Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Performance of Blower Fan Impellers for Enhanced Airflow Efficiency

Understanding Blower Fan Impellers Key Components of Airflow Efficiency

Blower fans are critical components in various industrial and commercial applications, serving to move air or gas efficiently. One of the most vital parts of a blower fan is the impeller. This article will delve into the significance of blower fan impellers, their design, functionality, and how they impact the overall performance of blower fans.

What is a Blower Fan Impeller?

An impeller in a blower fan refers to the rotating component that imparts energy to the air or gas, increasing its pressure and velocity. The design of the impeller directly influences the fan's ability to move air efficiently and effectively. Impellers come in various shapes, sizes, and materials, tailored to meet specific operational requirements.

Types of Impellers

Impellers can be categorized into two main types radial and axial.

1. Radial Impellers These impellers move air perpendicularly to the axis of rotation, generating high pressure. They are commonly used in applications requiring a significant increase in air pressure, such as in HVAC systems and industrial processes. The design typically features backward-curved blades, which enhance efficiency and reduce energy consumption.

2. Axial Impellers Axial impellers, on the other hand, push air parallel to the axis of rotation. They are generally more suited for applications where high airflow volume is needed, but less pressure increase is required. Fans fitted with axial impellers are widely used in cooling systems and ventilation.

Design Considerations

When designing a blower fan impeller, several factors must be considered to optimize performance

. These include- Blade Geometry The shape and angle of the blades affect how air flows over them, thus influencing efficiency and performance. Blade curvature, width, and spacing are meticulously calculated to achieve the desired airflow and pressure.

- Material Selection The choice of material for the impeller is crucial, particularly in applications dealing with abrasive or corrosive substances. Common materials include aluminum, plastic, and stainless steel, each offering different durability and weight characteristics.

- Balance and Structural Integrity Impellers must be precisely balanced to reduce vibration and noise during operation. An imbalanced impeller can lead to premature wear on bearings and other components, affecting the longevity of the blower fan.

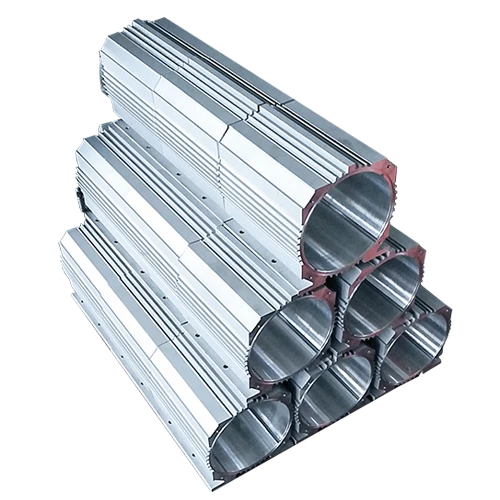

blower fan impeller

Impact on Performance

The performance of a blower fan is heavily influenced by its impeller design. An efficient impeller will

- Enhance Airflow The primary function of the impeller is to move air. A well-designed impeller optimizes the airflow rate, ensuring that the necessary volume of air is delivered for effective cooling or ventilation.

- Increase Pressure Especially in radial designs, the impeller increases the air pressure, which is essential for many industrial applications requiring the transportation of air through ducts and other system components.

- Reduce Energy Consumption Well-engineered impellers achieve optimal performance with minimal energy use. This not only lowers operating costs but also contributes to environmental sustainability by reducing the overall carbon footprint of the system.

Maintenance and Care

To ensure the longevity and efficiency of blower fan impellers, regular maintenance is essential. This includes

- Inspection for Wear Regularly checking for signs of wear or damage helps identify issues before they lead to failure.

- Cleaning Dust and debris can accumulate on the blades, reducing efficiency. Periodic cleaning is necessary to maintain optimal airflow.

- Lubrication Keeping bearings adequately lubricated helps minimize friction and prolongs the life of the impeller.

Conclusion

In summary, the blower fan impeller is a fundamental component that dictates the performance and efficiency of air-moving systems. Understanding its types, design considerations, and operational characteristics is crucial for any application relying on blower fans. With proper design, material selection, and maintenance, blower fan impellers can deliver optimal performance, enhancing airflow, increasing pressure, and ultimately leading to energy-efficient operations in various applications. As technology advances, we can expect even more innovative designs, making these essential components even more effective in meeting the demands of modern industries.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025