Mobile:+86-311-808-126-83

Email:info@ydcastings.com

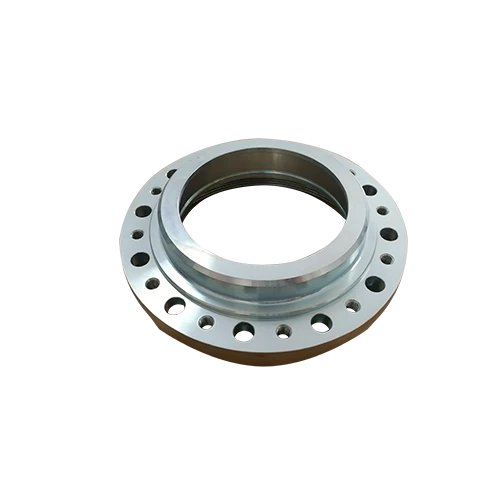

blower impeller

Understanding Blower Impellers A Key Component in Airflow Systems

Blower impellers are fundamental components in various industrial and commercial applications, playing a critical role in the movement of air or gas. These devices are primarily designed to enhance airflow by converting mechanical energy into kinetic energy, facilitating efficient gas transfer. The importance of blower impellers can be observed across multiple sectors, including HVAC (Heating, Ventilation, and Air Conditioning), wastewater treatment, pneumatic conveying, and many more.

Types of Blower Impellers

Blower impellers come in several designs, each suited for specific applications. The two most common types are centrifugal and positive displacement impellers.

1. Centrifugal Impellers Centrifugal impellers utilize rotational kinetic energy to direct air or gas. They are characterized by their fan-like structure, which consists of blades that spin at high speeds to accelerate the airflow outward from the center. This design results in a stable and continuous airflow, making centrifugal impellers ideal for high-pressure applications. They are commonly used in HVAC systems and industrial blowers.

2. Positive Displacement Impellers Positive displacement impellers function by trapping a fixed volume of air or gas and forcing it out through the discharge. This type of impeller is known for its ability to generate consistent airflow regardless of pressure fluctuations. Positive displacement blowers are widely used in applications requiring a steady flow, such as in pneumatic conveying and vacuum systems.

Impeller Design Considerations

When designing a blower impeller, several factors must be taken into consideration to ensure optimal performance

- Material Selection Impellers are typically made from various materials such as metal, plastic, or composites. The choice of material depends on the specific application requirements, including temperature, pressure, and corrosiveness of the gases being moved. For instance, stainless steel is commonly used for its strength and resistance to corrosion, while thermoplastics may be chosen for lighter applications.

- Blade Shape and Angle The shape and angle of the impeller blades significantly influence airflow efficiency and pressure generation. Curved blades tend to provide more efficient airflow than straight blades, while the angle can affect the volume and velocity of the air produced.

blower impeller

- Size and Speed The size of the impeller and its rotational speed are critical in determining the airflow rate and pressure. A larger impeller typically moves more air, while a higher rotational speed increases the kinetic energy of the airflow.

Applications of Blower Impellers

Blower impellers are employed in a variety of applications, showcasing their versatility. In HVAC systems, they are crucial for circulating air throughout residential and commercial buildings, ensuring comfort during extreme weather conditions. In wastewater treatment plants, blower impellers provide the necessary aeration to facilitate biological processes essential for breaking down organic waste.

In the manufacturing sector, pneumatic conveying systems utilize blower impellers to transport bulk materials such as grains, powders, and pellets. The consistent and controlled airflow enables efficient processing and minimizes waste, thereby enhancing productivity.

Maintenance and Optimization

Maintaining blower impellers is essential for ensuring optimal performance and longevity. Regular inspections should be conducted to identify wear and tear, especially in high-demand applications. Cleaning the impellers from dust and debris accumulation can improve efficiency and extend their operational lifespan.

Furthermore, optimization techniques can enhance the performance of blower impellers. Adjusting the operational speed, using variable frequency drives, and retrofitting with more efficient blade designs can lead to significant energy savings and improved airflow.

Conclusion

Blower impellers are indispensable components in numerous industries that rely on efficient air or gas movement. Their diverse designs and applications underline the complexity and importance of these devices in modern technology. By understanding the design considerations, types, and maintenance practices associated with blower impellers, industries can optimize performance, ensure reliability, and maximize energy efficiency in their operations. As technology continues to advance, the evolution of blower impeller designs will likely provide even more efficient solutions for a wide array of applications, contributing to improved operational efficiencies and sustainability in the long run.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025