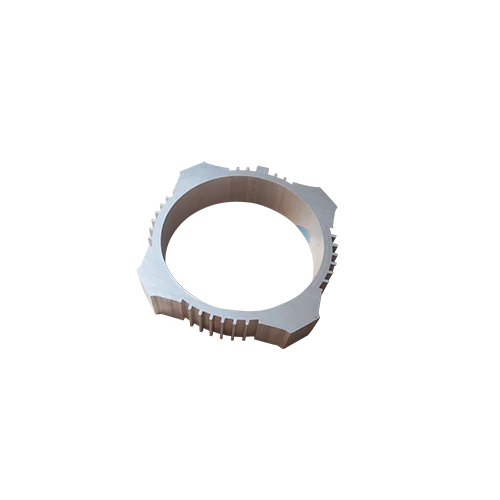

bronze impeller

Performance Efficiency

In pump applications, the efficiency of fluid movement depends heavily on the design and material of the impeller. Bronze impellers exhibit excellent hydrodynamic properties, providing smooth and efficient flow that minimizes energy loss. Their design can be tailored to maximize performance in specific applications, whether it's transferring water, chemicals, or other fluids. Improved efficiency not only reduces energy consumption but also minimizes wear and tear on the pump, contributing to its overall longevity.

Resistance to Cavitation

Cavitation is a phenomenon that occurs when vapor bubbles form in a liquid due to pressure changes, which can lead to significant damage in pumps. Bronze impellers are less susceptible to cavitation than those made from other materials. The inherent properties of bronze allow it to handle the high flow velocities and abrupt pressure changes without succumbing to cavitation damage. This attribute is particularly beneficial in high-performance pumps where operational conditions can fluctuate significantly.

Conclusion

In conclusion, bronze impellers offer numerous benefits that make them an excellent choice for pump applications. Their exceptional mechanical properties, resistance to corrosion, and enhanced performance efficiency ensure that they can withstand the rigors of various industrial environments. Additionally, their resistance to cavitation adds another layer of reliability. For manufacturers and operators looking to optimize their pumping systems, investing in bronze impellers can lead to improved productivity and reduced operational costs in the long run. As industries continue to evolve, the demand for high-quality, durable materials like bronze will undoubtedly remain strong, solidifying its role in the future of pump technology.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025